Asymptotic Solutions of Plastic Stress and Displacement at V-Notch Tips Under Anti-Plane Shear

-

摘要:

提出了一种确定幂硬化材料反平面V形切口尖端应力和位移渐近解的主导项和高阶项的有效方法。首先通过在弹塑性理论基本方程中引入V形切口尖端应力场和位移场的渐近级数展开,建立以应力和位移为特征函数的非线性和线性常微分方程组。然后采用插值矩阵法求解常微分方程组,可得到多阶应力特征指数和其相对应的特征函数。该方法具有通用性强、精度高等优点,可处理任意开口角度和应变硬化指数的V形切口。典型算例验证了该方法的准确性和有效性。

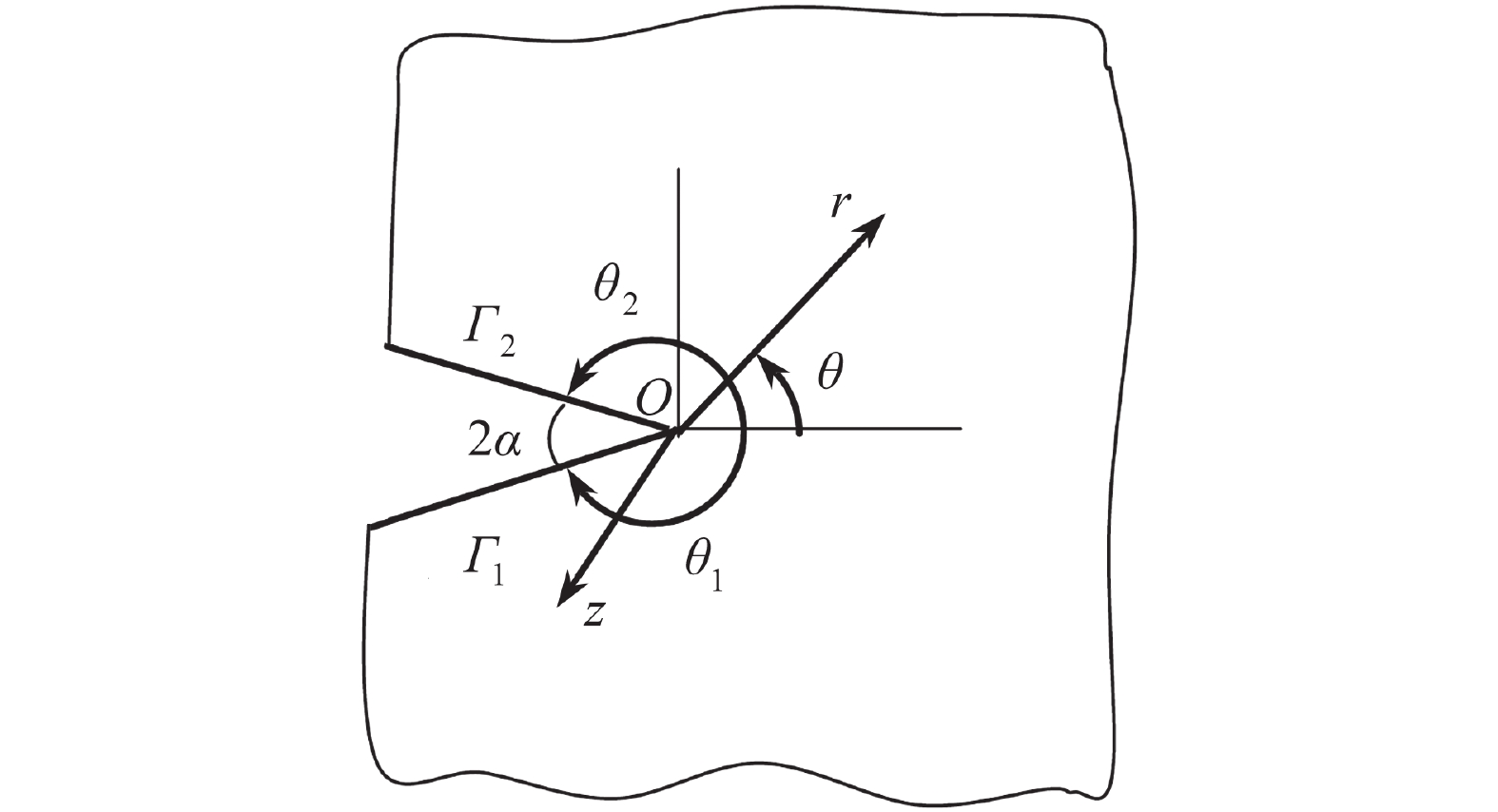

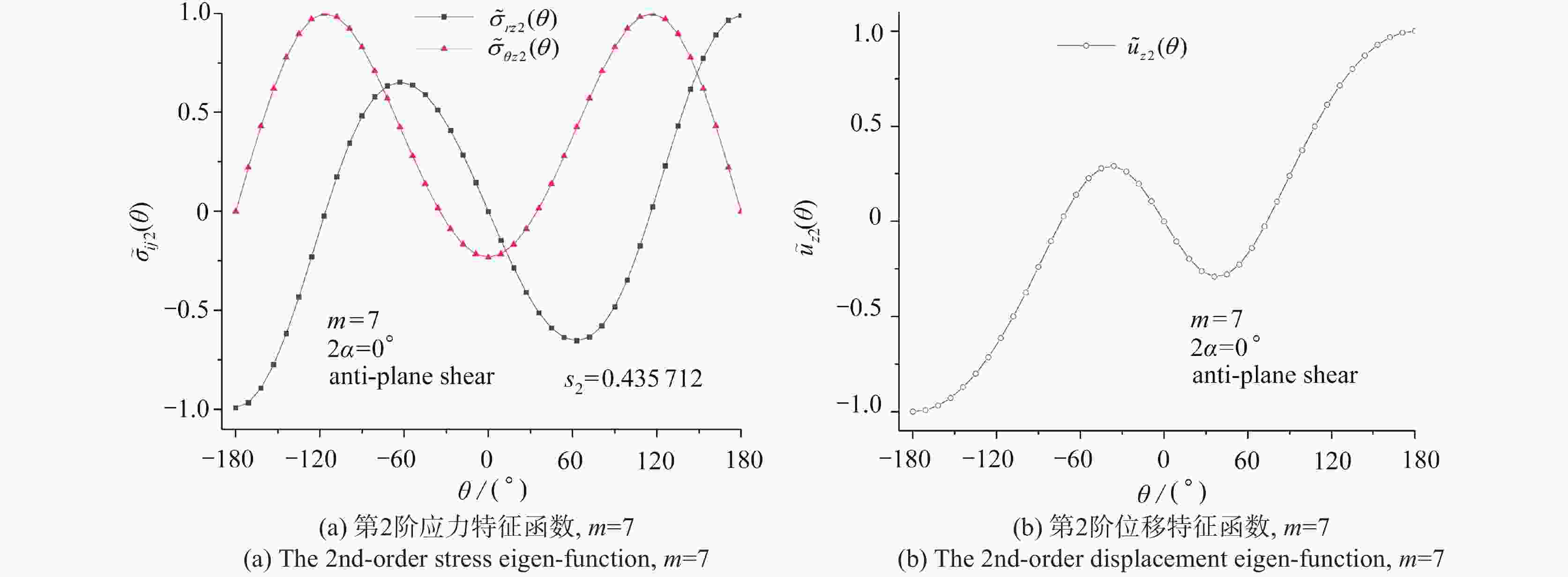

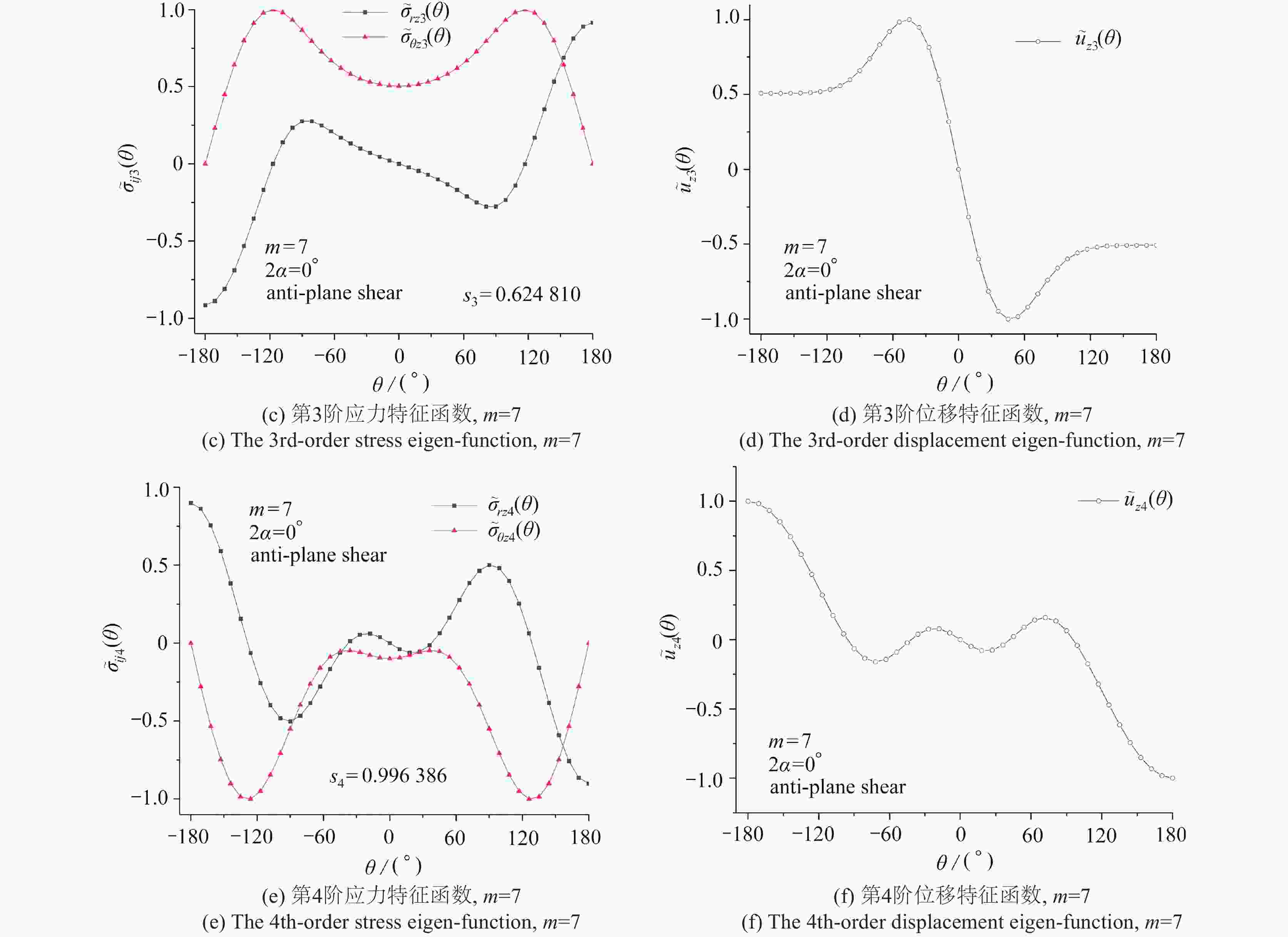

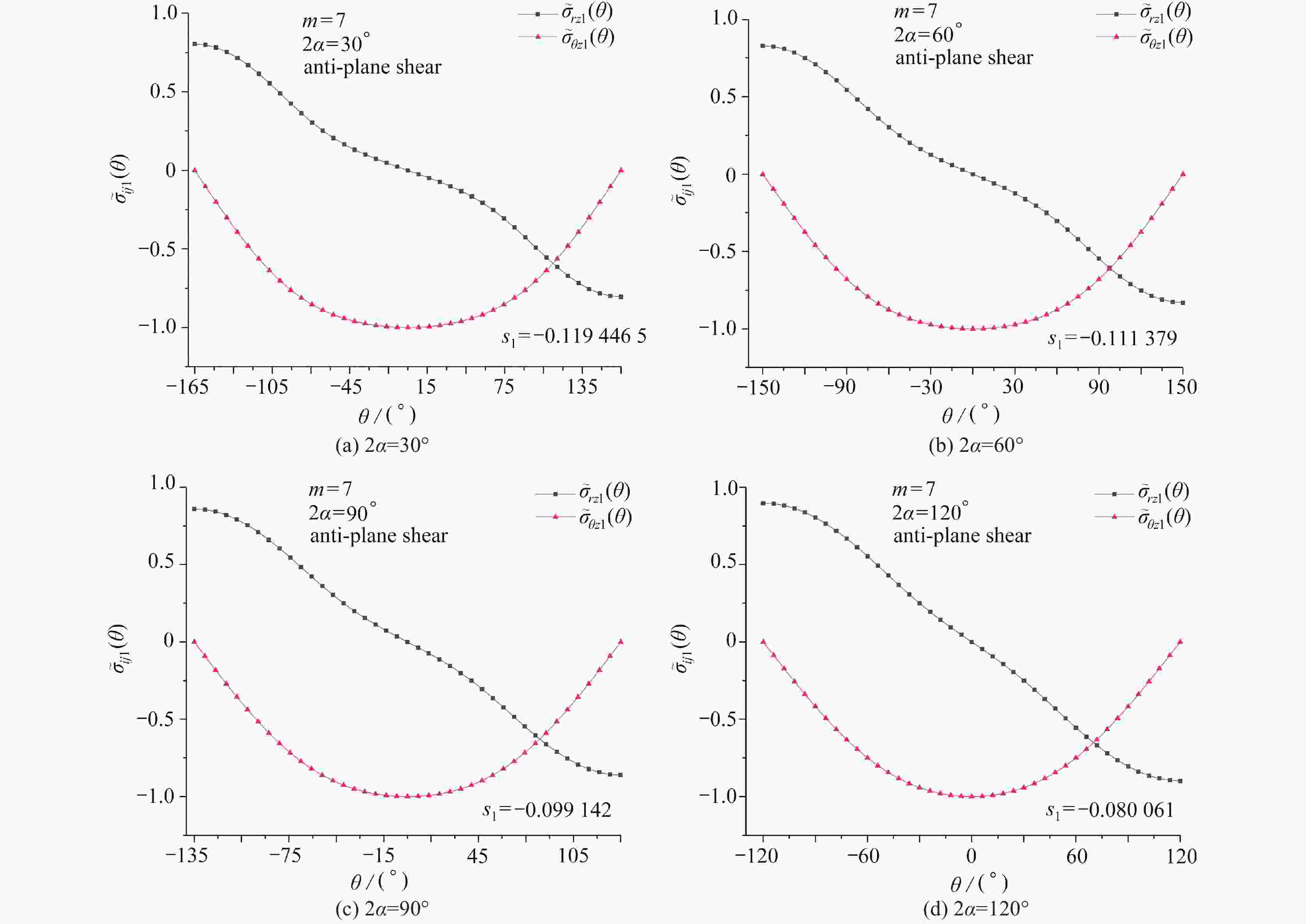

Abstract:An efficient method was developed to determine the first- and high-order terms of asymptotic solutions of plastic stress and displacement near V-notch tips under anti-plane shear in power-law hardening materials. Through introduction of the asymptotic series expansions of stress and displacement fields around the V-notch tip into the fundamental equations of the elastoplastic theory, the governing ordinary differential equations (ODEs) with the stress and displacement eigen-functions were established. Then the interpolating matrix method was employed to solve the resulting nonlinear and linear ODEs. Consequently, the high-order stress exponents and the associated eigen-solutions were obtained. The presented method, being capable of dealing with the V-notches with arbitrary opening angles and strain hardening indexes under anti-plane shear, has the advantages of great versatility and high accuracy. Typical examples were given to demonstrate the accuracy and effectiveness of this method.

