RBF Neural Network Based Prediction on Blade Surface Pressure Fields in Compressors

-

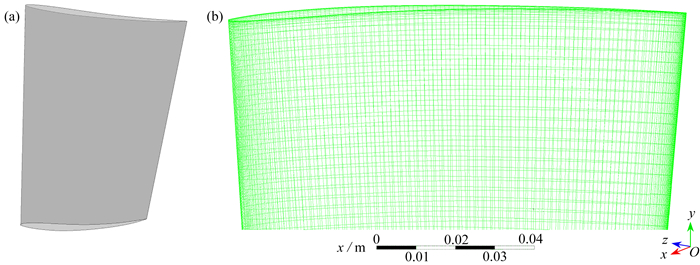

摘要: 航空发动机压气机内部流道气流特性复杂,叶片所处的涡状流场具有高压、高速、旋转和非定常等特点,因此,亟需高效、准确地计算和预测压气机叶片复杂流场的气动特性. 该文针对航空发动机叶片复杂流场的研究,通过计算流体动力学(computational fluid dynamics, CFD)方法,生成不同工作状态下的叶片表面气动载荷分布. 采用径向基函数(radial based function, RBF)神经网络建立压力面表面气动载荷预测模型,将神经网络建模方法与流场计算相结合,神经网络方法能够对基于CFD的数据集进行学习和训练,适当地弥补来自计算流体动力学的误差,为有效预测航空发动机压气机叶片复杂流场提供了参考渠道.Abstract: The airflow characteristics of the internal flow path of an aero-engine compressor are complex, and the vortex flow field around the blade is characterized by high pressure, high speed, rotation, and unsteadiness. Therefore, there is an urgent need to calculate and predict the aerodynamic characteristics of the complex flow field around the compressor blade efficiently and accurately. The computational fluid dynamics (CFD) method was used to generate the aerodynamic load distribution on the blade surface under different operating conditions for the study of the complex flow fields around aero-engine blades. The radial based function (RBF) neural network was applied to establish the pressure surface aerodynamic load prediction model, and the neural network modeling method was combined with the flow field calculation. The neural network method can learn and train the CFD-based data set to properly compensate the errors from the CFD, which provides a reference for the effective prediction of the complex flow fields around aero-engine compressor blades.

-

表 1 实验设计

Table 1. Experimental design

experiment №. rotational speed ω/(r/min) entrance flow q/(kg/s) temperature T/K outlet static pressure Po/Pa 1 4 000 1 280 150 000 2 4 000 3 300 160 000 3 4 000 5 320 170 000 4 4 000 7 340 180 000 5 4 000 9 360 190 000 6 8 000 1 280 150 000 7 8 000 3 300 160 000 8 8 000 5 320 170 000 9 8 000 7 340 180 000 10 8 000 9 360 190 000 11 12 000 1 280 150 000 12 12 000 3 300 160 000 13 12 000 5 320 170 000 14 12 000 7 340 180 000 15 12 000 9 360 190 000 16 16 000 1 280 150 000 17 16 000 3 300 160 000 18 16 000 5 320 170 000 19 16 000 7 340 180 000 20 16 000 9 360 190 000 21 20 000 1 280 150 000 22 20 000 3 300 160 000 23 20 000 5 320 170 000 24 20 000 7 340 180 000 25 20 000 9 360 190 000 26 4 000 5 300 150 000 27 4 000 7 300 150 000 28 8 000 5 300 150 000 29 8 000 7 300 150 000 30 12 000 5 300 150 000 31 12 000 7 300 150 000 32 16 000 5 300 150 000 33 16 000 7 300 150 000 34 20 000 5 300 150 000 35 20 000 7 300 150 000 36 4 000 3 300 150 000 37 8 000 3 300 150 000 38 12 000 3 300 150 000 39 16 000 3 300 150 000 40 20 000 3 300 150 000 表 2 误差对比结果

Table 2. Error comparison results

rotational speed ω/(r/min) 4 000 8 000 12 000 16 000 20 000 error δ/% 4.59 4.29 2.42 1.33 5.52 表 3 其他转速条件下的预测误差

Table 3. Prediction errors at other speed conditions

rotational speed ω/(r/min) entrance flow q/(kg/s) temperature T/K outlet static pressure Po/Pa error δ/% 5 000 3 300 150 000 1.2 6 000 3 300 150 000 2.3 7 000 3 300 150 000 2.6 9 000 3 300 150 000 2.7 10 000 3 300 150 000 3.1 11 000 3 300 150 000 2.4 13 000 3 300 150 000 2.6 14 000 3 300 150 000 3.1 15 000 3 300 150 000 2.6 17 000 3 300 150 000 2.4 18 000 3 300 150 000 2.5 19 000 3 300 150 000 3.0 -

