Ultralow Friction Whipping Effects of Sandstone Blocks Based on FLAC-3D

-

摘要:

随着矿山开采深度的持续增加,深部岩体力学行为呈现出新形式、新特征。广泛应用于建筑行业的鞭梢效应与深部岩体部分动力响应现象极为相似。故从结构特征出发,以砂岩块体为研究对象,工作块体(水平冲击作用块体)水平位移及加速度为参考指标,通过试验及FLAC-3D数值模拟计算的方式,探究工作块体“位置”及“尺寸”对其超低摩擦鞭梢效应影响机制。研究表明:系统产生超低摩擦鞭梢效应的难易程度与工作块体尺寸密切相关,模拟中工作块体边长为标准块体(边长100 mm立方体)边长2/5时,系统结构诱发超低摩擦鞭梢效应尤其显著;在一定范围内,工作块体所处位置距扰动源越远,超低摩擦鞭梢效应强度越大,当超过这一范围时,则会出现减小趋势,即超低摩擦鞭梢效应强度随工作块体与震源块体间距离呈先增后减关系。

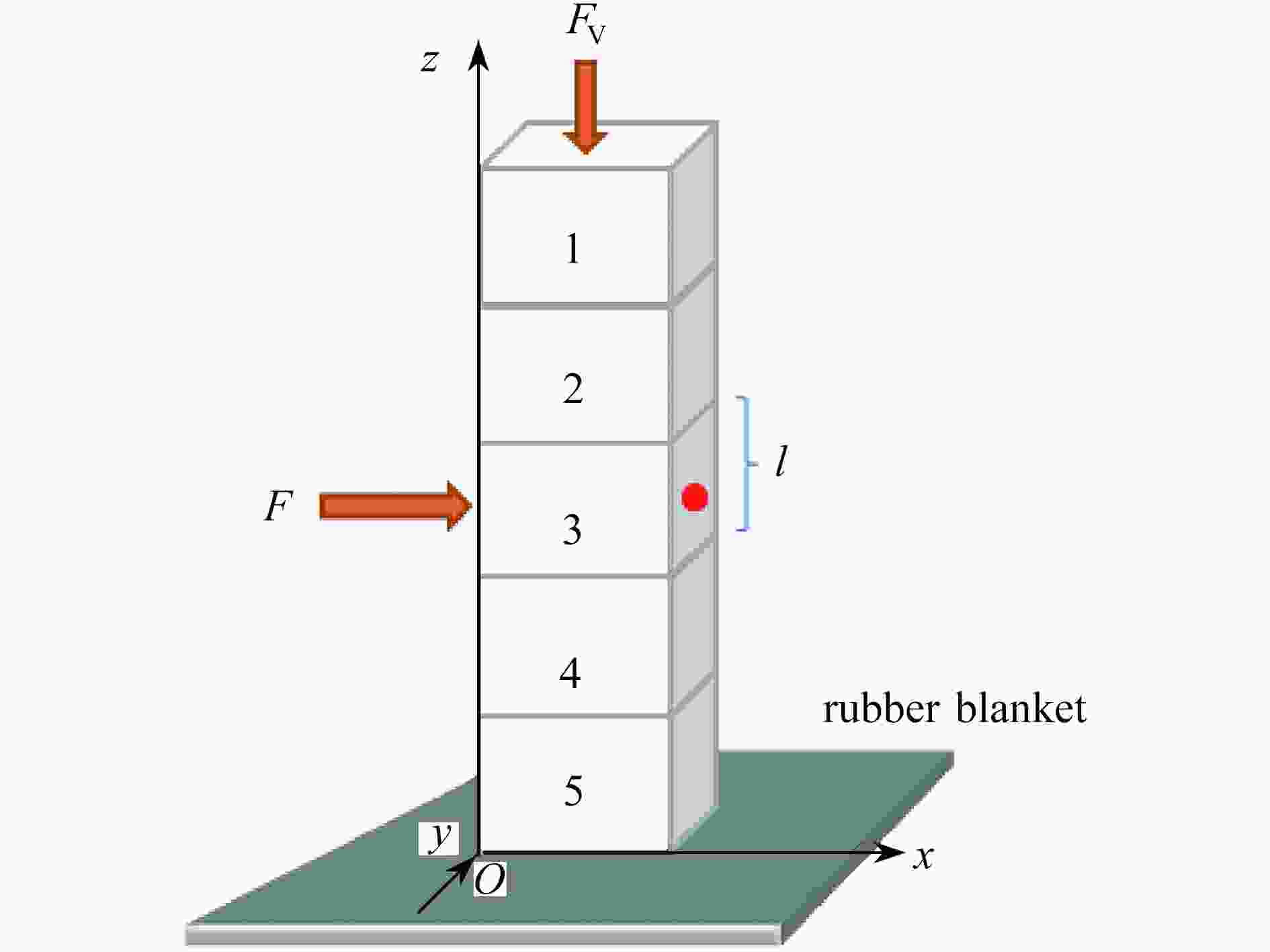

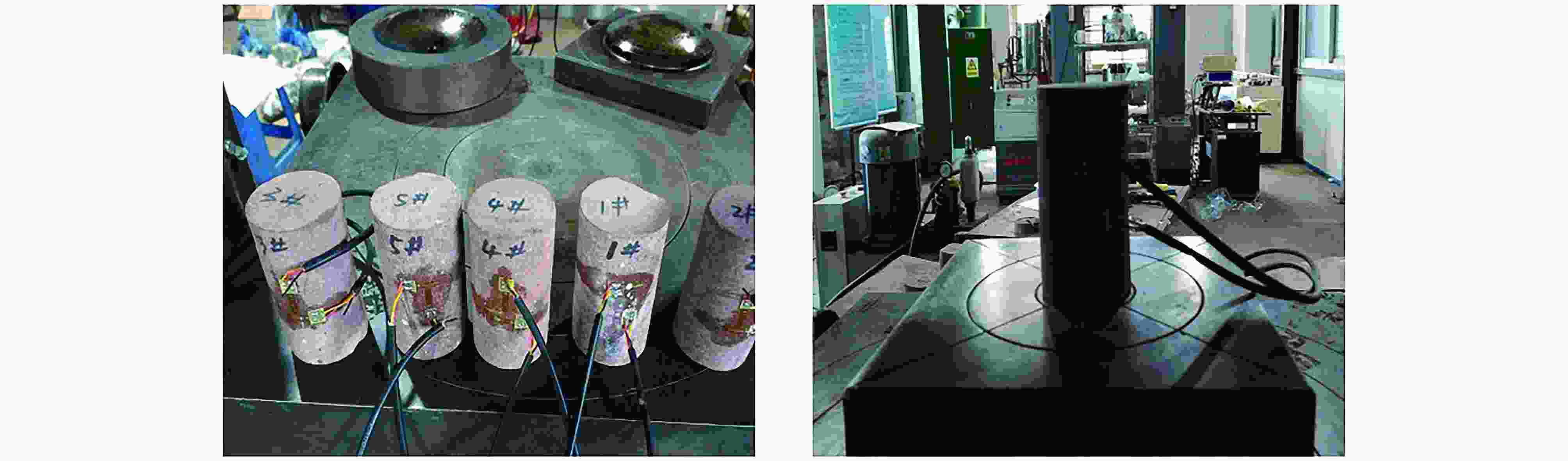

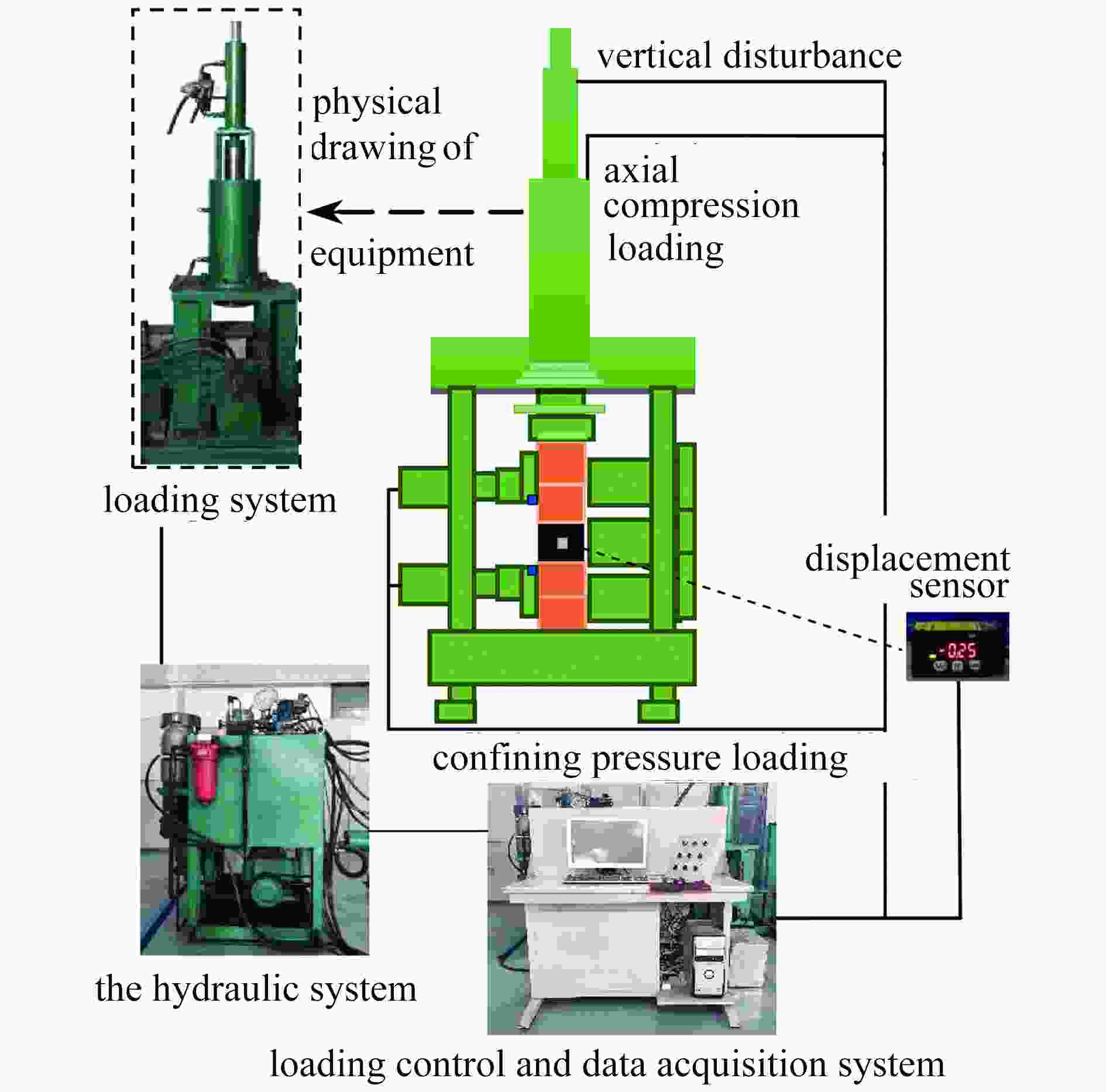