-

Key words:

- elastoplasticity /

- anti-plane /

- V-notch /

- asymptotic solution /

- singularity

-

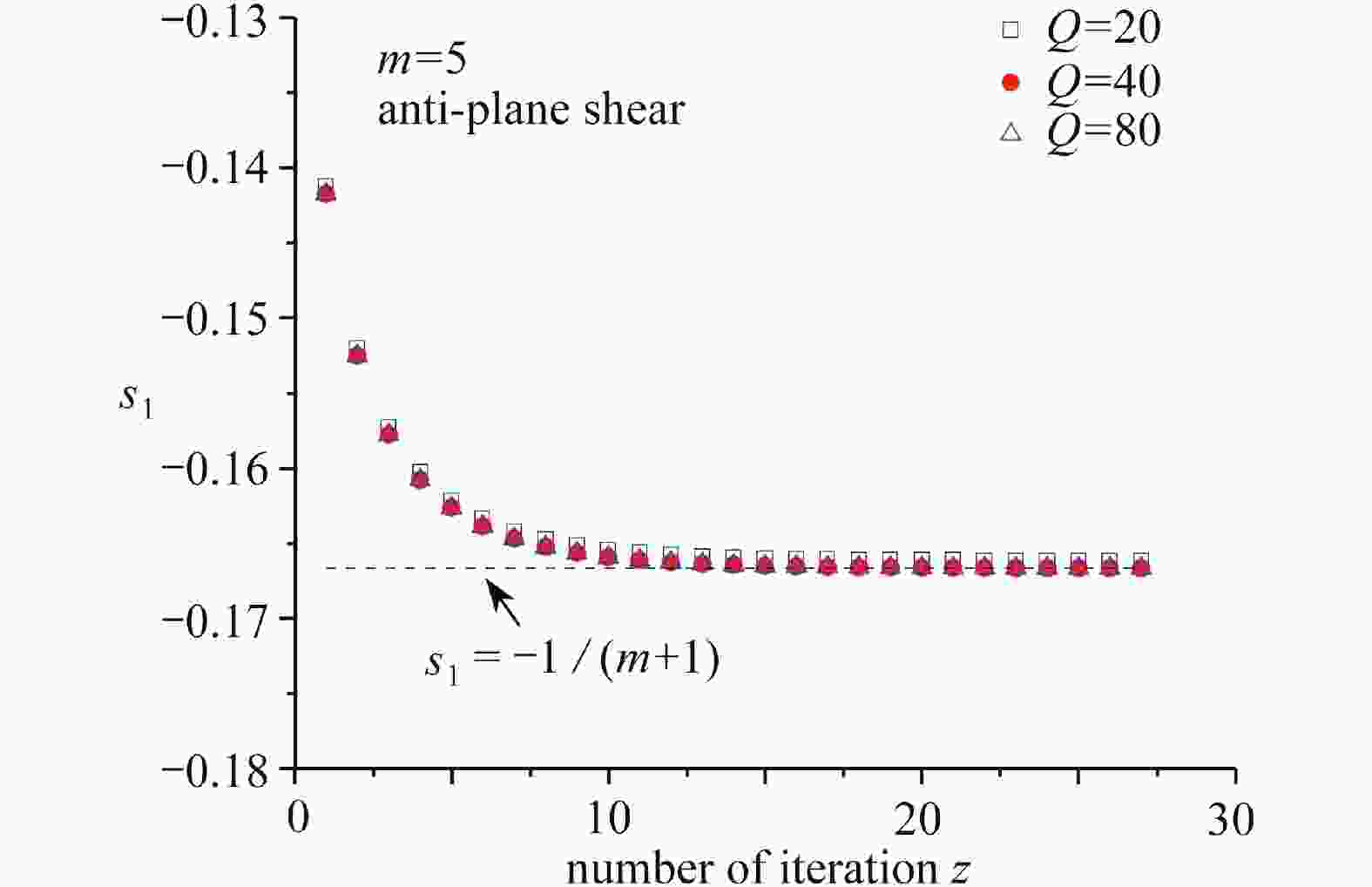

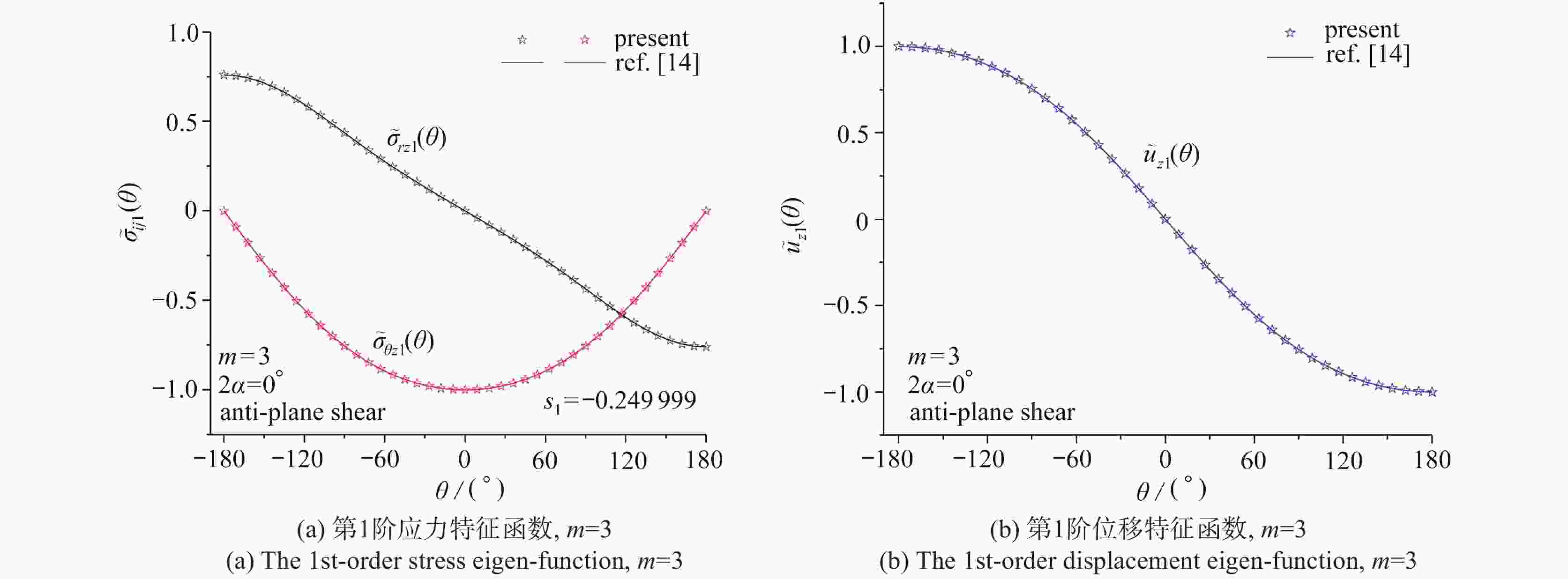

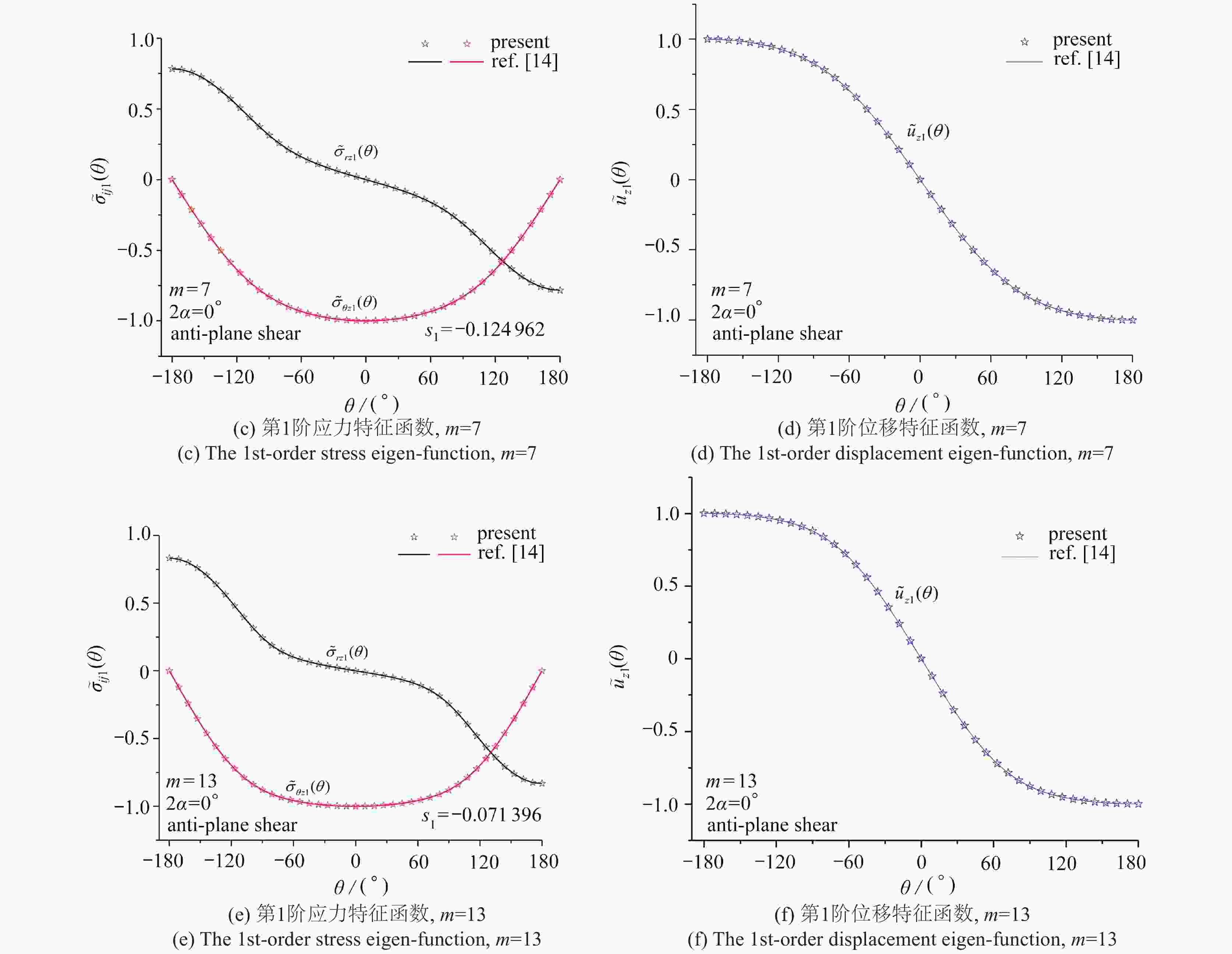

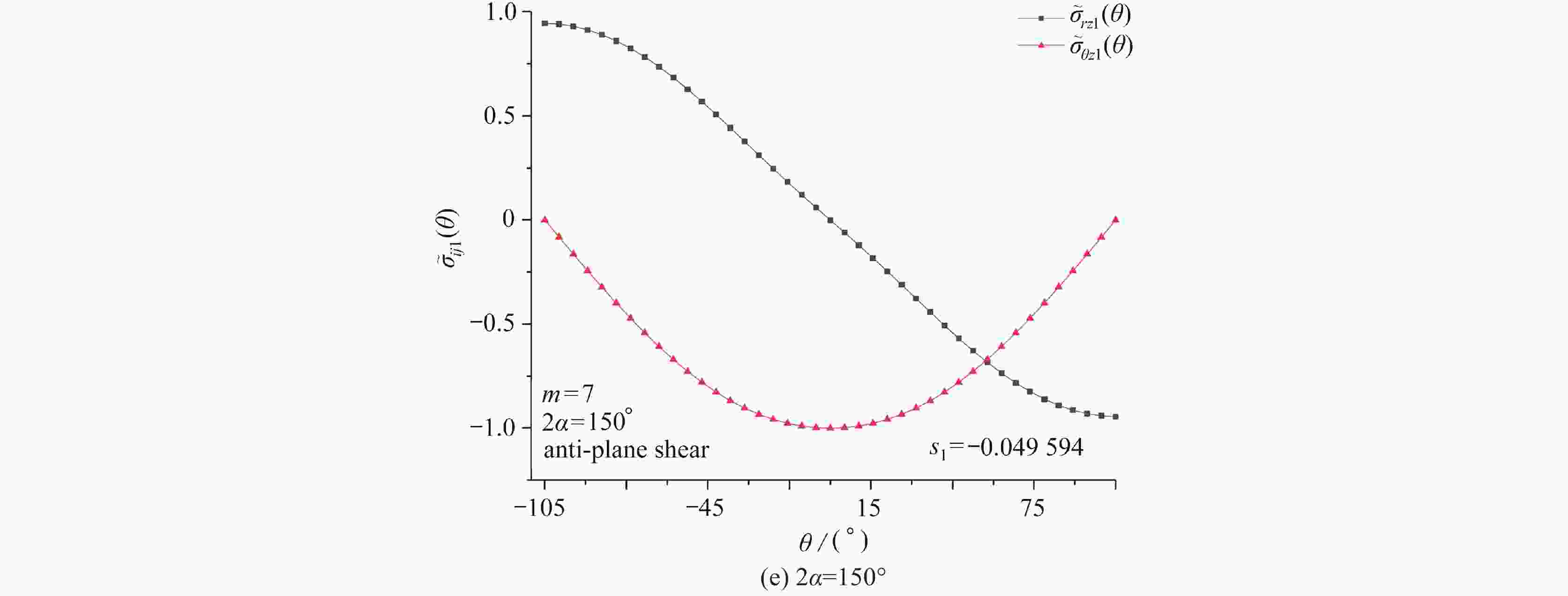

表 1 反平面Ⅲ型裂纹前4阶应力特征指数随硬化指数m的变化

Table 1. Stress exponent

$ {s_k} $ of the mode Ⅲ crack with various m values$ {s_k} $ method m=3 m=5 m=7 m=10 m=13 $ {s_{\text{1}}} $ present (Q=20) −0.249 999 −0.166 666 −0.124 999 −0.090 907 −0.071 426 present (Q =40) −0.249 999 −0.166 667 −0.125 000 −0.090 909 −0.071 429 present (Q =80) −0.249 999 −0.166 667 −0.125 000 −0.090 909 −0.071 429 ref. [14] −0.250 000 −0.166 667 −0.125 000 −0.090 909 −0.071 429 $ {s_{\text{2}}} $ present (Q =20) 0.249999# 0.499998# 0.437490 0.365759 0.314434 present (Q =40) 0.249 999# 0.500 001# 0.435 761 0.363 758 0.312 255 present (Q =80) 0.249 999# 0.500 001# 0.435 666 0.363 646 0.312 133 ref. [14] 0.250 000# 0.500 000# 0.435 660 0.363 636 0.312 094 $ {s_{\text{3}}} $ present (Q =20) 0.574 150 0.501 559 0.624 995# 0.727 256# 0.700 294× present (Q =40) 0.572 948 0.500 086 0.625 000# 0.727 272# 0.695 939× present (Q =80) 0.572 879 0.500 004 0.625 000# 0.727 272# 0.695 695× ref. [14] 0.572 876 0.500 000 0.625 000# 0.727 273# 0.695 617× $ {s_{\text{4}}} $ present (Q =20) 0.749 997# 1.166 662# 0.999 979× 0.822 425× 0.785 686# present (Q =40) 0.749 997# 1.166 669# 0.996 522× 0.818 425× 0.785 719# present (Q =80) 0.749 997# 1.166 669# 0.996 332× 0.818 201× 0.785 719# ref. [14] 0.750 000# 1.166 667# 0.996 320× 0.818 182× 0.785 714# 表 2 反平面V形切口(

