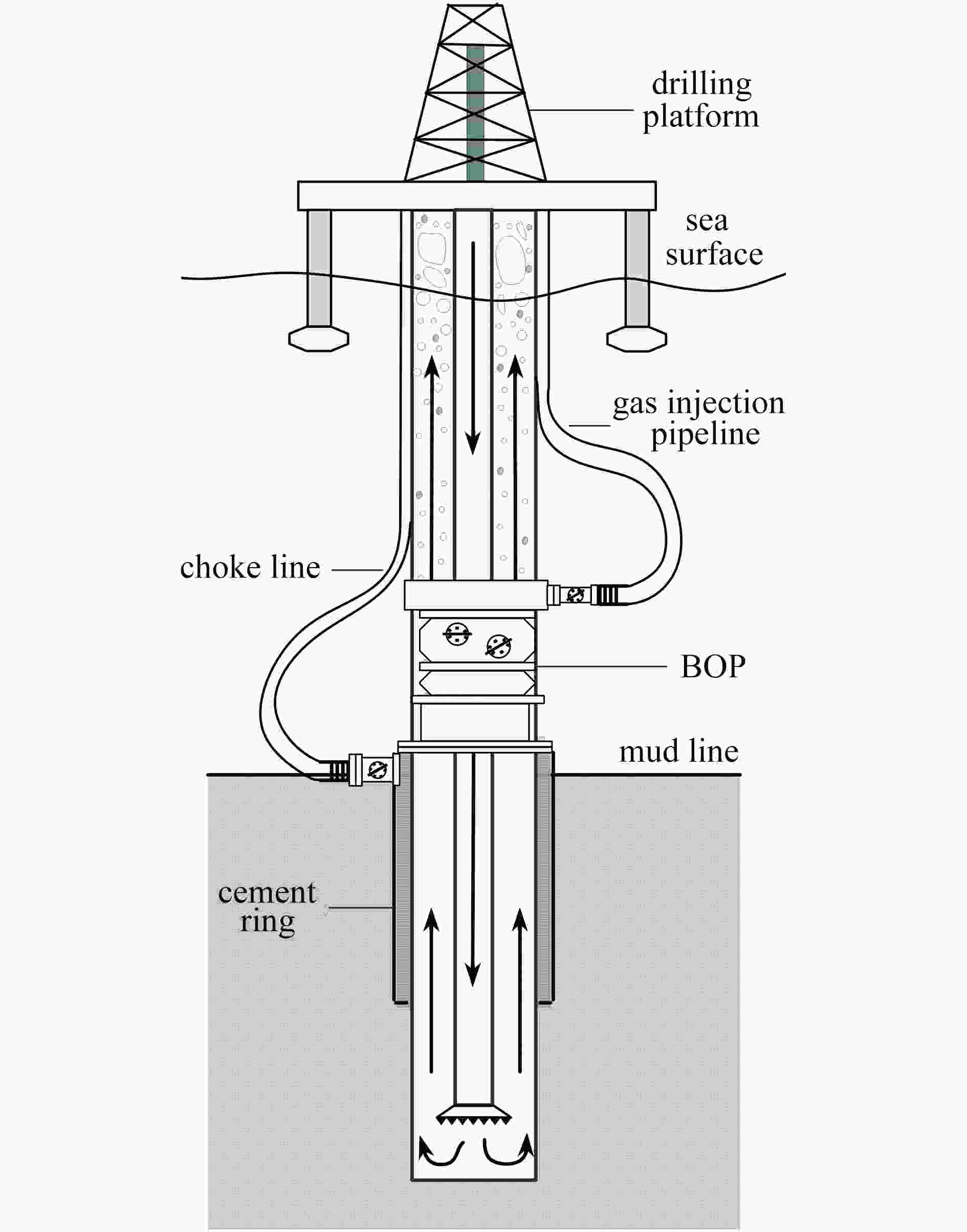

Research on Calculation of Riser Gas Injection Dual-Gradient Drilling Wellbore Parameters

-

摘要:

基于隔水管注气双梯度钻井过程中隔水管环空多相流特性,建立了隔水管注气双梯度钻井环空多相流模型,采用有限差分法对模型进行求解,结合墨西哥湾某口深水井现场数据,分析了钻井参数对井底压力和环空压力的影响,并对注气流量的影响因素进行讨论。研究结果表明:隔水管注气双梯度钻井井底压力比常规钻井更低,更适用于海底窄密度窗口钻井;隔水管注气双梯度钻井在钻井过程中注气流量的大小对井底压力和环空压力影响较大;水深和钻井液密度是影响注气流量的两个重要因素。在隔水管注气双梯度钻井参数设计时,应选择合适的注气流量,且钻井液密度不宜过大,以确保隔水管注气双梯度钻井安全。该研究对隔水管注气双梯度钻井设计及现场作业具有指导意义。

