Prediction of Concrete Meso-Model Stress-Strain Curves Based on GoogLeNet

-

摘要:

非均质复合材料的宏观力学性能往往取决于细观组分的分布方式和力学性能,但是建立明确的关系表达式极其困难。为了应对这一挑战,以混凝土为研究对象,提出了一种基于深度学习的策略,能够高效、准确地通过细观模型图像信息获取应力-应变曲线。首先,使用基于卷积神经网络(convolutional neural network,CNN)的GoogLeNet模型进行图像信息识别和提取,并针对应力-应变曲线的复杂性特点,进行了数据预处理操作,并且设计了相应的多任务损失函数。数据集中的细观模型图像采用基于Monte-Carlo的随机骨料模型生成,并且使用数值模拟试验获取对应细观模型的单轴压缩应力-应变曲线。最后,通过对神经网络的训练和测试评估了所提出方法的可行性。结果表明,GoogLeNet模型训练效率和预测精度均优于AlexNet和ResNet模型,具有良好的泛化能力和鲁棒性。

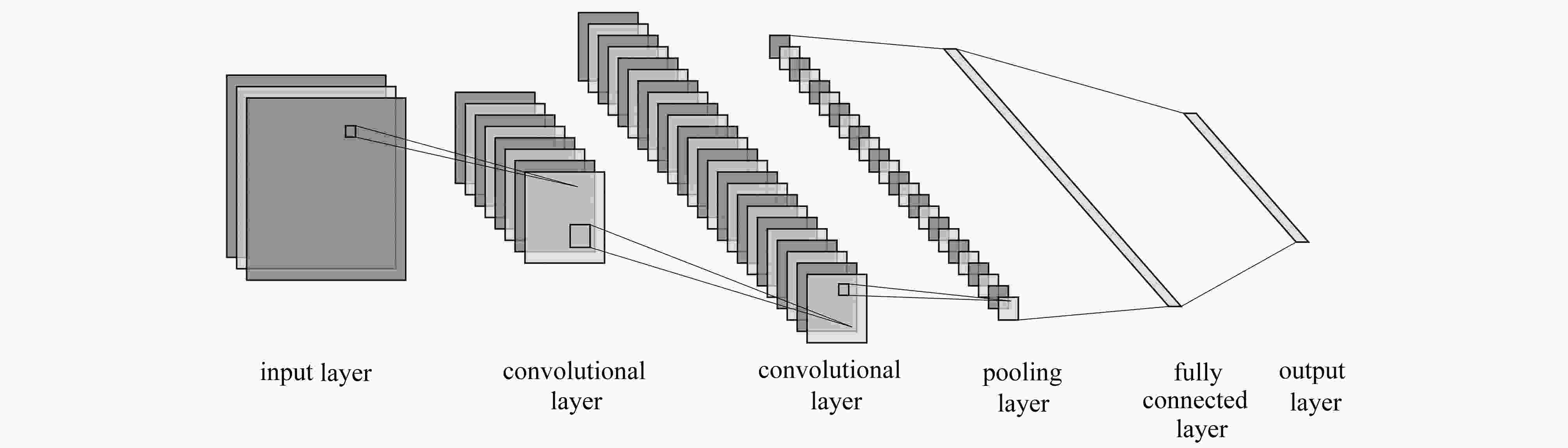

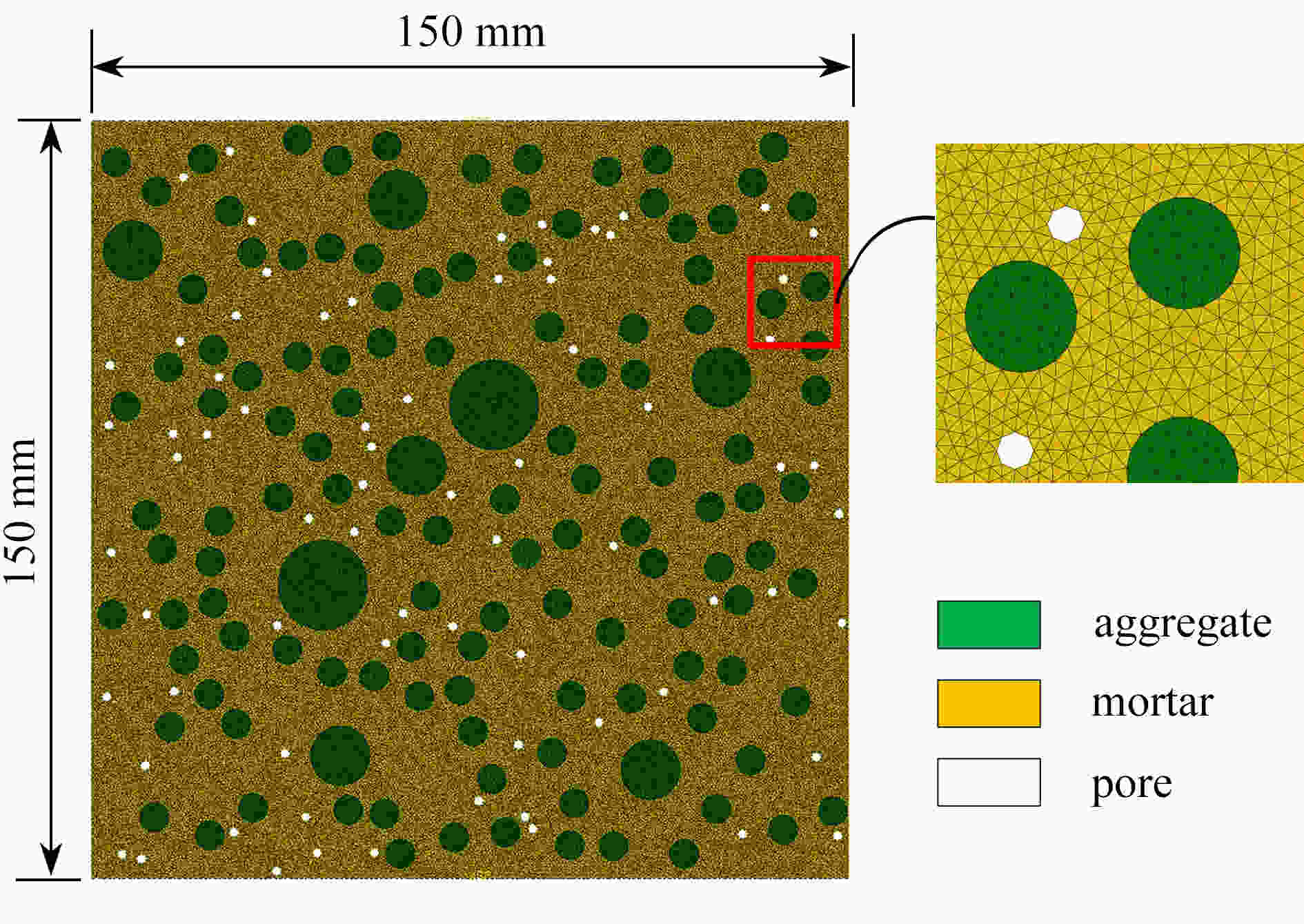

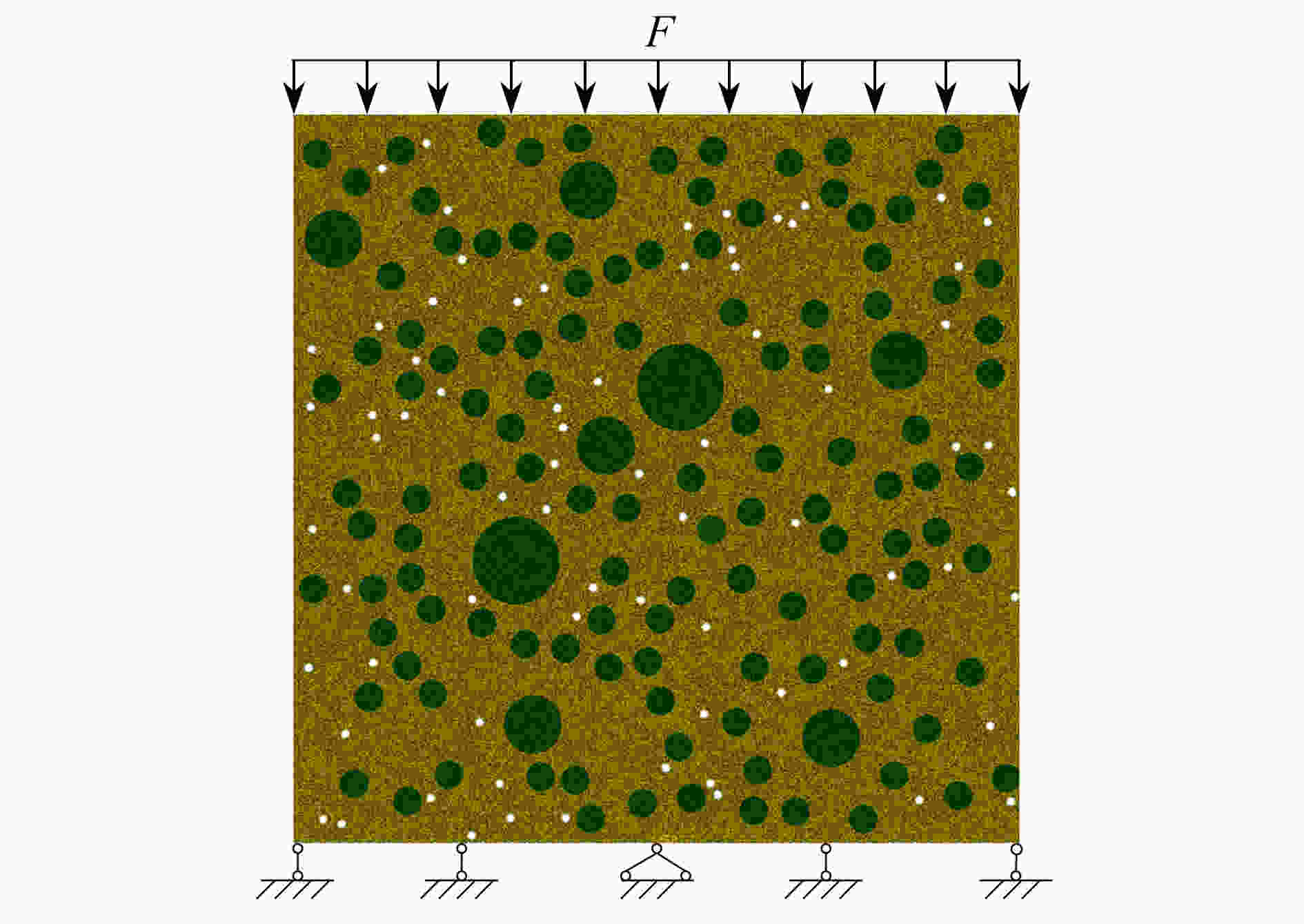

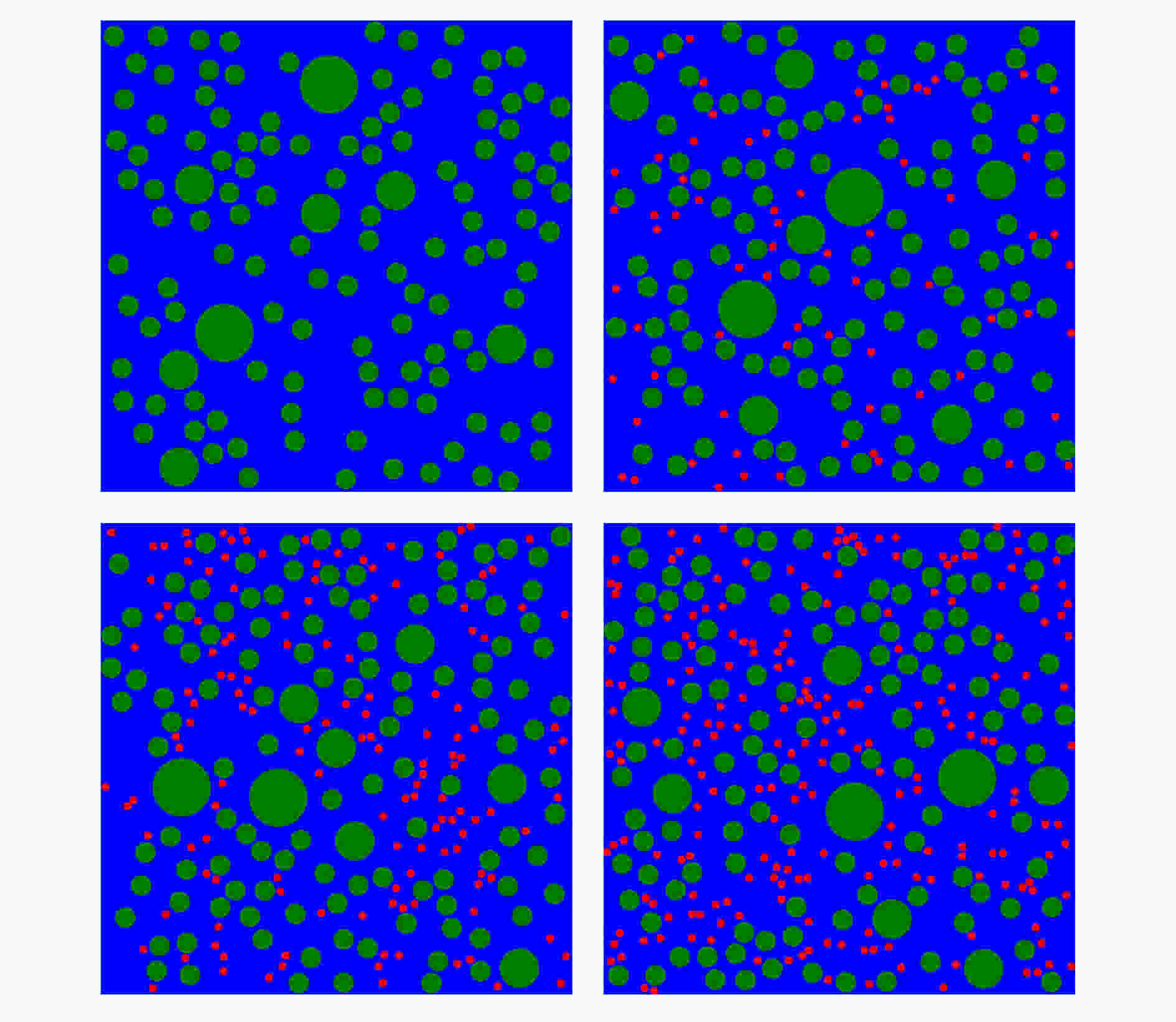

Abstract:Generally, the macro-scopic mechanical properties of heterogeneous composites depend on meso-components’ distribution and mechanical properties, but it is extremely difficult to establish a clear macro-meso relationship expression. To cope with this challenge, for concrete, a strategy based on deep learning was proposed to obtain the stress-strain curves through meso-model image information. First, the GoogLeNet model based on convolutional neural networks was used for image information recognition and extraction. According to the complexity of the stress-strain curve, data preprocessing operations were performed and the corresponding multi-task loss function was designed. The meso-model images in the data set were generated with the random aggregate model based on the Monte Carlo method, and numerical simulation experiments were conducted to obtain the uniaxial compressive stress-strain curve of the corresponding meso-model. Finally, the feasibility of the proposed method was evaluated through training and testing. The training efficiency and prediction accuracy of the GoogLeNet model are better than the AlexNet and ResNet models, and have good generalization ability and robustness.