[1] LI C F, SHE H X, TANG Q S, et al. The coupling vibration characteristics of a flexible shaft-disk-blades system with mistuned features[J]. Applied Mathematical Modelling, 2019, 67: 557-572. doi: 10.1016/j.apm.2018.09.041 [2] YANG J S, XIE J S, CHEN G G, et al. An efficient method for vibration equations with time varying coefficients and nonlinearities[J]. Journal of Low Frequency Noise, Vibration and Active Control, 2021, 40(4): 1744-1763. doi: 10.1177/14613484211025151 [3] ZHAO Y M, XIA Z H, SHI Y P, et al. Constrained large-eddy simulation of laminar-turbulent transition in channel flow[J]. Physics of Fluids, 2014, 26(9): 095103. doi: 10.1063/1.4895589 [4] ZHAO Y M, YANG Y, CHEN S Y. Evolution of material surfaces in the temporal transition in channel flow[J]. Journal of Fluid Mechanics, 2016, 793: 840-876. doi: 10.1017/jfm.2016.152 [5] BAI B, BAI G C, LI C. Application of multi-stage multi-objective multi-disciplinary agent model based on dynamic substructural method in mistuned blisk[J]. Aerospace Science and Technology, 2015, 46: 104-115. doi: 10.1016/j.ast.2015.06.030 [6] 王超, 王贵东, 白鹏. 飞行仿真气动力数据机器学习建模方法[J]. 空气动力学学报, 2019, 37(3): 488-497. https://www.cnki.com.cn/Article/CJFDTOTAL-KQDX201903016.htmWANG Chao, WANG Guidong, BAI Peng. Machine learning method for aerodynamic modeling based on flight simulation data[J]. Acta Aerodynamica Sinica, 2019, 37(3): 488-497. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-KQDX201903016.htm [7] BALLA K, SEVILLA R, HASSAN O, et al. An application of neural networks to the prediction of aerodynamic coefficients of aerofoils and wings[J]. Applied Mathematical Modelling, 2021, 96: 456-479. doi: 10.1016/j.apm.2021.03.019 [8] LOU J, ZHU W, WANG H, et al. Prediction of residual stress for machining aviation engine blade based on RBF neural network[J]. Computer Integrated Manufacturing Systems, 2018, 24(2): 361-370. [9] 陈海昕, 邓凯文, 李润泽. 机器学习技术在气动优化中的应用[J]. 航空学报, 2019, 40(1): 52-68. https://www.cnki.com.cn/Article/CJFDTOTAL-HKXB201901004.htmCHEN Haixin, DENG Kaiwen, LI Runze. Utilization of machine learning technology in aerodynamic optimization[J]. Acta Aeronautica et Astronautica Sinica, 2019, 40(1): 52-68. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-HKXB201901004.htm [10] 赵翔, 茹东恒, 王鹏, 等. 基于NARX神经网络方法的汽轮机转子关键部位应力预测[J]. 应用数学和力学, 2021, 42(8): 771-784. doi: 10.21656/1000-0887.410372ZHAO Xiang, RU Dongheng, WANG Peng, et al. On the stress prediction of key components in steam turbine rotors based on the NARX neural network[J]. Applied Mathematics and Mechanics, 2021, 42(8): 771-784. (in Chinese) doi: 10.21656/1000-0887.410372 [11] LINSE D J, STENGEL R F. Identification of aerodynamic coefficients using computational neural networks[J]. Journal of Guidance Control and Dynamics, 1993, 16(6): 1018-1025. doi: 10.2514/3.21122 [12] BRUNTON S L, NOACK B R, KOUMOUTSAKOS P. Machine learning for fluid mechanics[J]. Annual Review of Fluid Mechanics, 2020, 52(1): 477-508. doi: 10.1146/annurev-fluid-010719-060214 [13] 张天姣, 钱炜祺, 周宇, 等. 人工智能与空气动力学结合的初步思考[J]. 航空工程进展, 2019, 10(1): 1-11. https://www.cnki.com.cn/Article/CJFDTOTAL-HKGC201901002.htmZHANG Tianjiao, QIAN Weiqi, ZHOU Yu, et al. Preliminary thoughts on the combination of artificial intelligence and aerodynamics[J]. Advances in Aeronautical Science and Engineering, 2019, 10(1): 1-11. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-HKGC201901002.htm [14] 何磊, 钱炜祺, 汪清, 等. 机器学习方法在气动特性建模中的应用[J]. 