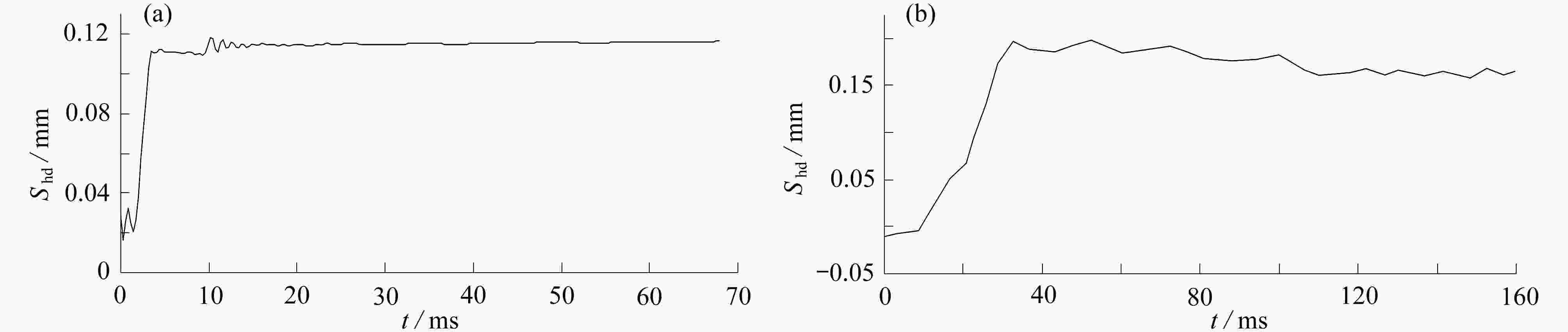

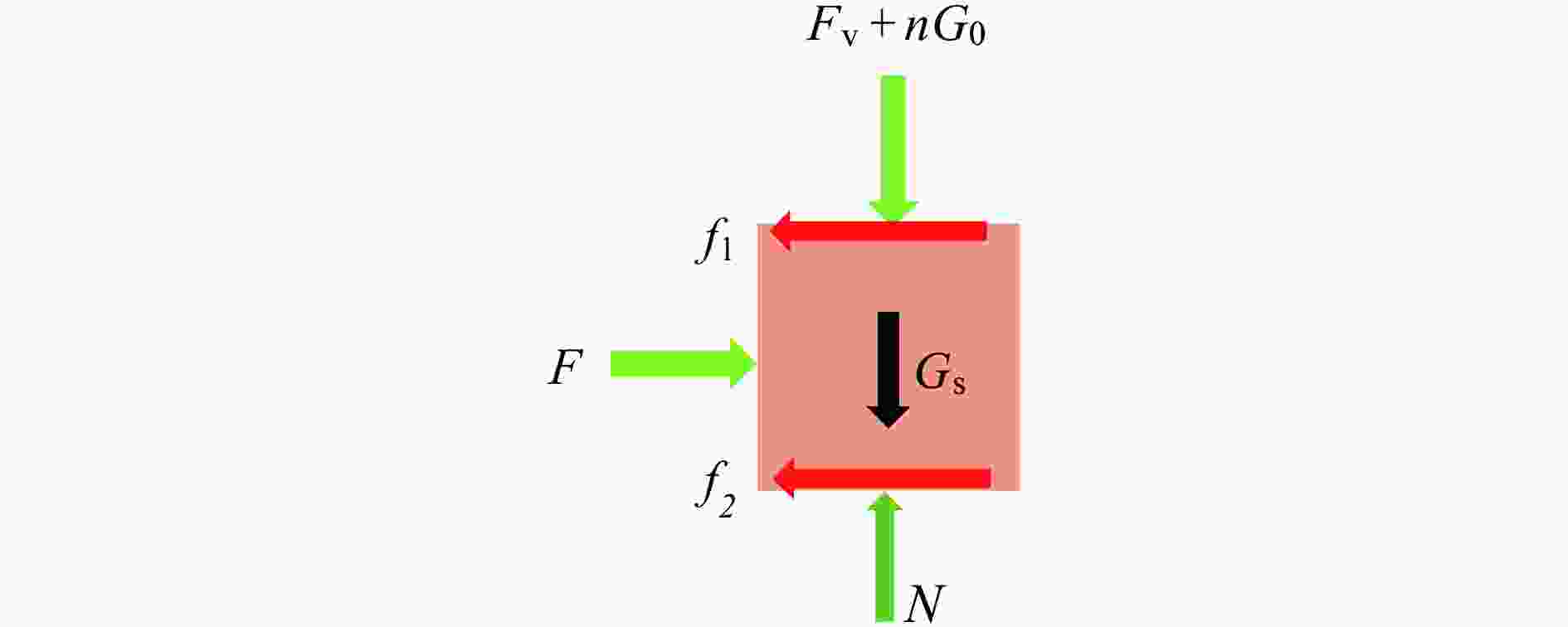

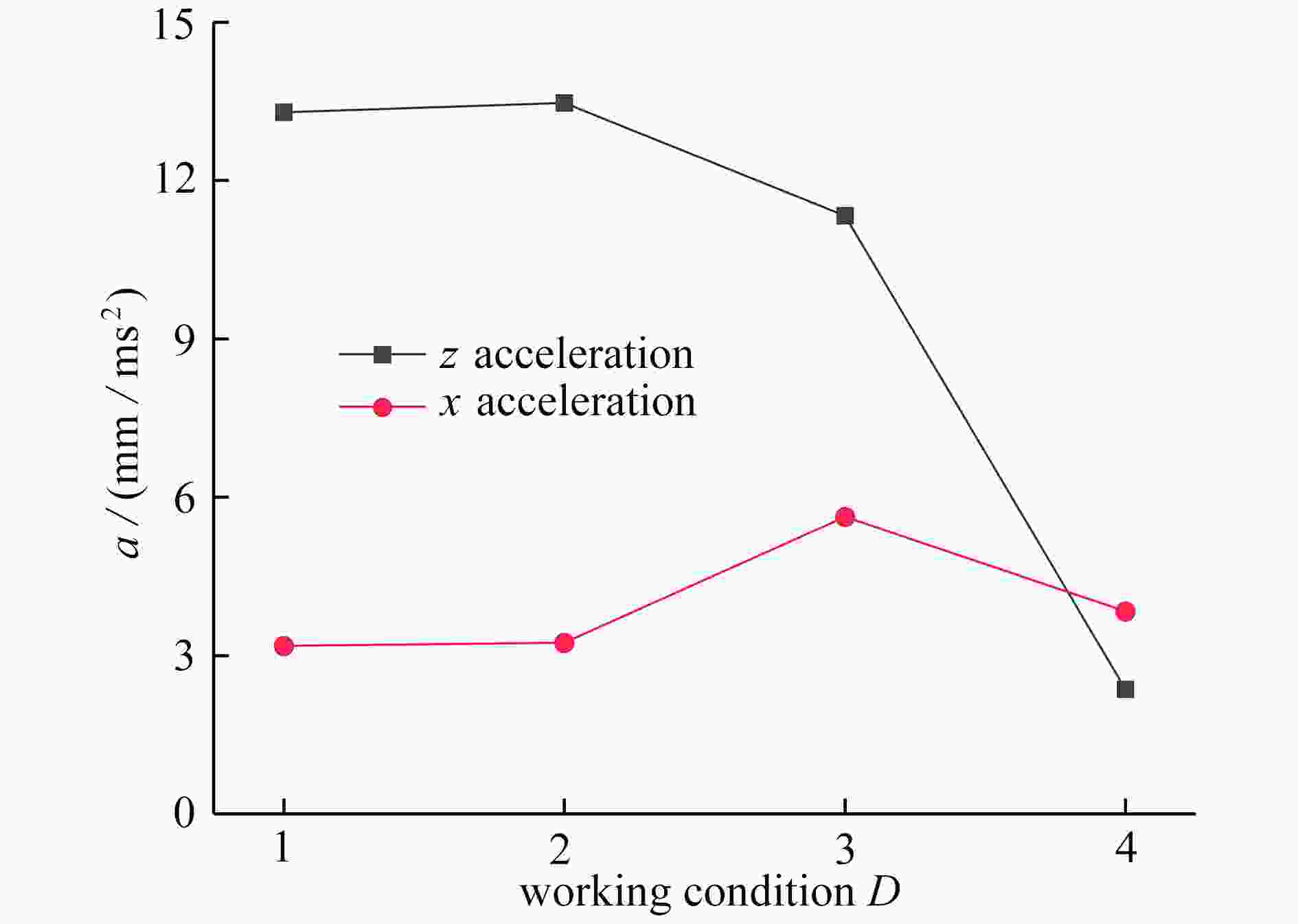

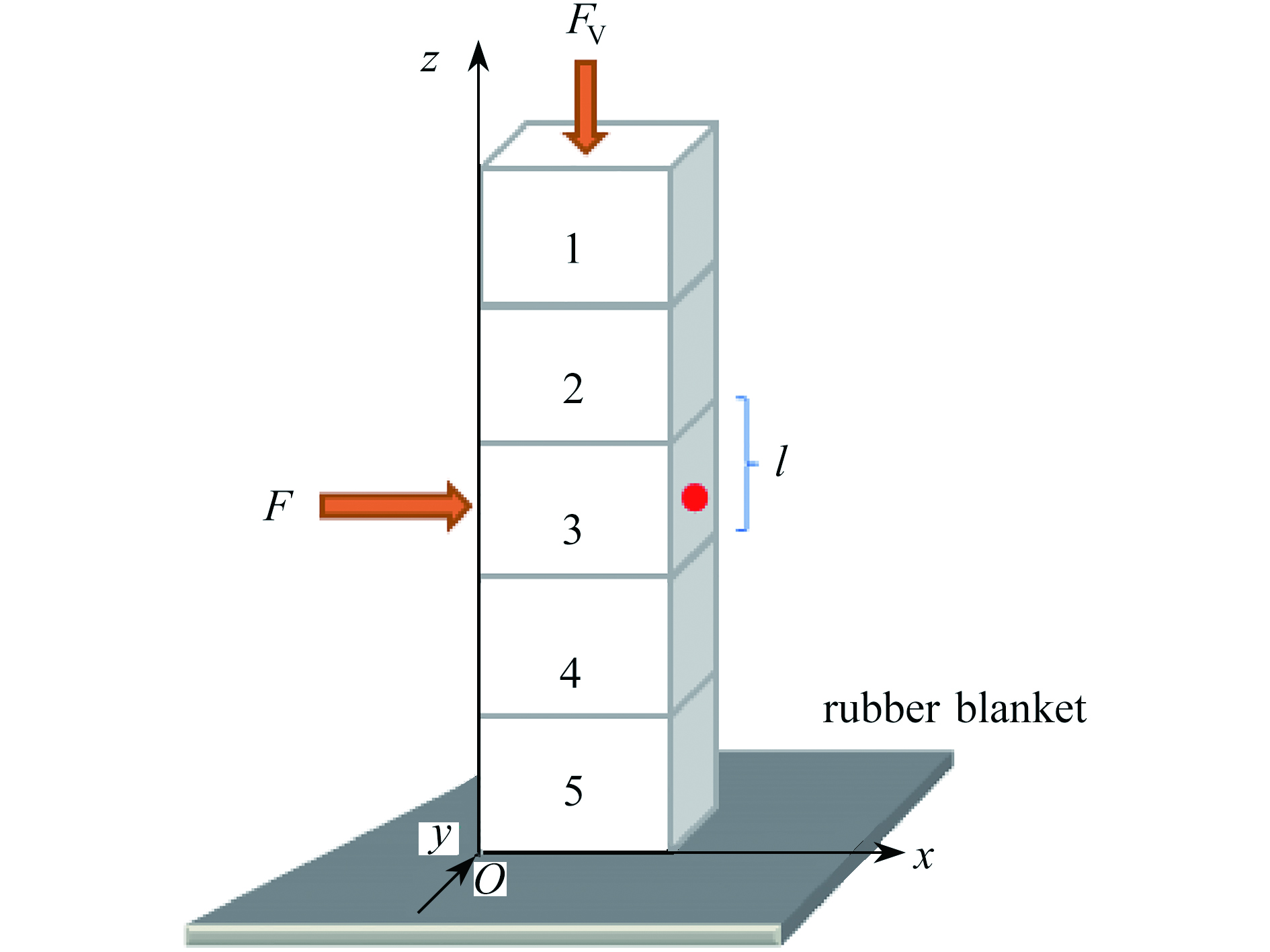

Abstract:With the continual increase of mining depths, the mechanical behaviors of deep rock masses present new forms and new characteristics. The whipping effect widely used in the construction industry is very similar to the partial dynamic responses of deep rock masses. Based on the structural characteristics, with the sandstone blocks as the research object, and the horizontal displacement and acceleration of the working block (horizontally impacted block) as the reference indicators, by experiments and through FLAC-3D numerical simulations, the influential mechanisms of the working block positions and sizes on the ultralow friction whipping effects were investigated. The work shows that, the intensity of the system’s ultralow friction whipping effect is closely related to the size of the working block. In the simulation, when the side length of the working block is 2/5 of that of the standard block (with a cube side length of 100 mm), the system structure will induce particularly severe ultralow friction whipping effects; within a certain range, the farther the working block position is from the disturbance source, the greater the intensity of the ultralow friction whipping effect will be. Beyond this range, a decreasing trend will occur, that is, the ultralow friction whipping effect intensity will increase first and then decrease with the distance between the working block and the source block.

-

Key words:

