Numerical Study on Dynamic Responses and Failure Behaviours of Aramid Fabrics Subject to Blast Loads

-

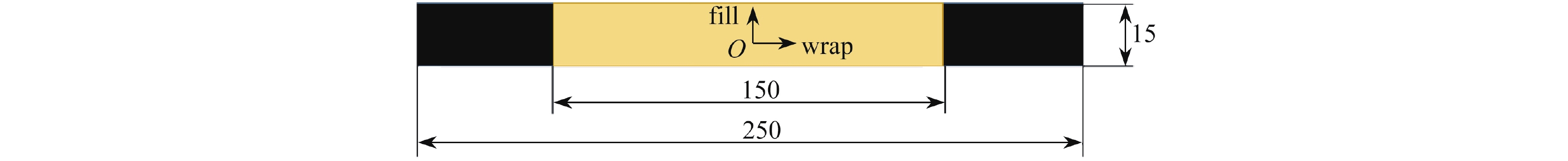

摘要: 为了研究柔性纤维织布的抗爆性能,通过数值模拟的方法对芳纶纤维织布在爆炸冲击下的响应与失效行为进行了分析。对国产芳纶纤维织布H1000D-AP220进行了力学性能试验,建立了柔性平纹织布的本构模型和爆炸冲击数值分析模型,对不同厚度不同铺层角度织布进行了爆炸冲击数值分析,获得了织布在不同爆炸载荷下的动态响应和失效模式。结果表明,织布在爆炸冲击载荷下主要表现为中心撕裂破孔和简支边界处拉伸撕裂2种典型的失效模式,并伴有明显褶皱,宽度方向出现织布向内侧收缩翻转现象;相比于中间层织布,迎爆面和背爆面吸能较多;在计算分析中改变了织布的层叠角度,获得了更好的抗爆效果。Abstract: In order to study the anti-blast performance of flexible fabrics, the dynamic response and failure behavior of aramid fabric under blast impact were analyzed with the numerical simulation method. Mechanical tests of aramid fabric H1000D-AP220 were carried out, and the constitutive model for woven fabric and the explosive numerical analysis model were established. The dynamic responses and failure modes of the fabrics under different loads were obtained by the analysis of fabrics with different thicknesses and different stacking angles. The results show that, there are 2 typical failure modes of fabrics under the explosive impact: the failure of the central hole and the tensile tear at the boundary, with obvious folds in the width direction of the fabric. The front and back layers absorb more energy than the middle ones. Better anti-explosion ability can be achieved through adjustment of the fabric stacking angle.

-

Key words:

- aramid fabric /

- blast impact /

- dynamic response /

- failure mode /

- numerical analysis

-

表 1 芳纶织布的主要参数指标

Table 1. Parameters of the aramid fabric

area density ρa / (g/m2) yarn linear density D/ tex thickness T/ mm yarn cross-sectional area C/ mm2 fabric density R/(root/10 cm) 217 111.1 0.31 0.157 94 表 2 准静态拉伸试验矩阵

Table 2. Quasi-static tensile test matrix

test type direction tensile rate VT /(mm/min) quantity quasi-static warp 20 3 fill 20 3 表 3 动态拉伸试验矩阵

Table 3. The dynamic tensile test matrix

test №. test type direction strain rate $\dot \varepsilon $/ s−1 1 dynamic warp 474 2 512 3 660 4 724 表 4 材料模型参数输入值

Table 4. Material model parameters

variable description unit value RO density g/mm3 0.000 7 EA modulus of elasticity in the warp direction GPa 32 EB modulus of elasticity in the fill direction GPa 30 EACRF factor for the crimp region modulus of elasticity in the warp direction − 0.28 EBCRF factor for the crimp region modulus of elasticity in the fill direction − 0.21 EACRP crimp strain in the warp direction − 0.003 1 EBCRP crimp strain in the fill direction − 0.004 3 EASF factor for the post-peak region modulus of elasticity in the warp direction − −5.24 EBSF factor for the post-peak region modulus of elasticity in the fill direction − −4.67 EAMAX strain at the peak stress in the warp direction − 0.034 EBMAX strain at the peak stress in the fill direction − 0.034 SIGPOST stress value in the post-peak region where nonlinear behavior begins MPa 70 C strain rate parameter s−1 0.5 P strain rate parameter − 3.0 DFAC damage factor − 0.3 EMAX erosion strain of the element − 0.3 EAFAIL erosion strain in the warp direction − 0.2 EBFAIL erosion strain in the fill direction − 0.2 表 5 试验和数值分析结果对比

Table 5. Comparison of test and numerical analysis results

test №. number of fabric layers initial velocity ${V_{\rm{i}}}$ /(m/s) residual velocity ${V_{\rm{r}}}$ /(m/s) absorbed energy percent $\Delta E$ /% ${\delta _{{\rm{AEPD}}}}$/% test simulation test simulation 1 2 137.4 130.4 121 9.93 22.4 −12.47 2 4 129.8 106.0 112 33.3 25.5 7.8 3 6 133.8 85.8 71.6 58.9 71.4 −12.5 4 8 131.8 0 0 1 1 0 5 6 122.0 22.27 15.6 96.7 98.4 −1.7 6 6 152.4 103.8 98.5 53.6 58.2 −4.6 表 6 TNT材料参数

Table 6. Material properties of TNT

variable value density ρTNT/( kg/m3) 1 630 detonation velocity ${V_{\rm{D} } }/\rm{(m/s)}$ 6 930 Chapman-Jouget pressure ${p_{ {\rm{C} }{\text{-} }{\rm{J} } } } /\rm{GPa}$ 21 A/GPa 3 740 B/GPa 3.74 R1 4.15 R2 0.9 ω 0.35 E0/(MJ/m3) 6 000 表 7 空气材料参数