空气动力学学报, 2019, 37(3): 470-479. https://www.cnki.com.cn/Article/CJFDTOTAL-KQDX201903014.htmHE Lei, QIAN Weiqi, WANG Qing, et al. Applications of machine learning for aerodynamic characteristic modeling[J]. Acta Aerodynamica Sinica, 2019, 37(3): 470-479. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-KQDX201903014.htm [15] FEI T, JI L C, YI W L. Performance characteristic modeling for 2D compressor cascades[J]. International Journal of Turbo and Jet Engines, 2019, 39(3): 367-382. [16] ZHAO Y, MENG Y, YU P, et al. Prediction of fluid force exerted on bluff body by neural network method[J]. Journal of Shanghai Jiaotong University (Science), 2020, 25(2): 186-192. doi: 10.1007/s12204-019-2140-0 [17] PAZIREH S, DEFOE J. A new loss generation body force model for fan/compressor blade rows: application to uniform and non-uniform inflow in rotor 67[J]. Journal of Turbomachinery, 2022, 144(6): 061005. doi: 10.1115/1.4053231 [18] REN L H, YE Z F, ZHAO Y P. A modeling method for aero-engine by combining stochastic gradient descent with support vector regression[J]. Aerospace Science and Technology, 2020, 99: 105775. [19] ZHANG M M, HAO S R, HOU A P. Study on the intelligent modeling of the blade aerodynamic force in compressors based on machine learning[J]. Mathematics, 2021, 9(5): 476. [20] LI K, KOU J Q, ZHANG W W. Deep neural network for unsteady aerodynamic and aeroelastic modeling across multiple Mach numbers[J]. Nonlinear Dynamics, 2019, 96(3): 2157-2177. [21] QIN S, WANG S Y, WANG L Y, et al. Multi-objective optimization of cascade blade profile based on reinforcement learning[J]. Applied Sciences-Basel, 2021, 11(1): 106. [22] QIN S, WANG S Y, SUN G, et al. New approach of inverse design of transonic compressor rotor blade via prescribed isentropic Mach distributions without modification of governing equations[J]. Proceedings of the Institution of Mechanical Engineers(Part G): Journal of Aerospace Engineering, 2022, 236(7): 1422-1438. [23] 廖鹏, 姚磊江, 白国栋, 等. 基于深度学习的混合翼型前缘压力分布预测[J]. 航空动力学报, 2019, 34(8): 1751-1758. https://www.cnki.com.cn/Article/CJFDTOTAL-HKDI201908013.htmLIAO Peng, YAO Leijiang, BAI Guodong, et al. Prediction of hybrid airfoil leading edge pressure distribution based on deep learning[J]. Journal of Aerospace Power, 2019, 34(8): 1751-1758. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-HKDI201908013.htm [24] 王沐晨, 李立州, 张珺, 等. 基于卷积神经网络气动力降阶模型的翼型优化方法[J]. 应用数学和力学, 2022, 43(1): 77-83. doi: 10.21656/1000-0887.420137WANG Muchen, LI Lizhou, ZHANG Jun, et al. An airfoil optimization method based on the convolutional neural network aerodynamic reduced order model[J]. Applied Mathematics and Mechanics, 2022, 43(1): 77-83. (in Chinese) doi: 10.21656/1000-0887.420137 [25] 杜周, 徐全勇, 宋振寿, 等. 基于深度学习的压气机叶型气动特性预测[J]. 航空动力学报, 2023, 38(9): 2251-2260. https://www.cnki.com.cn/Article/CJFDTOTAL-HKDI202309020.htmDU Zhou, XU Quanyong, SONG Zhenshou, et al. Prediction of aerodynamic characteristics of compressor blade profile based on deep learning[J]. Journal of Aerospace Power, 2023, 38(9): 2251-2260. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-HKDI202309020.htm [26] 王金城, 齐进, 吴锤结. 不可压缩Navier-Stokes方程最优动力系统建模和分析[J]. 应用数学和力学, 2020, 41(1): 1-15. doi: 10.21656/1000-0887.400279WANG Jincheng, QI Jin, WU Chuijie. Analysis and modelling optimal dynamical systems of incompressible Navier-Stokes equations[J]. Applied Mathematics and Mechanics, 2020, 41(1): 1-15. (in Chinese) doi: 10.21656/1000-0887.400279 -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号