- stress wave disturbance /

- sandstone block /

- rock burst /

- FLAC-3D /

- ultralow friction whipping effect

-

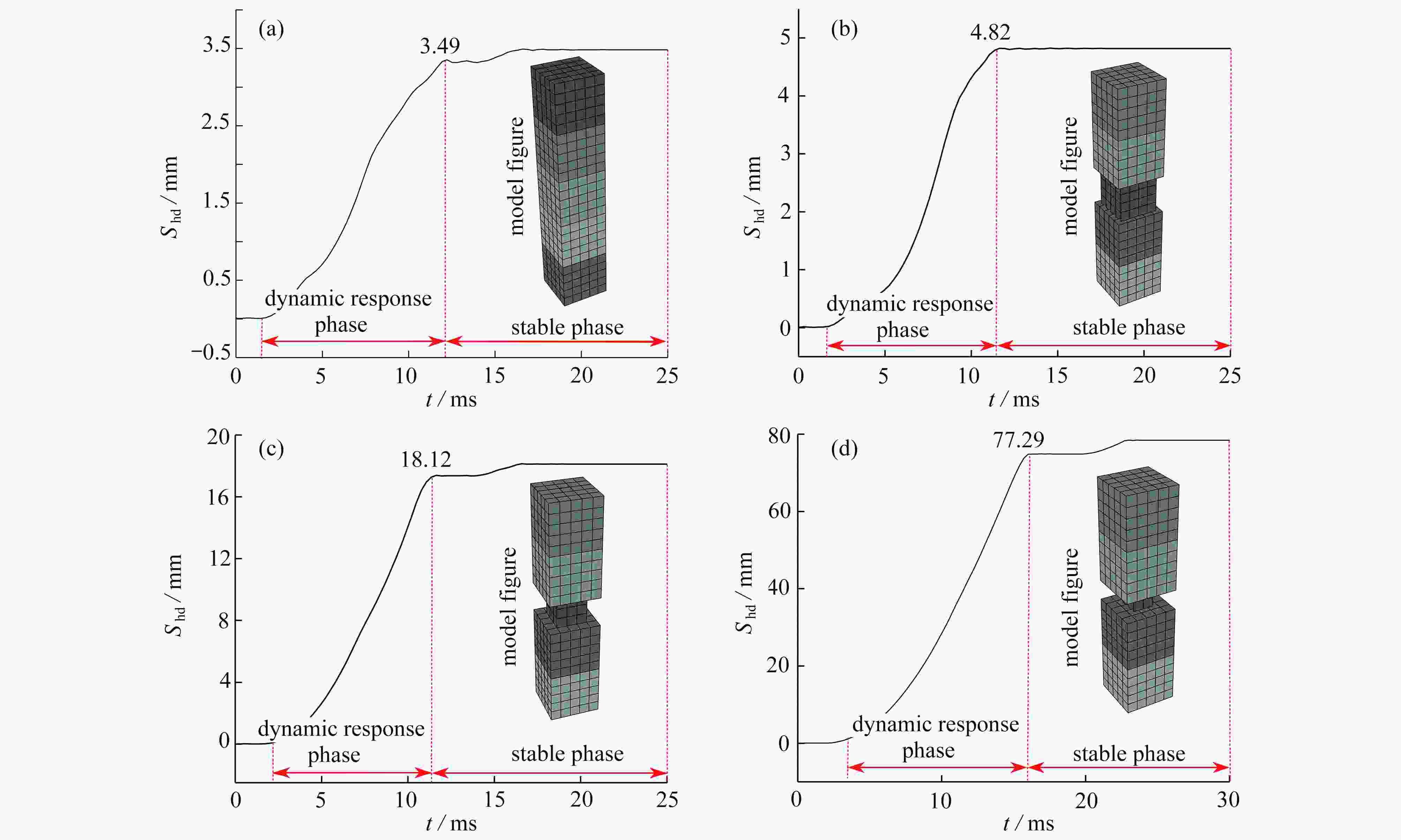

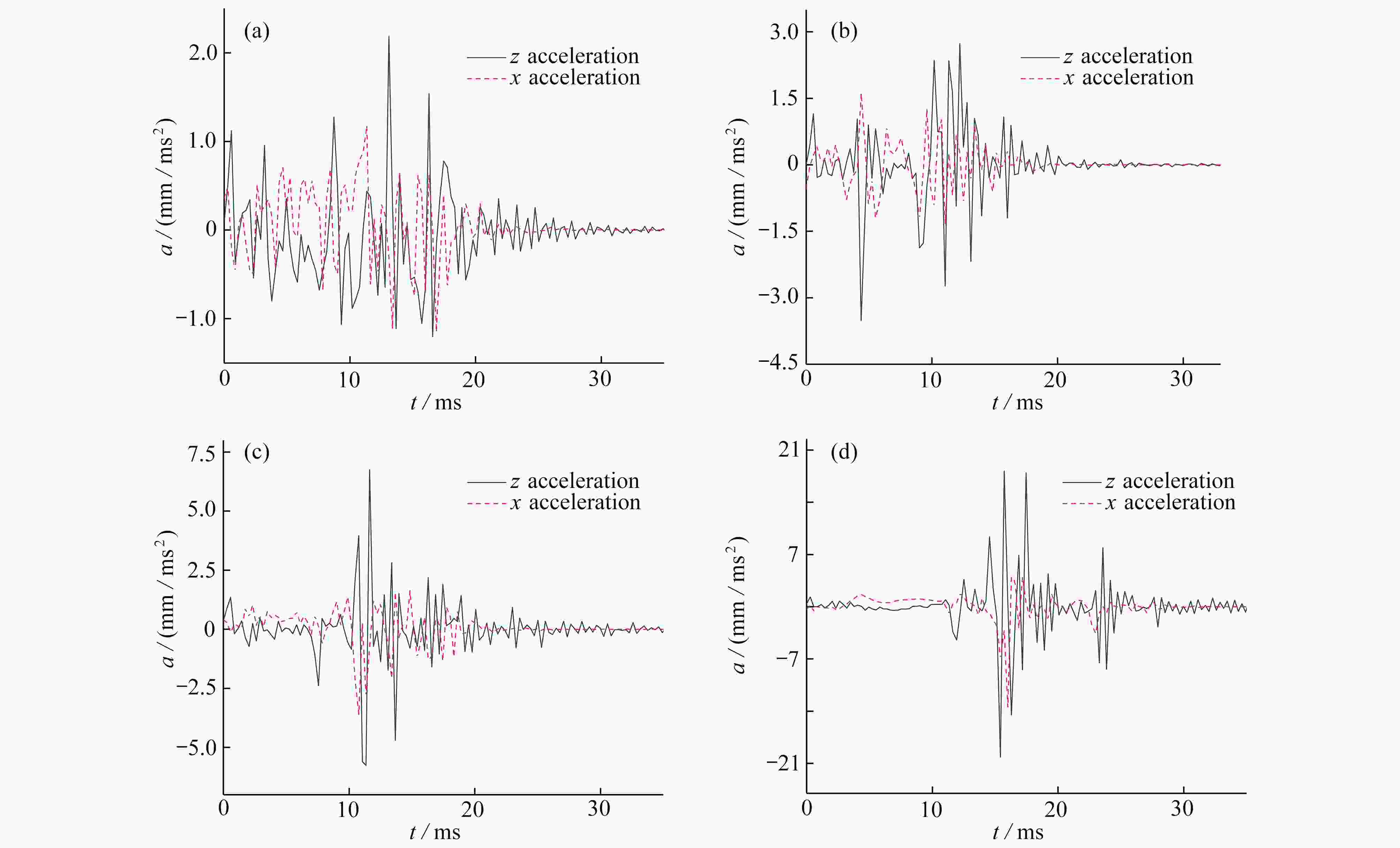

7 不同尺寸工作块体水平位移时程曲线:(a) 边长100 mm立方体试件;(b) 边长80 mm立方体试件;(c) 边长60 mm立方体试件;(d) 边长40 mm立方体试件;(e) 边长20 mm立方体试件

7. Time history curves of horizontal displacements of working blocks with different sizes: (a) the cubic specimen with a side length of 100 mm; (b) the cubic specimen with a side length of 80 mm; (c) the cubic specimen with a side length of 60 mm; (d) the cubic specimen with a side length of 40 mm; (e) the cubic specimen with a side length of 20 mm

