Software Development for Stand Seam Roof Systems Based on the LiToSim Platform

-

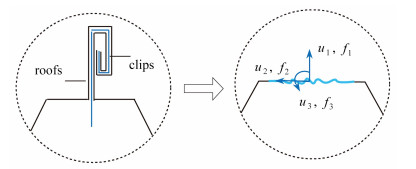

摘要: 直立咬合金属围护结构在风荷载作用下易发生风揭破坏,目前缺少能数值模拟金属围护结构的等效节点模型以及有限元分析软件.该文首先根据围护结构的非线性风致响应提出了直立咬合金属围护结构的弹塑性等效弹簧节点模型,并推导出了弹塑性等效弹簧单元的有限元算法;然后将算法嵌入平台LiToSim中,研发出了金属围护结构的定制化软件LiToSpr;最后建模分析了结构响应,并与抗风揭实验对比,验证了定制化软件LiToSpr的适用性.软件LiToSpr能够模拟直立咬合金属围护结构的非线性风致响应,为工程设计提供一定参考.Abstract: The stand seam roof is prone to failure under wind pressure. There is a lack of mechanical models and finite element analysis software that can numerically simulate the wind-induced response of stand seam roof systems. Firstly, the elastoplastic equivalent spring model for the stand seam roof was proposed according to the nonlinear wind-induced response of the structure, and the finite element algorithm for the elastoplastic equivalent spring element was derived, then the algorithm was embedded in the LiToSim platform to develop customized software LiToSpr for the stand seam roof. Finally, the structural responses were modeled, analyzed and compared with the anti-wind unmasking experiment results, to verify the applicability of customized software LiToSpr. The research indicates that, software LiToSpr can well simulate the wind-induced responses of the stand seam roof, and provides a reference for engineering design.

-

Key words:

- customized software /

- elastoplastic equivalent spring model /

- LiToSim platform /

- stand seam roof

edited-byedited-by1) (我刊编委冯志强来稿) -

表 1 部件材料参数

Table 1. Material parameters of the components

elasticity modulus E/MPa Poisson’s ratio μ thickness t/mm density ρ/(g/cm3) roof sheathing 2.34E+5 0.3 0.76 7.85 purline 6.97E+4 0.33 3 2.71 表 2 弹塑性等效弹簧节点模型的弹塑性参数

Table 2. The parameter values of the spring model

parameter a0 a1 m b1 b2 γ1 γ2 KV KX Kθ value 1 500 11 302 0.50 5.96 0.43 5.05 4.80 1 720 0.6 130 -