$ {\text{2}}\alpha {\text{ = 3}}{{\text{0}}^ \circ } $ )前4阶应力特征指数随硬化指数m的变化Table 2. Stress exponent

$ {s_k} $ of the mode Ⅲ V-notch with$ {\text{2}}\alpha {\text{ = 3}}{{\text{0}}^ \circ } $ for various m values$ {s_k} $ method m=3 m=5 m=7 m=10 m=13 $ {s_{\text{1}}} $ present(Q=20) −0.232204 −0.157527 −0.119464 −0.087783 −0.069413 present(Q=40) −0.232206 −0.157527 −0.119465 −0.087784 −0.069415 present(Q=80) −0.232206 −0.157527 −0.119465 −0.087784 −0.069415 ref. [17] −0.232206 −0.157564 −0.119502 −0.087824 −0.069457 $ {s_{\text{2}}} $ present(Q=20) 0.232204# 0.472581# 0.554001 0.472991 0.413208 present(Q=40) 0.232206# 0.472581# 0.551878 0.470411 0.410316 present(Q=80) 0.232206# 0.472581# 0.551876 0.470409 0.410314 ref. [17] − − 0.551851 0.470288 0.409963 $ {s_{\text{3}}} $ present(Q=20) 0.696612× 0.623794 0.597320# 0.702264# 0.763543# present(Q=40) 0.696618× 0.621968 0.597325# 0.702272# 0.763565# present(Q=80) 0.696618× 0.621972 0.597325# 0.702272# 0.763565# ref. [17] − 0.622051 − − − $ {s_{\text{4}}} $ present(Q=20) 0.700023 1.102689# 1.227466× 1.033765× 0.895829× present(Q=40) 0.698686 1.102689# 1.223221× 1.028606× 0.890047× present(Q=80) 0.698682 1.102689# 1.223217× 1.028602× 0.890043× ref. [17] 0.698604 − − − − 表 3 反平面V形切口(

$ {\text{2}}\alpha {\text{ = 15}}{{\text{0}}^ \circ } $ )前4阶应力特征指数随硬化指数m的变化Table 3. Stress exponent

$ {s_k} $ of the mode Ⅲ V-notch with$ {\text{2}}\alpha {\text{ = 15}}{{\text{0}}^ \circ } $ for various m values$ {s_k} $ method m=3 m=5 m=7 m=10 m=13 $ {s_{\text{1}}} $ present(Q=20) −0.080378 −0.060350 −0.049587 −0.039967 −0.033919 present(Q=40) −0.080383 −0.060356 −0.049564 −0.039974 −0.033925 present(Q=80) −0.080383 −0.060356 −0.049593 −0.039974 −0.033925 ref. [17] −0.080384 −0.060369 −0.049614 −0.040000 −0.033956 $ {s_{\text{2}}} $ present(Q=20) 0.080378# 0.181051# 0.247935# 0.319736# 0.373109#` present(Q=40) 0.080383# 0.181068# 0.247970# 0.319792# 0.373175#` present(Q=80) 0.080383# 0.181068# 0.247965# 0.319792# 0.373175#` ref. [17] − − − − − $ {s_{\text{3}}} $ present(Q=20) 0.241134# 0.422452# 0.545457# 0.679439# 0.780137# present(Q=40) 0.241149# 0.422492# 0.545534# 0.679558# 0.780275# present(Q=80) 0.241149# 0.422492# 0.545523# 0.679558# 0.780275# ref. [17] − − − − − $ {s_{\text{4}}} $ present(Q=20) 1.589836 1.556131 1.520007 1.470114 1.426214 present(Q=40) 1.587821 1.553694 1.516597 1.464221 1.417315 present(Q=80) 1.587820 1.553693 1.516597 1.464220 1.417314 ref. [17] 1.587794 1.553562 1.516332 1.463944 1.416870 表 4 反平面V形切口(

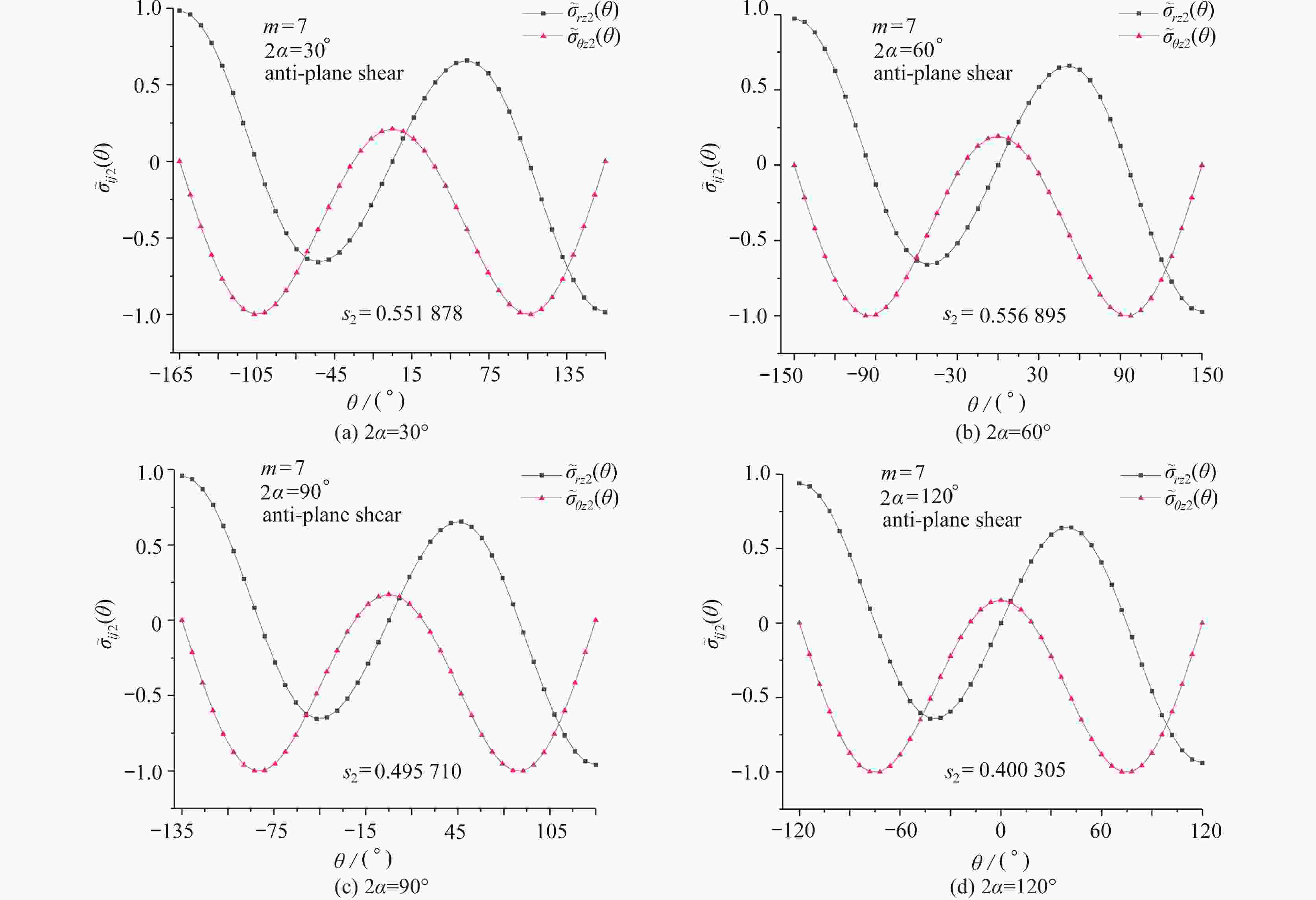

$ {\text{2}}\alpha {\text{ = 6}}{{\text{0}}^ \circ } $ )前4阶应力特征指数随硬化指数m的变化(Q=40)Table 4. Stress exponent