-

Key words:

- concrete /

- meso-model /

- GoogLeNet /

- convolutional neural network /

- stress-strain curve

-

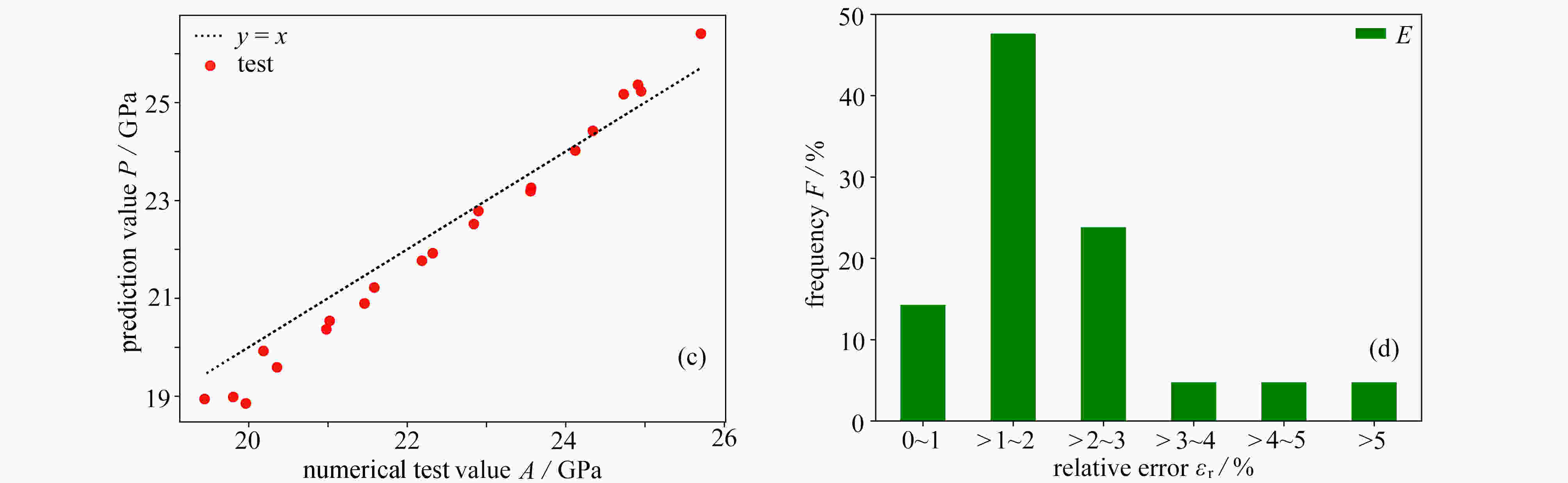

图 9 部分测试集的预测结果和数值计算结果对比:(a) 骨料体积分数39%,孔隙率1%;(b) 骨料体积分数39%,孔隙率6%;(c) 骨料体积分数39%,孔隙率9%;(d) 骨料体积分数40%,孔隙率1%;(e) 骨料体积分数40%,孔隙率3%;(f) 骨料体积分数40%,孔隙率8%

Figure 9. Comparison of prediction results with numerical test data: (a) aggregate volume fraction at 39%, porosity at 1%; (b) aggregate volume fraction at 39%, porosity at 6%; (c) aggregate volume fraction at 39%, porosity at 9%; (d) aggregate volume fraction at 40%, porosity at 1%; (e) aggregate volume fraction at 40%, porosity at 3%; (f) aggregate volume fraction at 40%, porosity at 8%

表 1 细观组分的力学参数

Table 1. Mechanical parameters of meso-compositions

item Poisson’s ratio υ Young’s modulus E / GPa compressive strength fc / MPa tensile strength ft / MPa aggregate 0.23 43 − − mortar 0.2 25 35 3.5 表 2 各卷积神经网络模型的对比

Table 2. Comparison of CNN models

CNN epoch number of layers model size validation

losstime GoogLeNet 100 22 23.1 MB 1.016 2308.0 s AlexNet 100 8 223 MB 6.139 3826.2 s ResNet50 100 50 90.6 MB 1.773 6263.8 s -