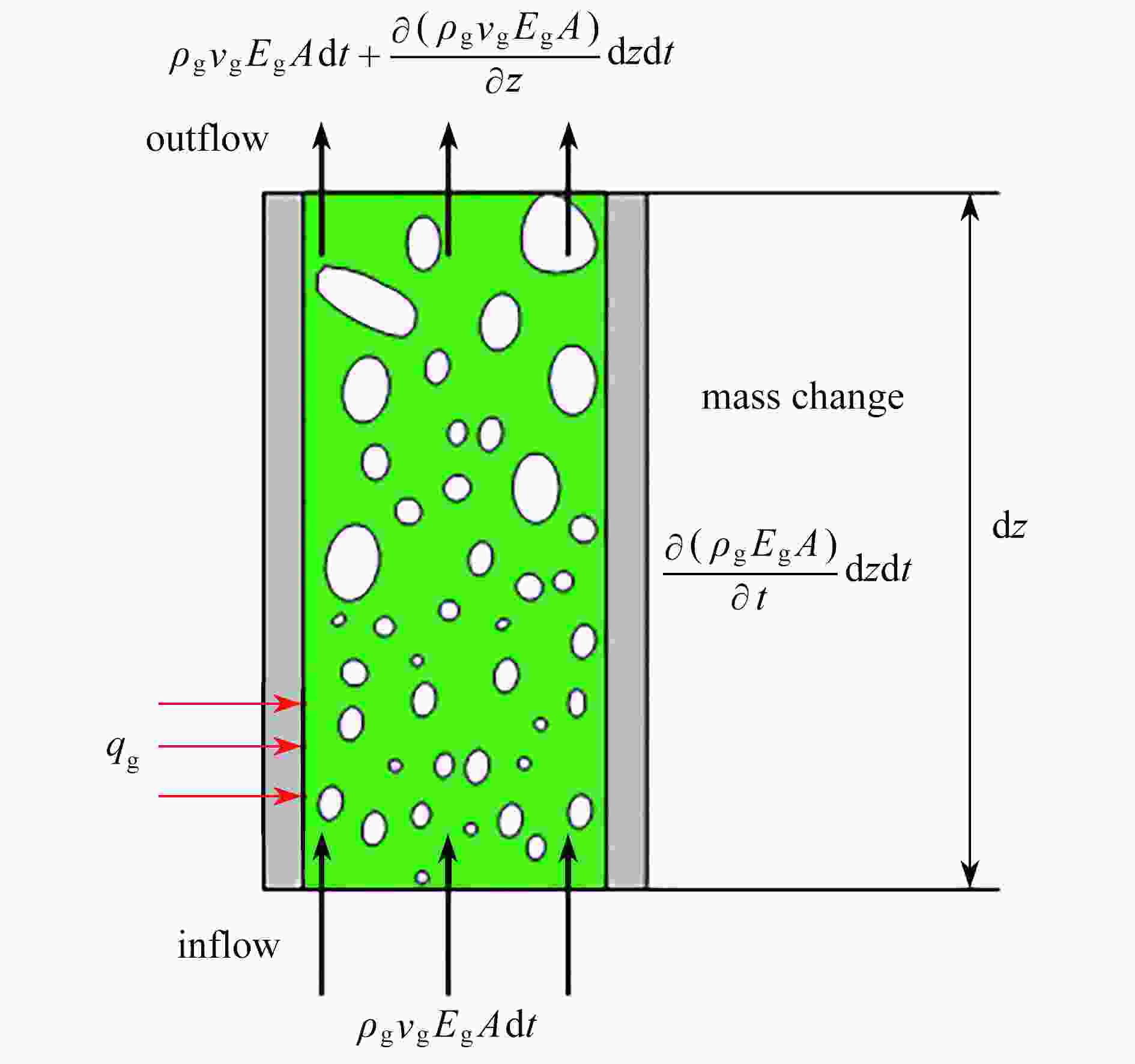

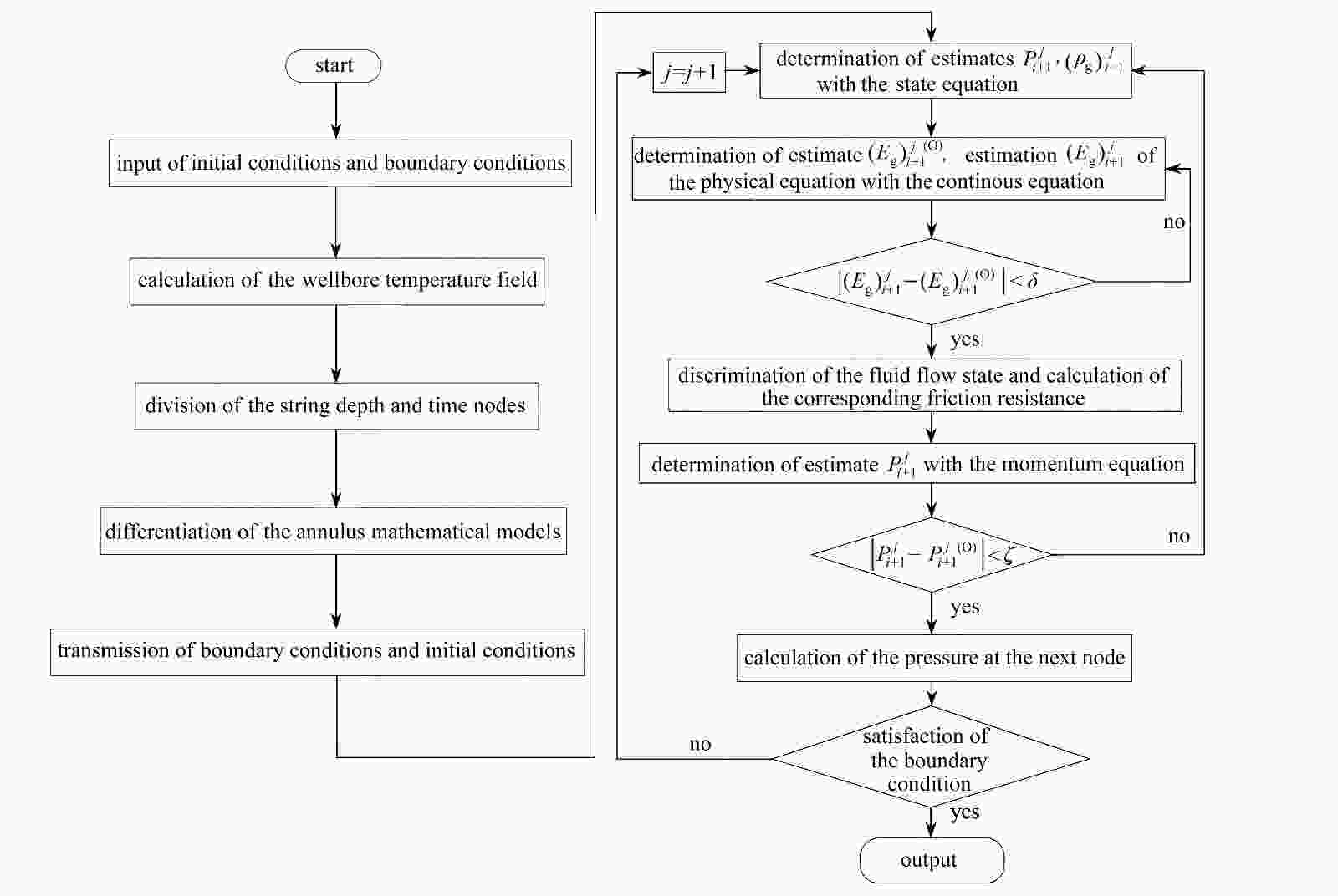

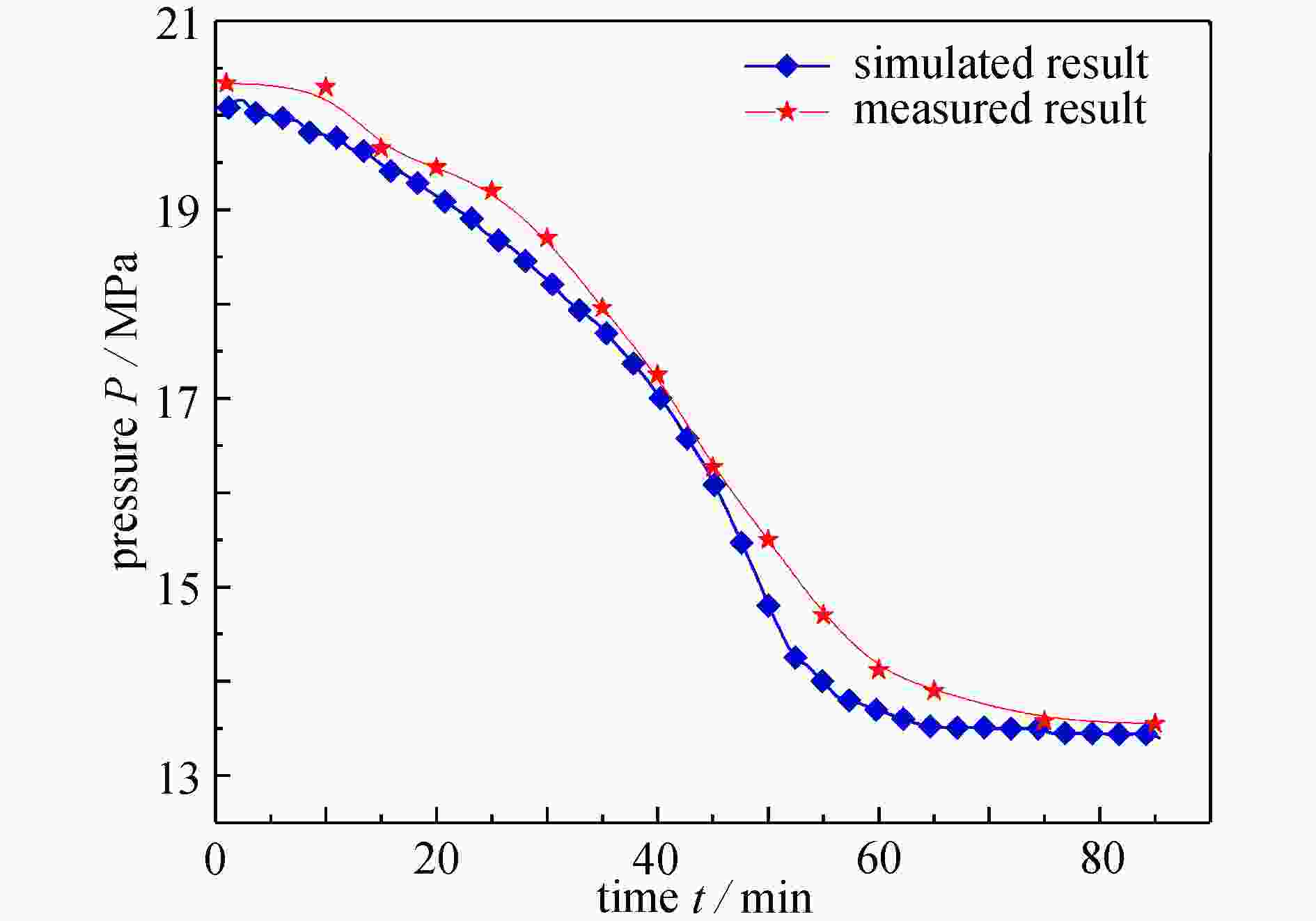

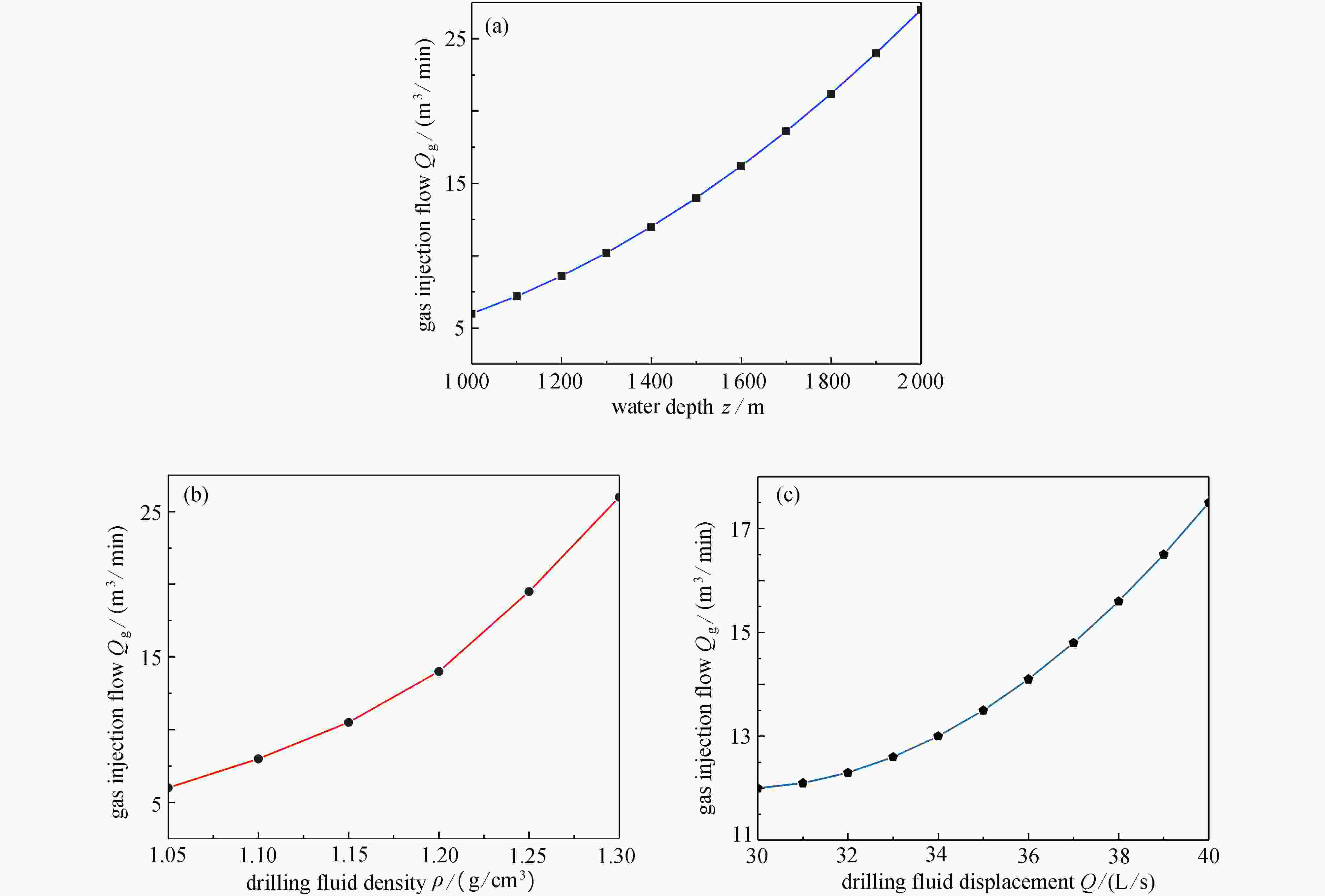

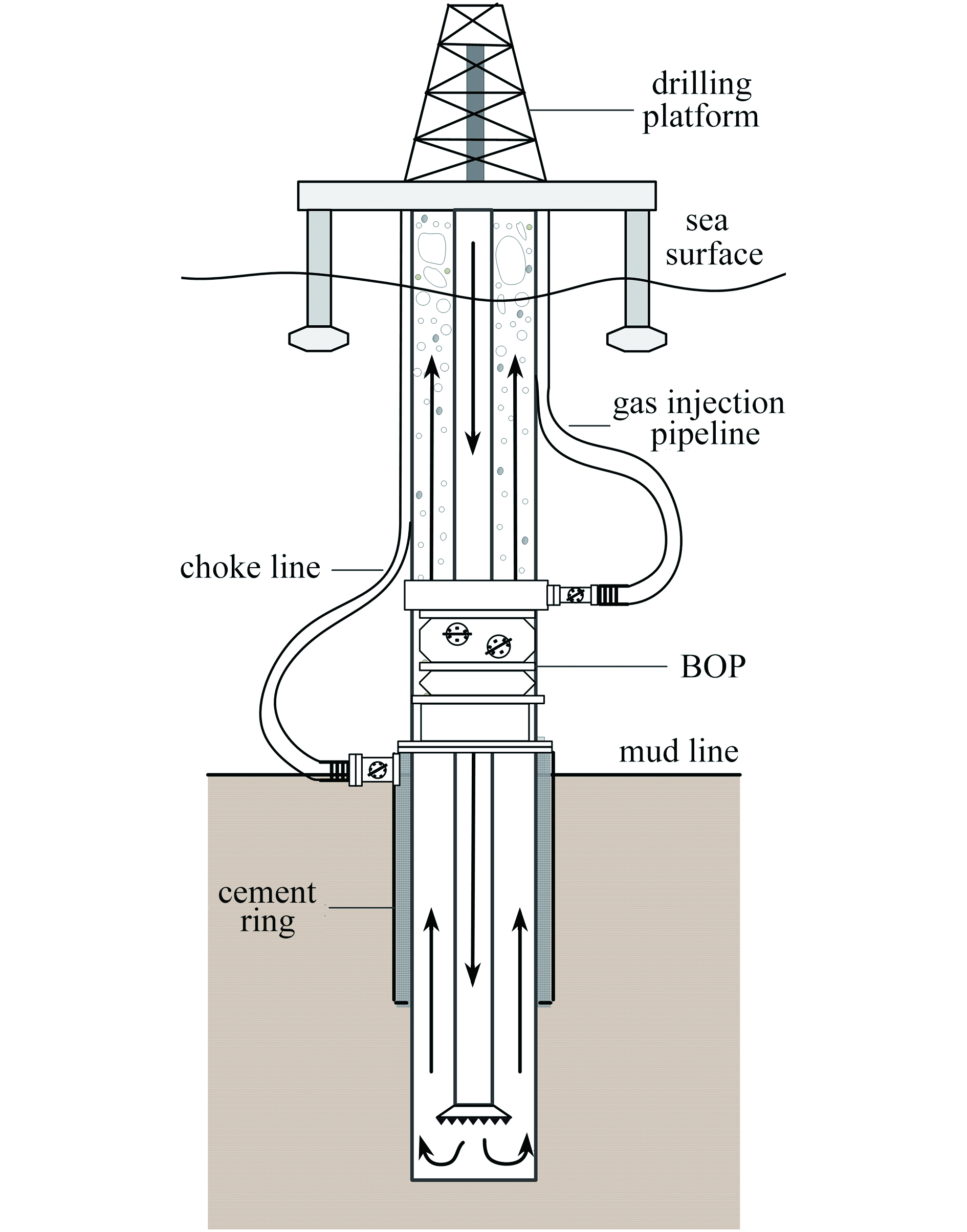

Abstract:Based on the characteristics of multiphase flow in riser annulus during dual-gradient drilling with riser gas injection, a multi-phase flow model for the riser gas injection dual-gradient drilling wellbore was established. The model was solved with the finite difference method and combined with the actual parameters of a deep water well in the Gulf of Mexico. The influences of drilling parameters on the bottom hole pressure and the annulus pressure, and the influence factors on the gas injection flow rate were discussed. The research results show that, the bottom hole pressure of dual-gradient riser gas injection drilling is lower than that of conventional drilling, and is more suitable for subsea narrow-density window drilling; the magnitude of the gas injection flow rate during the dual-gradient riser gas injection drilling process has great effects on the bottom hole pressure and the annulus pressure, and the water depth as well as the drilling fluid density are 2 important factors influencing the gas injection flow. In the design of the dual-gradient drilling parameters for riser gas injection, the appropriate gas injection flow rate should be selected and the drilling fluid density should not be too large to ensure the safety of dual-gradient riser gas injection drilling. The research has guiding significance for the design of dual-gradient drilling with riser gas injection and field operations.