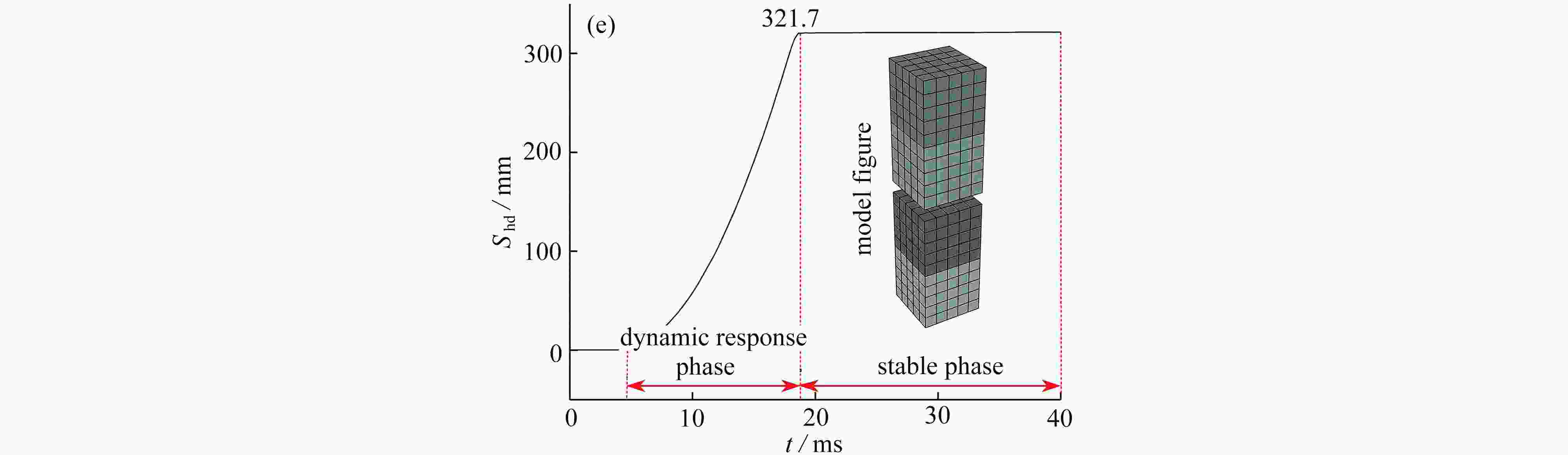

8 工作块体加速度幅值变化曲线:(a) 边长100 mm立方体试件;(b) 边长80 mm立方体试件;(c) 边长60 mm立方体试件;(d) 边长40 mm立方体试件;(e) 边长20 mm立方体试件

8. Change curves of acceleration amplitudes of working blocks: (a) the cubic specimen with a side length of 100 mm; (b) the cubic specimen with a side length of 80 mm; (c) the cubic specimen with a side length of 60 mm; (d) the cubic specimen with a side length of 40 mm; (e) the cubic specimen with a side length of 20 mm

表 1 砂岩块体力学参数

Table 1. Physical parameters of sandstone blocks

parameter value ρ/(kg/m3) 2750 Rm/MPa 0.77 C /MPa 2.2 ϕ/(°) 30 E/GPa 5.39 υ 0.239 表 2 砂岩块体间接触面力学参数

Table 2. Mechanical parameters of contact surfaces between sandstone blocks

parameter value Rm /MPa 0.039 C /MPa 0.11 ϕ/(°) 15 kn/(GPa/m) 6342 ks/(GPa/m) 6342 -