[1] 肖诗云, 乔倩倩. 混凝土等效弹性模量细观影响因素[J]. 沈阳建筑大学学报(自然科学版), 2015, 31(4): 636-643. (XIAO Shiyun, QIAO Qianqian. Mesoscopic influence factor analysis on the equivalent elastic modulus of concrete[J]. Journal of Shenyang Jianzhu University (Natural Science) , 2015, 31(4): 636-643.(in Chinese) [2] 杜敏, 金浏, 李东, 等. 骨料粒径对混凝土劈拉性能及尺寸效应影响的细观数值研究[J]. 工程力学, 2017, 34(9): 54-63. (DU Min, JIN Liu, LI Dong, et al. Mesoscopic simulation study of the influence of aggregate size on mechanical properties and specimen size effect of concrete subjected to splitting tensile loading[J]. Engineering Mechanics, 2017, 34(9): 54-63.(in Chinese) doi: 10.6052/j.issn.1000-4750.2016.02.0122 [3] 张伟平, 王浩, 顾祥林. 粗骨料随机分布对混凝土导热性能的影响[J]. 建筑材料学报, 2017, 20(2): 168-173,197. (ZHANG Weiping, WANG Hao, GU Xianglin. Effects of randomly distributed aggregates on thermal properties of concrete[J]. Journal of Building Materials, 2017, 20(2): 168-173,197.(in Chinese) doi: 10.3969/j.issn.1007-9629.2017.02.002 [4] ZHANG J, WANG Z Y, YANG H W, et al. 3D meso-scale modeling of reinforcement concrete with high volume fraction of randomly distributed aggregates[J]. Construction and Building Materials, 2018, 164: 350-361. doi: 10.1016/j.conbuildmat.2017.12.229 [5] HINTON G E, SALAKHUTDINOV R R. Reducing the dimensionality of data with neural networks[J]. Science, 2006, 313(5786): 504-507. doi: 10.1126/science.1127647 [6] YANN L C, YOSHUA B, GEOFFREY H. Deep learning[J]. Nature, 2015, 521: 436-444. doi: 10.1038/nature14539 [7] 严春满, 王铖. 卷积神经网络模型发展及应用[J]. 计算机科学与探索, 2021, 15(1): 27-46. (YAN Chunman, WANG Cheng. Development and application of convolutional neural network model[J]. Journal of Frontiers of Computer Science & Technology, 2021, 15(1): 27-46.(in Chinese) doi: 10.3778/j.issn.1673-9418.2008016 [8] GENG J, FAN J C, WANG H Y, et al. High-resolution SAR image classification via deep convolutional autoencoders[J]. IEEE Geoscience and Remote Sensing Letters, 2015, 12(11): 2351-2355. doi: 10.1109/LGRS.2015.2478256 [9] REN S Q, HE K M, RIRSHICK R, et al. Faster R-CNN: towards real-time object detection with region proposal networks[J]. IEEE Transactions on Pattern Analysis and Machine Intelligence, 2017, 39(6): 1137-1149. doi: 10.1109/TPAMI.2016.2577031 [10] AGRAWAL A, CHOUDHARY A. Deep materials informatics: applications of deep learning in materials science[J]. MRS Communications, 2019, 9(3): 779-792. doi: 10.1557/mrc.2019.73 [11] YE S, LI B, LI Q Y, et al. Deep neural network method for predicting the mechanical properties of composites[J]. Applied Physics Letters, 2019, 115(16): 161901. doi: 10.1063/1.5124529 [12] LI X, LIU Z L, CUI S Q, et al. Predicting the effective mechanical property of heterogeneous materials by image based modeling and deep learning[J]. Computer Methods in Applied Mechanics and Engineering, 2019, 347: 735-753. doi: 10.1016/j.cma.2019.01.005 [13] YANG C, KIM Y S, RYU S, et al. Prediction of composite microstructure stress-strain curves using convolutional neural networks[J]. Materials & Design, 2020, 189: 108509. [14] SHIN H K, AHN Y H, LEE S H, et al. Digital vision based concrete compressive strength evaluating model using deep convolutional neural network[J]. CMC Computers Materials & Continua, 2019, 61(3): 911-928. [15] 石高辉, 陈晓荣, 刘亚茹, 等. 