-

Key words:

- deep water /

- dual-gradient /

- multiphase flow /

- gas injection /

- narrow density window

-

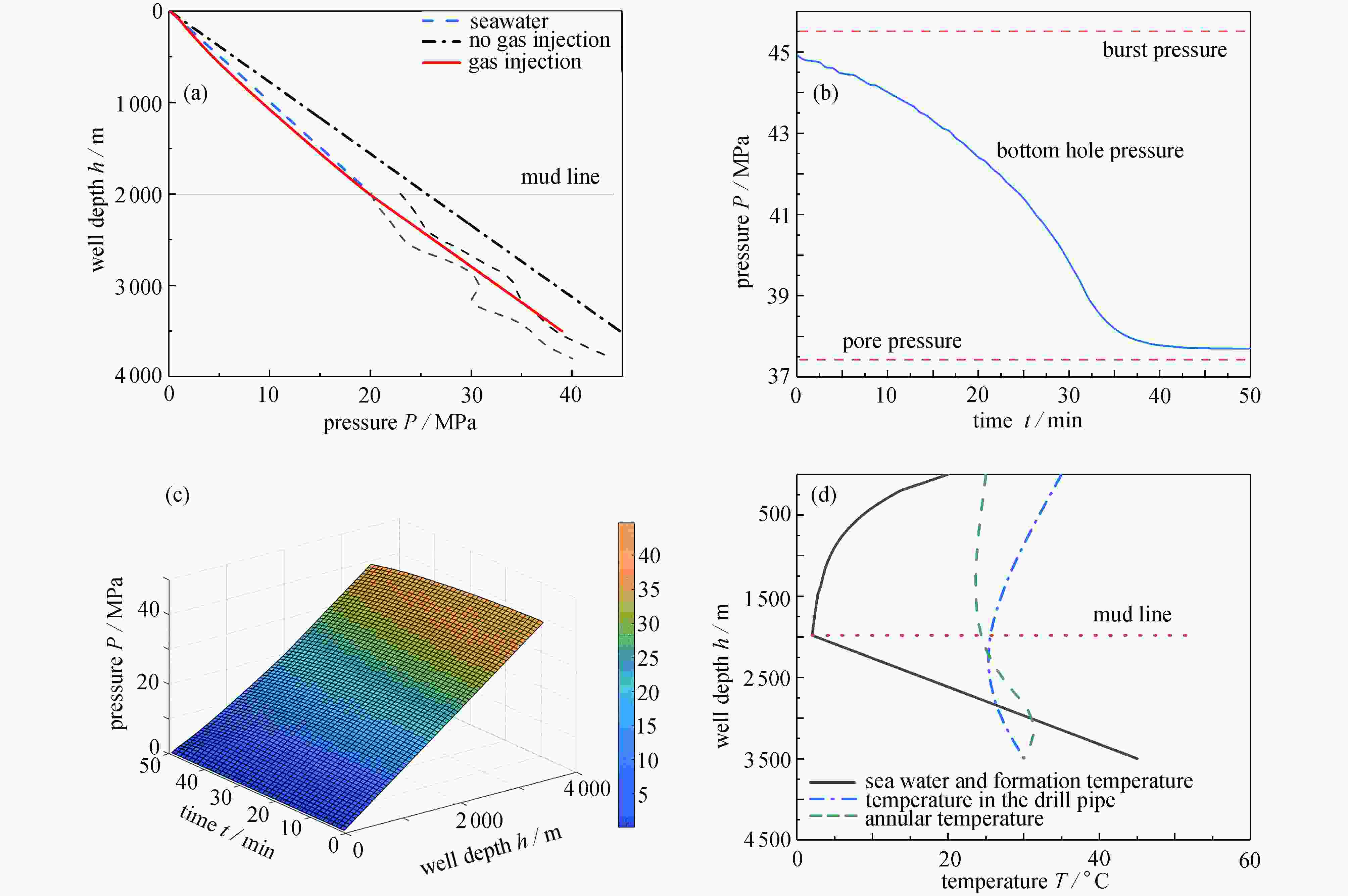

图 6 隔水管注气双梯度钻井注气过程中压力及温度变化:(a) 注气双梯度钻井和常规钻井环空压力分布;(b) 注气双梯度钻井井底压力;(c) 环空压力云图;(d) 井筒温度场变化规律