Table 7. Material properties of air

variable value density ρa /( kg/m3) 1.29 C4 0.4 C5 0.4 E0 /(MJ/m3) 0.25 V0 1 表 8 数值分析矩阵

Table 8. The matrix of numerical analysis

simulation №. charge M/g distance S/mm fabric thickness T/mm 1 20 150 3 2 6 3 9 4 60 100 6 5 9 6 12 -

[1] KERBER A, MOURITZ A P. Explosive blast damage resistance of three-dimensional textile composites[J]. Composites, Part A: Applied Science and Manufacturing, 2017, 100: 170-182. doi: 10.1016/j.compositesa.2017.05.005 [2] GARGANO A, PINGKARAWAT K, BLACKLOCK M. Comparative assessment of the explosive blast performance of carbon and glass fibre-polymer used in naval ship structures[J]. Composite Structures, 2017, 171(1): 306-316. [3] HUA Y, AKULA P K, GU L X. Experimental and numerical investigation of carbon fiber sandwich panels subjected to blast loading[J]. Composites (Part B): Engineering, 2014, 56: 456-463. doi: 10.1016/j.compositesb.2013.08.070 [4] BAŞTÜRK S, UYANIK H, KAZANCI Z. Nonlinear damped vibrations of a hybrid laminated composite plate subjected to blast load[J]. Procedia Engineering, 2014, 88: 18-25. doi: 10.1016/j.proeng.2014.11.121 [5] HAGHI R, BEHJAT B, YAZDANI M. Numerical investigation of composite structures under blast loading[J]. Journal of Materials and Environmental Science, 2017, 8: 2231-2237. [6] LI J T, HUANG C, MA T. Numerical investigation of composite laminate subjected to combined loadings with blast and fragments[J]. Composite Structures, 2019, 214: 335-347. doi: 10.1016/j.compstruct.2019.02.019 [7] LANGDON G S, CANTWELL W J, GUAN Z W, et al. The response of polymeric composite structures to air-blast loading: a state-of-the-art[J]. International Materials Reviews, 2014, 59: 159-77. doi: 10.1179/1743280413Y.0000000028 [8] PORFIRI M, GUPTA N. A Review of Research on Impulsive Loading of Marine Composites, Major Accomplishments in Composite Materials and Sandwich Structures[M]. Dordrecht: Springer, 2009. [9] MOURITZ A P. Advances in understanding the response of fibre-based polymer composites to shock waves and explosive blasts[J]. Composites(Part A): Applied Science and Manufacturing, 2019, 125: 105502. doi: 10.1016/j.compositesa.2019.105502 [10] GRUJICIC M, ARAKERE G, HE T. A ballistic material model for cross-plied unidirectional ultra-high molecular-weight polyethylene fiber-reinforced armor-grade composites[J]. Materials Science & Engineering A, 2008, 498(1/2): 231-241. [11] FALLAH A S, MICALLEF K, LANGDON G S. Dynamic response of Dyneema® HB26 plates to localised blast loading[J]. International Journal of Impact Engineering, 2014, 73: 91-100. doi: 10.1016/j.ijimpeng.2014.06.014 [12] ZHANG B, NIAN X, JIN F. Failure analyses of flexible ultra-high molecular weight polyethylene (UHMWPE) fiber reinforced anti-blast wall under explosion[J]. Composite Structures, 2018, 184: 759-774. doi: 10.1016/j.compstruct.2017.10.037 [13] DONATO Z, SAMUELE A, ALESSANDRO B. Textile-based luggage containers for onboard blast protection[J]. Sae International Journal of Aerospace, 2011, 4(2): 690-698. doi: 10.4271/2011-01-2517 [14] FILIPPO M, MARIA M P, PAOLO V. Blast actions in aircrafts: an integrated methodology for designing protection devices[J]. Engineering Structures, 2018, 175: 895-911. doi: 10.1016/j.engstruct.2018.08.082 [15] STAHLECKER Z, MOBASHER B, RAJAN S D. Development of reliable modeling methodologies for engine fan blade out containment analysis, part Ⅱ: finite element analysis[J]. International Journal of Impact Engineering, 2009, 36(3): 447-459. doi: 10.1016/j.ijimpeng.2008.08.004 [16] ZHU D, VAIDYA A, MOBASHER B. Finite element modeling of ballistic impact on multi-layer Kevlar 49 fabrics[J]. Composites (Part B): Engineering, 2014, 56: 254-262. doi: 10.1016/j.compositesb.2013.08.051 [17] COWPER G R, SYMONDS P S. Strain hardening and strain rate effect in the impact loading of cantilever beams: NR-064-406[R]. Providence: Brown University, 1957. [18] 冯振宇, 裴惠, 迟琪琳, 等. Kevlar织物软壁包容环抗冲击数值仿真分析研究[J]. 振动与冲击, 2020, 39(10): 15-23. (FENG Zhenyu, PEI Hui, CHI Qilin, et al. Investigation on the high speed impact numerical simulation of Kevlar fabrics soft-wall containment[J]. Vibration and Shock, 2020, 39(10): 15-23.(in Chinese) [19] REVILOCK D M, PEREIRA J M. Explicit finite element modeling of multilayer composite fabric for gas turbine engine containment systems, phase Ⅱ, part 2: ballistic impact testing: DOT/FAA/AR-08/37 P2[R]. Springfield, Virginia: National Technical Information Service (NTIS), 2009. -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号