$ {s_k} $ of the mode Ⅲ V-notch with$ {\text{2}}\alpha {\text{ = 6}}{{\text{0}}^ \circ } $ for various m values (Q=40)$ {s_k} $ method m=3 m=5 m=7 m=10 m=13 $ {s_{\text{1}}} $ present −0.209034 −0.144787 −0.111379 −0.083025 −0.066275 ref. [17] −0.209035 −0.144820 −0.111421 −0.083068 −0.066323 $ {s_{\text{2}}} $ present 0.209034# 0.434361# 0.556895# 0.613636 0.545403 ref. [17] − − − 0.613578 0.545247 $ {s_{\text{3}}} $ present 0.627102# 0.775407 0.702317 0.664200# 0.729025# ref. [17] − 0.775369 0.702299 − − $ {s_{\text{4}}} $ present 0.851750 1.013509# 1.225169# 1.310297× 1.157081× ref. [17] 0.851659 − − − − 表 5 反平面V形切口(

$ {\text{2}}\alpha {\text{ = 9}}{{\text{0}}^ \circ } $ )前4阶应力特征指数随硬化指数m的变化(Q=40)Table 5. Stress exponent

$ {s_k} $ of the mode Ⅲ V-notch with$ {\text{2}}\alpha {\text{ = 9}}{{\text{0}}^ \circ } $ for various m values (Q=40)$ {s_k} $ method m=3 m=5 m=7 m=10 m=13 $ {s_{\text{1}}} $ present −0.178394 −0.126571 −0.099142 −0.075360 −0.060999 ref. [17] −0.178395 −0.126599 −0.099179 −0.075403 −0.061047 $ {s_{\text{2}}} $ present 0.178394# 0.379713# 0.495710# 0.602880# 0.670989# ref. [17] − − − − − $ {s_{\text{3}}} $ present 0.535182# 0.885997# 0.899889 0.809746 0.736893 ref. [17] − − 0.899826 0.809670 0.736783 $ {s_{\text{4}}} $ present 1.040992 0.970537 1.090562# 1.281120# 1.402977# ref. [17] 1.040889 0.970465 − − − 表 6 反平面V形切口(

$ {\text{2}}\alpha {\text{ = 12}}{{\text{0}}^ \circ } $ )前4阶应力特征指数随硬化指数m的变化(Q=40)Table 6. Stress exponents

$ {s_k} $ of the mode Ⅲ V-notch with$ {\text{2}}\alpha {\text{ = 12}}{{\text{0}}^ \circ } $ for various m values (Q=40)$ {s_k} $ method m=3 m=5 m=7 m=10 m=13 $ {s_{\text{1}}} $ present −0.137145 −0.099974 −0.080061 −0.060462 −0.051585 ref. [17] −0.137146 −0.100000 −0.080094 −0.062500 −0.051628 $ {s_{\text{2}}} $ present 0.137145# 0.299922# 0.400305# 0.483696# 0.567435# ref. [17] − − − − − $ {s_{\text{3}}} $ present 0.411435# 0.699818# 0.880671# 1.027854# 1.013736 ref. [17] − − − − 1.013494 $ {s_{\text{4}}} $ present 1.279549 1.222471 1.162660 1.082304 1.186455# ref. [17] 1.279434 1.222375 1.162546 1.082129 − 表 7 反平面V形切口前4阶应力特征指数随硬化指数m和张角2α的变化 ( Q =40)