Figure 6. During the gas injection process of dual-gradient drilling with riser gas injection: (a) the annulus pressure distributions in dual-gradient drilling and conventional drilling; (b) the bottom hole pressure in dual-gradient drilling with gas injection; (c) the annulus pressure contour ; (d) variation laws of the wellbore temperature field

表 1 墨西哥湾某口深水井基础数据

Table 1. Basic data of a deep water well in the Gulf of Mexico

parameter value unit well depth 7132 m water depth 1828 m riser ID 488 mm choke line ID 114 mm casing OD 298.45 mm casing ID 273 mm drilling fluid density 1.12 g/cm3 drilling fluid displacement 34 L/s formation pressure 119.4 MPa nitrogen injection rate 22 m3/min gas injection pipeline ID 31.75 mm drill pipe OD 88.9 mm geothermal gradient 0.03 ℃/m plastic viscosity 28 mPa·s 表 2 墨西哥湾某口深水井相关计算参数

Table 2. Related calculation parameters of a deep-water well in the Gulf of Mexico

parameter value unit water depth 1980 m well depth 3498 m drilling fluid density 1.2 g/cm3 drilling fluid viscosity 31 mPa·s riser ID 488 mm choke line ID 114 mm casing OD 298.45 mm casing ID 273 mm drilling fluid displacement 34 L/s gas injection flow 15 m3/min sea water density 1.02 g/cm3 drill pipe OD 127 mm gas injection pipeline ID 31.75 mm geothermal gradient 0.03 ℃/m gas injection pipeline diameter 88.9 mm -