基于卷积神经网络的人脸关键点检测算法设计[J]. 电子测量技术, 2019, 42(24): 125-130. (SHI Gaohui, CHEN Xiaorong, LIU Yaru, et al. Design of facial point detection algorithm based on convolutional neural network[J]. Electronic Measurement Technology, 2019, 42(24): 125-130.(in Chinese) [16] KRIZHEVSKY A, SUTSKEVER I, HINTON G E. ImageNet classification with deep convolutional neural networks[J]. Communications of the ACM, 2017, 60(6): 84-90. doi: 10.1145/3065386 [17] CHRISTIAN S, LIU W, JIA Y Q. Going deeper with convolutions[C]//IEEE Conference on Computer Vision and Pattern Recognition. Boston, MA, 2015. [18] HUBEL D H, WIESEL T N. Early exploration of the visual cortex[J]. Neuron, 1998, 20(3): 402-412. [19] NAIR V, HINTON G E. Rectified linear units improve restricted boltzmann machines[C]//Proceedings of the 27th International Conference on Machine Learning. Haifa, Isrel, 2010. [20] ZHANG Y H, CHEN Q Q, WANG Z Y, et al. 3D mesoscale fracture analysis of concrete under complex loading[J]. Engineering Fracture Mechanics, 2019, 220: 106646. doi: 10.1016/j.engfracmech.2019.106646 [21] 唐欣薇, 张楚汉. 基于随机改进随机骨料模型的混凝土细观断裂模拟[J]. 清华大学学报(自然科学版), 2008, 48(3): 348-351, 356. (TANG Xinwei, ZHANG Chuhan. Simulation of meso-fracture for concrete based on the developed random aggregate model[J]. Journal of Tsinghua University (Science and Technology) , 2008, 48(3): 348-351, 356.(in Chinese) doi: 10.3321/j.issn:1000-0054.2008.03.012 [22] WALARAVEN J C, REINHARDT H W. Theory and experiments on the mechanical behavior of cracks in plain and reinforced concrete subjected to shear loading[J]. Heron, 1991, 26(1A): 23-33. [23] WANG X F, YANG Z J, YATES J R, et al. Monte Carlo simulations of mesoscale fracture modelling of concrete with random aggregates and pores: a size effect study[J]. Construction and Building Materials, 2015, 80: 262-272. doi: 10.1016/j.conbuildmat.2015.02.002 [24] 刘光廷, 王宗敏. 用随机骨料模型数值模拟混凝土材料的断裂[J]. 清华大学学报(自然科学版), 1996, 36(1): 84-89. (LIU Guangyan, WANG Zongmin. Numerical simulation study of fracture of concrete materials using random aggregate model[J]. Journal of Tsinghua University (Science and Technology) , 1996, 36(1): 84-89.(in Chinese) doi: 10.3321/j.issn:1000-0054.1996.01.007 [25] 方秦, 还毅, 张亚栋, 等. ABAQUS混凝土损伤塑性模型的静力性能分析[J]. 解放军理工大学学报(自然科学版), 2007, 8(3): 254-260. (FANG Qin, HUAN Yi, ZHANG Yadong, et al. Investigation into static properties of damaged plasticity model for concrete in ABAQUS[J]. Journal of PLA University of Science and Technology (Natural Science Edition) , 2007, 8(3): 254-260.(in Chinese) [26] 陈青青, 张煜航, 张杰, 等. 含孔隙混凝土二维细观建模方法研究[J]. 应用数学和力学, 2020, 41(2): 182-194. (CHEN Qingqing, ZHANG Yuhang, ZHANG Jie, et al. Study on a 2D mesoscopic modeling method for concrete with voids[J]. Applied Mathematics and Mechanics, 2020, 41(2): 182-194.(in Chinese) [27] 章敏敏, 徐和平, 王晓洁, 等. 谷歌TensorFlow机器学习框架及应用[J]. 微型机与应用, 2017, 36(10): 58-60. (ZHANG Minmin, XU Heping, WANG Xiaojie, et al. Application of Google TensorFlow machine learning framework[J]. Microcomputer & Its Applications, 2017, 36(10): 58-60.(in Chinese) [28] JANSSON J, LI Z, SUNG W K. On finding the Adams consensus tree[J]. Information & Computation, 2017, 256: 334-347. -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号