Table 7. Stress exponents

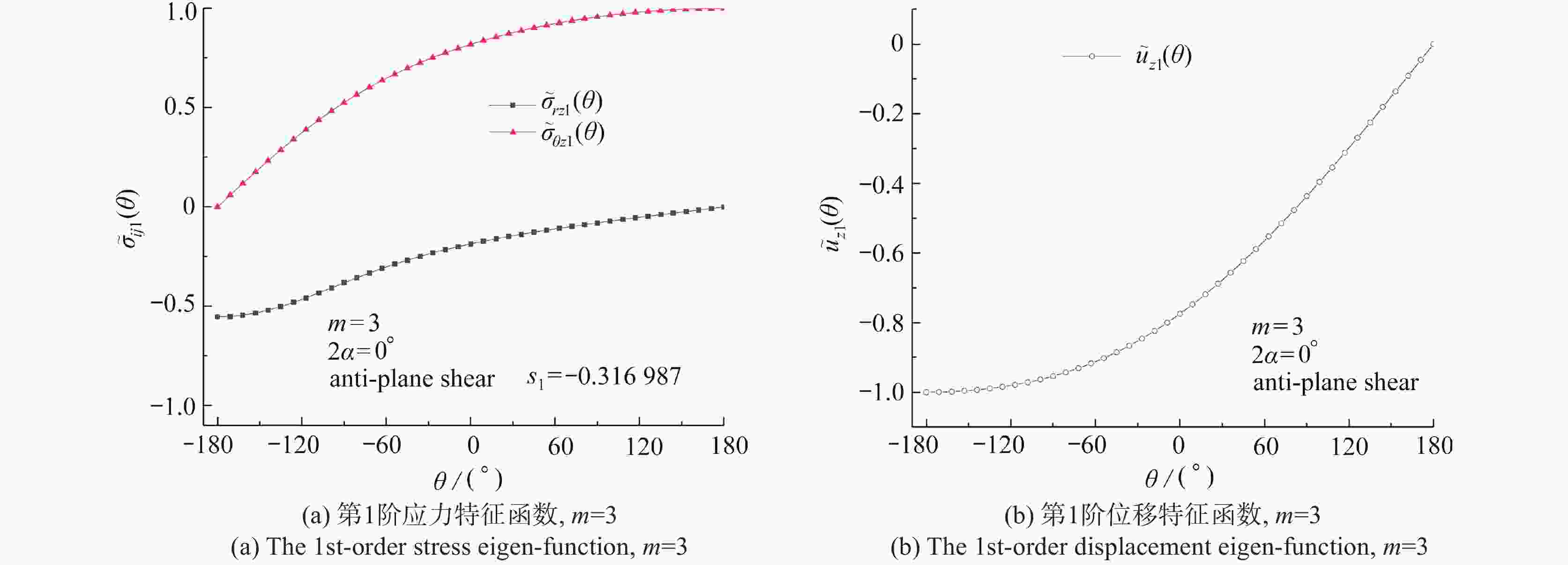

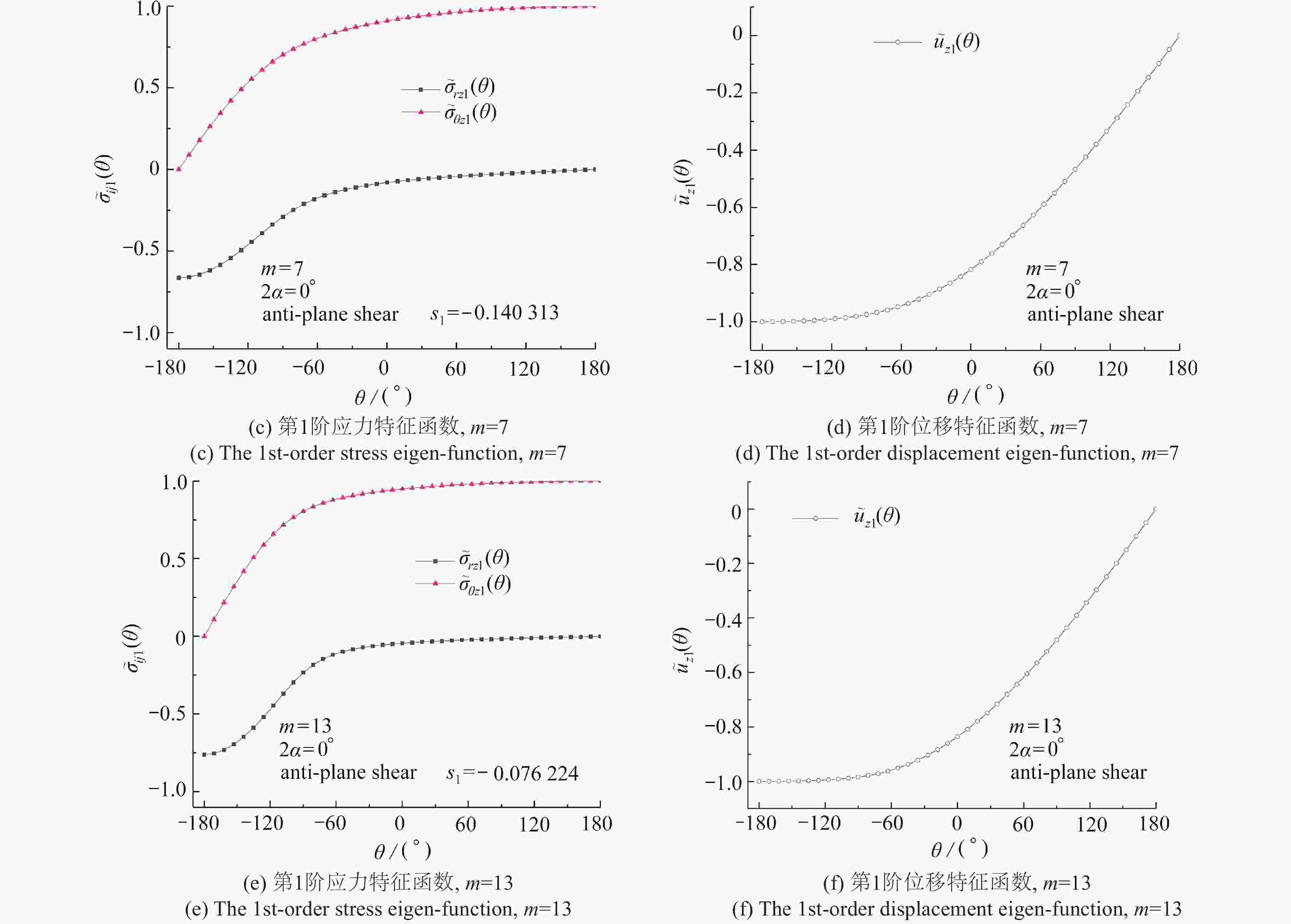

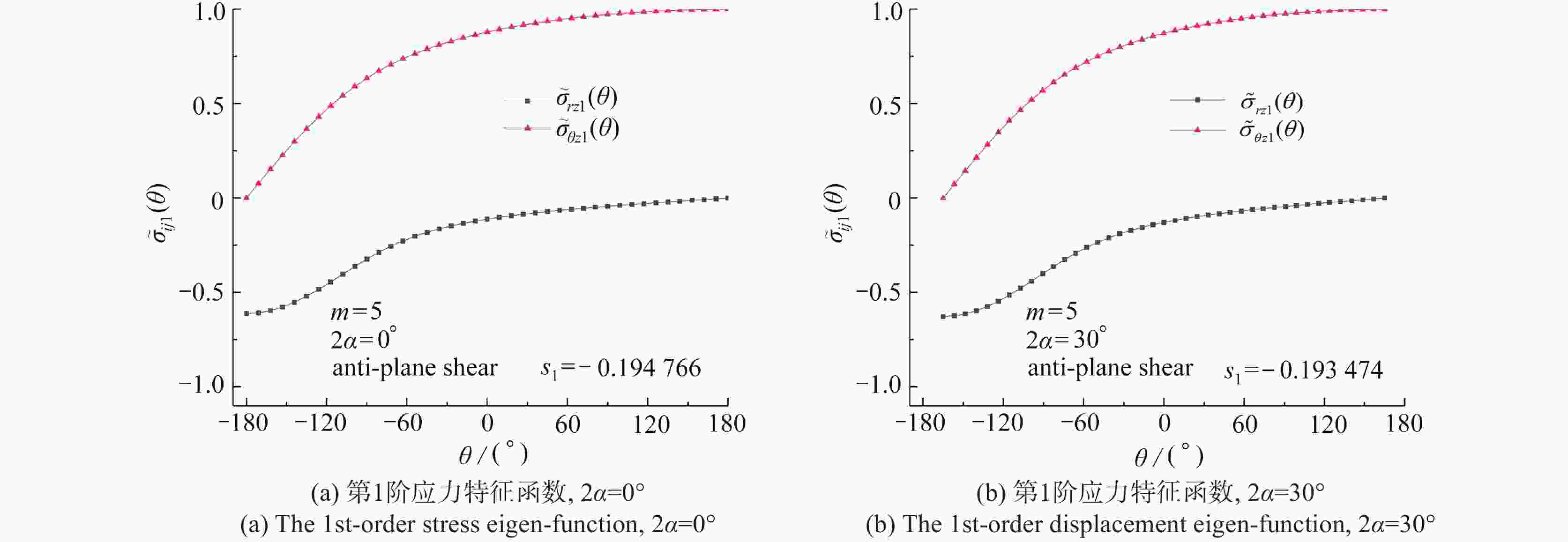

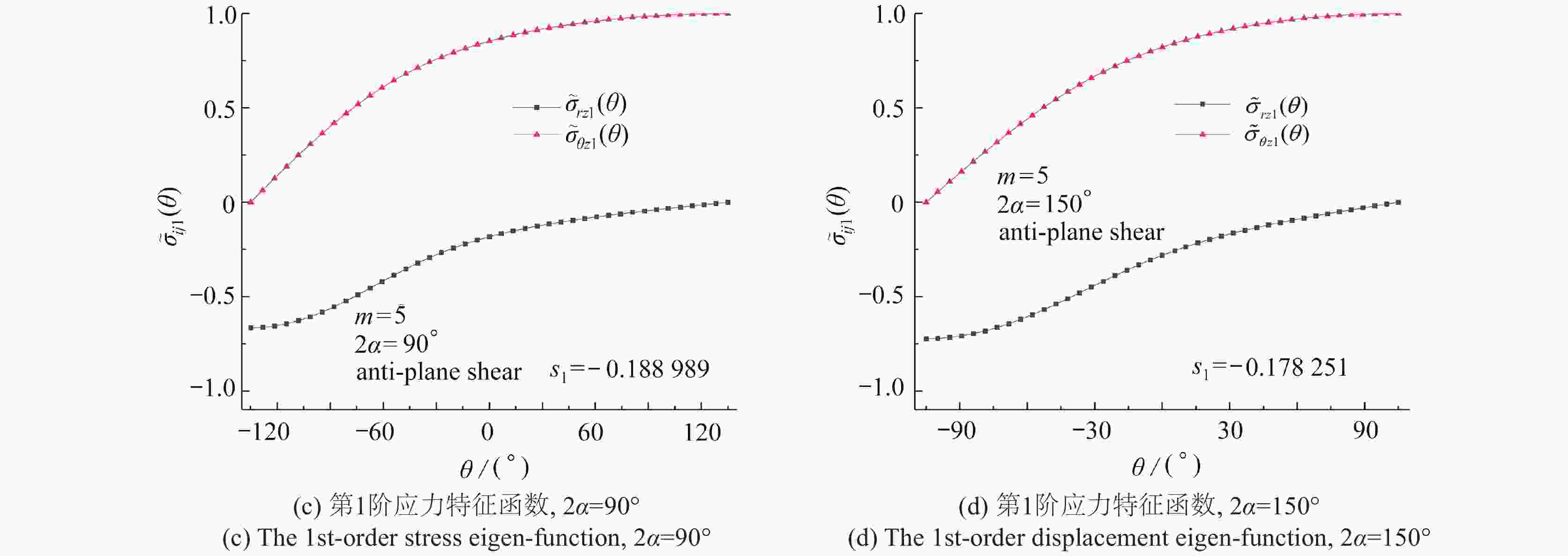

$ {s_k} $ of the mode Ⅲ V-notch for various m values and$ {\text{2}}\alpha $ (Q=40)$ {s_k} $ $ {\text{2}}\alpha $/(°) m=3 m=5 m=7 m=10 m=13 $ {s_{\text{1}}} $ 0 −0.316987 −0.194766 −0.140313 −0.098797 −0.076224 30 −0.313242 −0.193473 −0.139669 −0.098487 −0.076043 90 −0.300944 −0.188989 −0.137387 −0.097374 −0.075386 150 −0.274774 −0.178251 −0.131633 −0.094459 −0.073631 $ {s_{\text{2}}} $ 0 −0.049037 −0.026170 −0.017810 −0.012034 −0.009085 30 −0.000702 0.008722 0.009252 0.008153 0.006996 90 0.138739 0.116011 0.095654 0.074849 0.061274 150 0.274774# 0.321572 0.272393 0.220346 0.184745 $ {s_{\text{3}}} $ 0 0.218913× 0.142426× 0.104693× 0.074729× 0.058054× 30 0.311838× 0.210917× 0.158173× 0.114793× 0.090035× 90 0.300944× 0.421011× 0.328695× 0.247072× 0.197934× 150 0.380293 0.534753# 0.658165# 0.535151× 0.443121× $ {s_{\text{4}}} $ 0 0.285422 0.213317 0.169289 0.129282 0.104644 30 0.313242# 0.285697 0.228736 0.176303 0.143628 90 0.638404 0.50008 0.410023 0.323996 0.268649 150 0.824322× 0.821395× 0.676419× 0.623227 0.531023 -

[1] 李聪, 牛忠荣, 胡宗军, 等. 求解双材料裂纹结构全域应力场的扩展边界元法[J]. 应用数学和力学, 2019, 40(8): 926-937. (LI Cong, NIU Zhongrong, HU Zongjun, et al. Computation of total stress fields for cracked bi-material structures with the extended boundary element method[J]. Applied Mathematics and Mechanics, 2019, 40(8): 926-937.(in Chinese) [2] HUTCHINSON J W. Singular behavior at the end of a tensile crack in a hardening material[J]. Journal of the Mechanics and Physics of Solids, 1968, 16(1): 13-31. doi: 10.1016/0022-5096(68)90014-8 [3] RICE J R, ROSENGREN G F. Plane strain deformation near a crack tip in a power-law hardening material[J]. Journal of the Mechanics and Physics of Solids, 1968, 16(1): 1-12. doi: 10.1016/0022-5096(68)90013-6 [4] KUANG Z, XU X. Stress and strain fields at the tip of a sharp V-notch in a power-hardening material[J]. International Journal of Fracture, 1987, 35: 39-53. doi: 10.1007/BF00034533 [5] XIA L, WANG T C. Singular behaviour near the tip of a sharp V-notch in a power law hardening material[J]. International Journal of Fracture, 1993, 59(1): 83-93. doi: 10.1007/BF00032219 [6] LI Y C, WANG T C. High-order asymptotic field of tensile plane-strain nonlinear crack problems[J]. Scientia Sinica(Series A) , 1986, 29(9): 941-955. [7] SHARMA S M, ARAVAS N. On the development of variable-separable asymptotic elastoplastic solutions for interfacial cracks[J]. International Journal of Solids & Structures, 1993, 30(5): 695-723. [8] XIA L, WANG T C, SHIH C F. Higher-order analysis of crack tip fields in elastic power-law hardening materials[J]. Journal of the Mechanics and Physics of Solids, 1993, 41(4): 665-687. doi: 10.1016/0022-5096(93)90022-8 [9] YUAN F G, YANG S. Crack-tip fields in elastic-plastic material under plane stress mode Ⅰ loading[J]. International Journal of Fracture, 1997, 85(2): 131-155. doi: 10.1023/A:1007361116709 [10] YANG S, CHAO Y J, SUTTON M A. Higher order asymptotic crack tip fields in a power-law hardening material[J]. Engineering Fracture Mechanics, 1993, 45(1): 1-20. doi: 10.1016/0013-7944(93)90002-A [11] CHAO Y J, YANG S. Higher order crack tip fields and its implication for fracture of