[1] 宋蕾. 试析国内煤炭开采现状及发展[J]. 现代经济信息, 2019, 18: 356. (SONG Lei. The present situation and development of domestic coal mining are analyzed[J]. Modern Economic Information, 2019, 18: 356.(in Chinese) doi: 10.3969/j.issn.1001-828X.2019.06.303 [2] 钱七虎. 非线性岩石力学的新进展: 深部岩体力学的若干关键问题[C]//中国岩石力学与工程学会. 第八次全国岩石力学与工程学术大会论文集. 北京: 科学出版社, 2004: 10-17.QIAN Qihu. New progress in nonlinear rock mechanics: some key problems in deep rock mechanics[C]//Chinese Society for Rock Mechanics & Engineering. Proceedings of the 8th National Conference on Rock Mechanics and Engineering. Beijing: Science Press, 2004: 10-17. (in Chinese) [3] 谢和平, 高峰, 鞠杨, 等. 深部开采的定量界定与分析[J]. 煤炭学报, 2015, 40(1): 1-10. (XIE Heping, GAO Feng, JU Yang. et al. Quantitative definition and investigation of deep mining[J]. Journal of China Coal Society, 2015, 40(1): 1-10.(in Chinese) [4] KURLENYA M V, ADUSHKIN V V, OPARIN V N. Alternating reaction of rocks to dynamic action[J]. Dokl an SSSR, 1992, 26(2): 323-327. [5] KURLENYA M V, OPARIN V N, VOSTRIKOV V I. Effect of anomalously low friction in block media[J]. Journal of Applied Mechanicals and Technical Physics, 1999, 40(6): 1116-1120. doi: 10.1007/BF02469182 [6] KURLENYA M V, OPARIN V N, BALMASHNOVA E G, et al. On dynamic behavior of “self-stressed” block media, part Ⅰ: one dimensional mechanico-mathematical model[J]. Journal of Mining Science, 2001, 37(1): 1-9. doi: 10.1023/A:1016792400026 [7] 王明洋, 周泽平, 钱七虎. 深部岩体的构造和变形与破坏问题[J]. 岩石力学与工程学报, 2006, 25(3): 448-455. (WANG Mingyang, ZHOU Zeping, QIAN Qihu. Tectonic, deformation and failure problems of deep rock mass[J]. Chinese Journal of Rock Mechanics and Engineering, 2006, 25(3): 448-455.(in Chinese) doi: 10.3321/j.issn:1000-6915.2006.03.002 [8] 王明洋, 戚承志, 钱七虎. 深部岩体块系介质变形与运动特性研究[J]. 岩石力学与工程学报, 2005, 24(16): 2825-2830. (WANG Mingyang, QI Chengzhi, QIAN Qihu. Study on deformation and motion characteristics of blocks in deep rock mass[J]. Chinese Journal of Rock Mechanics and Engineering, 2005, 24(16): 2825-2830.(in Chinese) doi: 10.3321/j.issn:1000-6915.2005.16.003 [9] 吴昊, 方秦, 张亚栋, 等. 一维块系地质块体波动特性的试验和理论研究[J]. 岩土工程学报, 2010, 32(4): 600-611. (WU Hao, FANG Qin, ZHANG Yadong, et al. Propagation properties of stress waves in one-dimensional geo-block medium[J]. Chinese Journal of Rock Mechanics and Engineering, 2010, 32(4): 600-611.(in Chinese) [10] 吴昊, 方秦, 王洪亮. 深部块系岩体超低摩擦现象的机理分析[J]. 岩土工程学报, 2008, 30(5): 769-775. (WU Hao, FANG Qin, WANG Hongliang. Mechanism of anomalously low friction phenomenon in deep block rock mass[J]. Chinese Journal of Geotechnical Engineering, 2008, 30(5): 769-775.(in Chinese) doi: 10.3321/j.issn:1000-4548.2008.05.025 [11] 何满潮, 王炀, 刘冬桥, 等. 基于二维数字图像相关技术的块系花岗岩超低摩擦效应实验研究[J]. 煤炭学报, 2018, 43(10): 2732-2740. (HE Manchao, WANG Yang, LIU Dongqiao, et al. Experimental study on ultra-low friction effect of granite block based on two-dimensional digital image correlation technique[J]. Journal of China Coal Society, 2018, 43(10): 2732-2740.