[1] 王焕平. 双密度钻井技术[J]. 中国石油和化工标准与质量, 2013, 33(9): 50-52. (WANG Huanping. Dual-density drilling technology[J]. China Petroleum and Chemical Standards and Quality, 2013, 33(9): 50-52.(in Chinese) doi: 10.3969/j.issn.1673-4076.2013.09.052 [2] 陈国明, 殷志明, 许亮斌, 等. 深水双梯度钻井技术研究进展[J]. 石油勘探与开发, 2007, 34(2): 246-251. (CHEN Guoming, YIN Zhiming, XU Liangbin, et al. Review of deepwater dual gradient drilling technology[J]. Petroleum Exploration and Development, 2007, 34(2): 246-251.(in Chinese) doi: 10.3321/j.issn:1000-0747.2007.02.023 [3] 陈磊, 郭昭学, 孙凯, 等. 海洋深水钻井技术研究[J]. 天然气技术, 2009, 3(6): 37-39, 79. (CHEN Lei, GUO Zhaoxue, SUN Kai, et al. Research on offshore deepwater drilling technology[J]. Natural Gas Technology, 2009, 3(6): 37-39, 79.(in Chinese) [4] 韩天旺, 蒋宏伟, 杨光. 深水双梯度钻井技术分类及其研究进展[J]. 石油矿场机械, 2019, 48(5): 83-89. (HAN Tianwang, JIANG Hongwei, YANG Guang. Classification and research progress of deepwater dual gradient drilling technology[J]. Petroleum Field Machinery, 2019, 48(5): 83-89.(in Chinese) doi: 10.3969/j.issn.1001-3482.2019.05.017 [5] SMITH K L, BHALLA K, HUEY D, et al. Concept alternatives and feasibility analyses of dual gradient drilling riser systems[C]//Offshore Technology Conference. Houston, Texas, USA, 2013. [6] 宋永杰. 深水多梯度钻井井筒压力分布特征研究[D]. 硕士学位论文. 北京: 中国石油大学(北京), 2016.SONG Yongjie. Research on wellbore pressure distribution characteristics of deep-water multi-gradient drilling[D]. Master Thesis. Beijing: China University of Petroleum (Beijing), 2016. (in Chinese) [7] 付建红, 冯剑, 陈平, 等. 深水动态压井钻井井筒压力模拟[J]. 石油学报, 2015, 36(2): 232-237. (FU Jianhong, FENG Jian, CHEN Ping, et al. Simulation on wellbore pressure during dynamic kill drilling in deep water[J]. Acta Petrolei Sinica, 2015, 36(2): 232-237.(in Chinese) doi: 10.7623/syxb201502013 [8] HERRMANN R P, SHAUGHNESSY J M. Two methods for achieving a dual gradient in deepwater[C]//SPE/IADC Drilling Conference. Amsterdam, Netherlands, 2001. [9] LOPES C A. Feasibility study on the reduction of hydrostatic pressure in a deep water riser using a gas-lift method[D]. PhD Thesis. Louisiana State University, 1997. [10] LOPES C A, BOURGOYNE JR A T. Feasibility study of a dual density mud system for deepwater drilling operations[C]//Offshore Technology Conference. Houston, Texas, USA, 1997. [11] 苏鹏, 李双贵, 李林涛, 等. 双梯度钻井隔水管中气体运移过程试验研究[J]. 石油机械, 2018, 46(1): 16-20. (SU Peng, LI Shuanggui, LI Lintao, et al. Experimental study on gas migration process in dual-gradient drilling riser[J]. China Petroleum Machinery, 2018, 46(1): 16-20.(in Chinese) [12] 殷志明, 陈国明, 许亮斌, 等. 采用双梯度钻井优化深水井井身结构[J]. 天然气工业, 2006, 26(12): 112-114. (YIN Zhiming, CHEN Guoming, XU Liangbin, et al. Optimization of casing program of deepwater well by dual-gradient drilling[J]. Natural Gas Industry, 2006, 26(12): 112-114.(in Chinese) doi: 10.3321/j.issn:1000-0976.2006.12.030 [13] 殷志明. 新型深水双梯度钻井系统原理、方法及应用研究[D]. 博士学位论文. 青岛: 中国石油大学, 2007.YIN Zhiming. Research on the principle, method and application of a new type of deep-water dual-gradient drilling system[D]. PhD Thesis. Qingdao: China University of Petroleum, 2007. (in Chinese) [14] 马永乾, 孙宝江, 邵茹, 等. 注气法双梯度钻井隔水管环空温度场模拟[J]. 石油学报, 2014, 35(4): 779-785. (MA Yongqian, SUN Baojiang, SHAO Ru, et al. Simulation computation of temperature field in riser annulus for dual-gradient drilling using gas injection[J]. Acta Petrolei Sinica, 2014, 35(4): 779-785.(in Chinese) doi: 10.7623/syxb201404022 [15] 杨小刚. 双梯度钻井井控中的多相流动计算[D]. 硕士学位论文. 青岛: 中国石油大学, 2009.YANG Xiaogang. Multiphase flow calculation in double gradient drilling well control[D]. Master Thesis. Qingdao: China University of Petroleum, 2009. (in Chinese) [16] 黄伟, 郝俊芳. 压井动态过程的理论分析及模拟计算[J]. 石油学报, 1994, 15(2): 147-154. (HUANG Wei, HAO Junfang. Theoretical analysis and simulated calculation of dynamic well control[J]. Acta Petrolei Sinica, 1994, 15(2): 147-154.(in Chinese) doi: 10.3321/j.issn:0253-2697.1994.02.013 [17] 苗典远. 隔水管气举双梯度钻井注气量计算及其影响因素分析[J]. 石油钻探技术, 2013, 41(2): 23-27. (MIAO Dianyuan. Calculation of gas injection rate and affecting factors of gaslift dual gradient drilling with riser[J]. Petroleum Drilling Technology, 2013, 41(2): 23-27.(in Chinese) doi: 10.3969/j.issn.1001-0890.2013.02.005 [18] STANISLAWEK M, SMITH J R. Analysis of alternative well-control methods for dual-density deepwater drilling[C]//IADC/SPE Drilling Conference. Miami, Florida, USA, 2006. [19] 甘火华. 深水隔水管气举钻井与热力学耦合的压降模型研究[D]. 硕士学位论文. 北京: 中国石油大学(北京), 2010.GAN Huohua. Research on the pressure drop model of deep-water riser gas lift drilling and thermodynamic coupling[D]. Master Thesis. Beijing: China University of Petroleum (Beijing), 2010. (in Chinese) [20] MAO L, LIU Q, NIE K, et al. Temperature prediction model of gas wells for deep-water production in South China Sea[J]. Journal of Natural Gas Science and Engineering, 2016, 36: 708-718. doi: 10.1016/j.jngse.2016.11.015 [21] 杨宏伟, 李军, 柳贡慧, 等. 深水多梯度钻井井筒温度场[J]. 中国石油大学学报(自然科学版), 2020, 44(5): 62-69. (YANG Hongwei, LI Jun, LIU Gonghui, et al. Wellbore temperature profiling for deepwater multi-gradient drilling[J]. Journal of China University of Petroleum (Edition of Natural Science) , 2020, 44(5): 62-69.(in Chinese) [22] 高永海, 孙宝江, 王志远, 等. 深水钻探井筒温度场的计算与分析[J]. 中国石油大学学报(自然科学版), 2008, 32(2): 58-62. (GAO Yonghai, SUN Baojiang, WANG Zhiyuan, et al. Calculation and analysis of wellbore temperature field in deepwater drilling[J]. Journal of China University of Petroleum (Edition of Natural Sciences) , 2008, 32(2): 58-62.(in Chinese) [23] DZIUBINSKI M, FIDOS H, SOSNO M. The flow pattern map of a two-phase non-Newtonian liquid-gas flow in the vertical pipe[J]. International Journal of Multiphase Flow, 2004, 30(6): 551-563. [24] KAREN B. Analysis of alternative well-control methods for dual-density deepwater drilling[J]. Journal of Petroleum Technology, 2007, 59(1): 61-63. doi: 10.2118/0107-0061-JPT -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号