solids under mode Ⅱ conditions[J]. Engineering Fracture Mechanics, 1996, 55(5): 777-794. doi: 10.1016/0013-7944(96)00054-9 [12] RICE J R. Stresses due to a sharp notch in a work-hardening elastic-plastic material loaded by longitudinal shear[J]. Journal of Applied Mechanics, 1967, 34(2): 287. doi: 10.1115/1.3607681 [13] AMAZIGO J C. Fully plastic crack in an infinite body under anti-plane shear[J]. International Journal of Solids and Structures, 1974, 10(9): 1003-1015. doi: 10.1016/0020-7683(74)90008-0 [14] YANG S, YUAN F G, CAI X. Higher orderasymptotic elastic-plastic crack-tip fields under antiplane shear[J]. Engineering Fracture Mechanics, 1996, 54(3): 405-422. doi: 10.1016/0013-7944(95)00191-3 [15] YANG S, YUAN F G, CHIANG M Y M. Analytical forms of higher-order asymptotic elastic-plastic crack-tip fields in a linear hardening material under antiplane shear[J]. International Journal of Fracture, 1996, 80(1): 59-71. doi: 10.1007/BF00036480 [16] YUAN F G, YANG S. Analytical solutions of fully plastic crack-tip higher order fields under antiplane shear[J]. International Journal of Fracture, 1994, 69(1): 1-26. [17] WANG T J, KUANG Z B. Higher order asymptotic solutions of V-notch tip fields for damaged nonlinear materials under antiplane shear loading[J]. International Journal of Fracture, 1999, 96(4): 303-329. doi: 10.1023/A:1018657316810 [18] ZAPPALORTO M, LAZZARIN P. Analytical study of the elastic-plastic stress fields ahead of parabolic notches under antiplane shear loading[J]. International Journal of Fracture, 2007, 148(2): 139-154. doi: 10.1007/s10704-008-9185-7 [19] LAZZARIN P, ZAPPALORTO M. Plastic notch stress intensity factors for pointed V-notches under antiplane shear loading[J]. International Journal of Fracture, 2008, 152(1): 1-25. doi: 10.1007/s10704-008-9260-0 [20] ZAPPALORTO M, LAZZARIN P. A unified approach to the analysis of nonlinear stress and strain fields ahead of mode Ⅲ-loaded notches and cracks[J]. International Journal of Solids and Structures, 2010, 47(6): 851-864. doi: 10.1016/j.ijsolstr.2009.11.021 [21] ARAVAS N, BLAZO D H. Higher order terms in asymptotic elastoplastic mode Ⅲ crack tip solutions[J]. Acta Mechanica, 1991, 90(1/4): 139-153. [22] LOGHIN A, ZHANG N, JOSEPH P F. A nonlinear finite element eigenanalysis of antiplane shear including higher order terms[J]. Engineering Fracture Mechanics, 2000, 66(5): 441-454. doi: 10.1016/S0013-7944(00)00031-X [23] ZHANG N, JOSEPH P F. A nonlinear finite element eigenanalysis of singular stress fields in bimaterial wedges for plane strain[J]. International Journal of Fracture, 1998, 94(3): 299-319. [24] LOGHIN A, JOSEPH P F. Asymptotic solutions for mixed mode loading of cracks and wedges in power law hardening materials[J]. Engineering Fracture Mechanics, 2001, 68(14): 1511-1534. doi: 10.1016/S0013-7944(01)00050-9 [25] PATWARDHAN P A, NALAVDE R A, KUJAWSKI D. An estimation of Ramberg-Osgood constants for materials with and without Loder’s strain using yield and ultimate strengths[J]. Procedia Structure Integrity, 2019, 17: 750-757. doi: 10.1016/j.prostr.2019.08.100 [26] NIU Z R, GE D L, CHENG C Z, et al. Evaluation of the stress singularities of plane V-notches in bonded dissimilar materials[J]. Applied Mathematical Modelling, 2009, 33(3): 1776-1792. doi: 10.1016/j.apm.2008.03.007 -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号