(in Chinese) [12] 王德荣, 陆渝生, 冯淑芳, 等. 深部岩体动态特性多功能试验系统的研制[J]. 岩石力学与工程学报, 2008, 27(3): 601-606. (WANG Derong, LU Yusheng, FENG Shufang, et al. Development of multipurpose test system for dynamic behaviors of deep rock masses[J]. Chinese Journal of Rock Mechanics and Engineering, 2008, 27(3): 601-606.(in Chinese) doi: 10.3321/j.issn:1000-6915.2008.03.022 [13] 李利萍, 李卫军, 潘一山. 冲击扰动对超低摩擦型冲击地压影响分析[J]. 岩石力学与工程学报, 2019, 38(1): 111-120. (LI Liping, LI Weijun, PAN Yishan. Influence of impact disturbance on anomalously low friction rock bursts[J]. Chinese Journal of Rock Mechanics and Engineering, 2019, 38(1): 111-120.(in Chinese) [14] 李利萍, 吴金鹏, 鞠翔宇, 等. 围压与冲击扰动作用下组合煤岩超低摩擦效应分析[J]. 地质力学学报, 2019, 25(6): 1099-1106. (LI Liping, WU Jinpeng, JU Xiangyu, et al. Analysis of ultra-low friction effect of coal-rock combination block under confining pressure and impact disturbance[J]. Journal of Geomechanics, 2019, 25(6): 1099-1106.(in Chinese) doi: 10.12090/j.issn.1006-6616.2019.25.06.093 [15] 唐红梅, 周福川, 陈松, 等. 高烈度下双裂缝主控结构面危岩的断裂破坏机制分析[J]. 应用数学和力学, 2021, 42(6): 645-655. (TANG Hongmei, ZHOU Fuchuan, CHEN Song, et al. Fracture mechanism of unstable rock with double-crack control discontinuity subjected to high earthquake intensities[J]. Applied Mathematics and Mechanics, 2021, 42(6): 645-655.(in Chinese) [16] 钟万勰, 林家浩. 高层建筑振动的“鞭梢效应”[J]. 振动与冲击, 1985(2): 1-6. (ZHONG Wanxie, LING Jiahao. “Whiplash effect” of high buildings caused by earthquakes[J]. Journal of Vibration and Shock, 1985(2): 1-6.(in Chinese) [17] 李桂青, 熊火清. 结构鞭梢效应的控制与分析[J]. 地震工程与工程振动, 1987, 7(4): 1-14. (LI Guiqing, XIONG Huoqing. Control and analysis of structural whiplash effect[J]. Earthquake Engineering and Engineering Vibration, 1987, 7(4): 1-14.(in Chinese) [18] 杨佑发, 袁政强, 敬登虎. 高层建筑结构抗震设计中鞭梢效应的分析[J]. 世界地震工程, 2004, 20(1): 85-89. (YANG Youfa, YUAN Zhengqiang, JING Denghu. Analysis of whipping effect on seismic design of tall building[J]. World Earthquake Engineering, 2004, 20(1): 85-89.(in Chinese) doi: 10.3969/j.issn.1007-6069.2004.01.013 [19] 季金铭, 高文学, 曹晓立, 等. 高陡边坡动力响应研究[J]. 爆破, 2020, 37(2): 1-7. (JI Jinming, GAO Wenxue, CAO Xiaoli, et al. Study on dynamic stability of high and steep slopes[J]. Blasting, 2020, 37(2): 1-7.(in Chinese) doi: 10.3963/j.issn.1001-487X.2020.02.001 [20] 郜宁静, 陶桂兰, 童峣, 等. 地震作用下超高扬程升船机塔柱结构的鞭梢效应[J]. 水电能源科学, 2020, 38(4): 104-107. (GAO Ningjing, TAO Guilan, TONG Yao, et al. Whipping effect of large vertical ship-lift tower structure under seismic action[J]. Water Resources and Power, 2020, 38(4): 104-107.(in Chinese) [21] 陈育民, 徐鼎平. FLAC/FLAC 3D基础与工程实例[M]. 2版. 北京: 中国水利水电出版社, 2013: 143-144.CHEN Yumin, XU Dingping. FLAC/FLAC 3D Foundation and Engineering Examples[M]. 2nd ed. Beijing: China Water & Power Press, 2013: 143-144. (in Chinese) -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号