[1] 蔡昭昀. 我国金属屋面工程现状和发展趋势[J]. 中国建筑防水, 2010, 207(22): 34-38. https://www.cnki.com.cn/Article/CJFDTOTAL-ZGJF201022010.htmCAI Zhaoyun. Current situation and development trend of metal roofing engineering in China[J]. Waterproofing for Chinese Buildings, 2010, 207(22): 34-38. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-ZGJF201022010.htm [2] 黄唯, 吴耀华. 金属屋面在我国工程应用中存在的主要问题及分析[J]. 工业建筑, 2013, 43(6): 150-156. https://www.cnki.com.cn/Article/CJFDTOTAL-GYJZ201306035.htmHUANG Wei, WU Yaohua. The main existing problems and analysis of engineering applications for metal roofing in China[J]. Industrial Construction, 2013, 43(6): 150-156. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-GYJZ201306035.htm [3] 徐盛革. 浅析金属屋面系统的应用及发展[J]. 安徽建筑, 2013, 20(5): 96-97. https://www.cnki.com.cn/Article/CJFDTOTAL-AHJZ201305049.htmXU Shengge. Application and development of metal roofing system[J]. Anhui Architecture, 2013, 20(5): 96-97. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-AHJZ201305049.htm [4] MANSOUR K, LASZLO D. Purlin-cladding interaction in standing seam roofs[J]. Periodica Polytechnica Civil Engineering, 2012, 56(1): 13-23. doi: 10.3311/pp.ci.2012-1.02 [5] STEVEN F, GREGORY A K, DAVID S. Wind tunnel and uniform pressure tests of a standing seam metal roof model[J]. Journal of Structural Engineering, 2005, 131(4): 650-659. doi: 10.1061/(ASCE)0733-9445(2005)131:4(650) [6] 于敬海, 李路川, 盖力, 等. 直立锁边金属屋面系统抗风承载力节点试验研究[J]. 建筑结构, 2015, 45(17): 83-86. https://www.cnki.com.cn/Article/CJFDTOTAL-JCJG201517019.htmYU Jinghai, LI Luchuan, GAI Li, et al. Node test study on wind resistance bearing capacity of the standing seam metal roof system[J]. Building Structure, 2015, 45(17): 83-86. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-JCJG201517019.htm [7] BASKARAN B, KO STEVEN K P, MOLLETI S. A novel approach to estimate the wind uplift resistance of roofing systems[J]. Building and Environment, 2006, 44: 723-735. [8] 李松阳. 直立锁边金属屋面系统抗风性能的参数研究[D]. 武汉: 湖北工业大学, 2021.LI Songyang. Parameter study on wind resistant performance of standing seam metal roof system[D]. Wuhan: Hubei University of Technology, 2021. (in Chinese) [9] EL DAMATTY A A, RAHMAN M, RAGHEB O. Component testing and finite element modeling of standing seam roofs[J]. Thin-Walled Structures, 2003, 41(11): 1053-1072. doi: 10.1016/S0263-8231(03)00048-X [10] ALI H M, SENSENY P E. Models for standing seam roofs[J]. Journal of Wind Engineering & Industrial Aerodynamics, 2003, 91(12): 1689-1702. [11] WU D, SUN Y, WU Y. Wind loading and wind effects on the roof of Harbin west railway station[J]. Advanced Materials Research, 2010, 163: 163-167. [12] WU T, SUN Y, CAO Z. A new recommended load cycle for dynamic wind-resistant test of roof system based on the principle of damage equivalence[J]. Journal of Building Engineering, 2022, 48: 103911. doi: 10.1016/j.jobe.2021.103911 [13] SUN Y, WU T, CAO Z. Wind vulnerability analysis of standing seam roof system with consideration of multistage performance levels[J]. Thin-Walled Structures, 2021, 165: 107942. doi: 10.1016/j.tws.2021.107942 [14] 陈玉. 直立锁边屋面系统抗风承载能力研究[D]. 北京: 北京交通大学, 2015.CHEN Yu. Loading bearing capacity of the standing seam roof system under the wind load[D]. Beijing: Beijing Jiaotong University, 2015. (in Chinese) [15] 景晓昆, 李元齐. 直立锁缝屋面体系固定支座的有效静力风荷载[J]. 同济大学学报(自然科学版), 2013, 41(11): 1630-1635. https://www.cnki.com.cn/Article/CJFDTOTAL-TJDZ201311004.htmJING Xiaokun, LI Yuanqi. Effective static wind load for clips of standing seam roof system[J]. Journal of Tongji University(Natural Science Edition), 2013, 41(11): 1630-1635. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-TJDZ201311004.htm [16] 周济. 智能制造是"中国制造2025"主攻方向[J]. 企业观察家, 2019(11): 54-55. https://www.cnki.com.cn/Article/CJFDTOTAL-QYGC201911018.htmZHOU Ji. Intelligent manufacturing is the main direction of "Made in China 2025"[J]. Enterprise Observer, 2019(11): 54-55. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-QYGC201911018.htm [17] 王彬文, 段世慧, 聂小华. 航空结构分析CAE软件发展现状与未来挑战[J]. 航空学报, 2022, 43(6): 28-51. https://www.cnki.com.cn/Article/CJFDTOTAL-HKXB202206002.htmWANG Binwen, DUAN Shihui, NIE Xiaohua. Development situation and future challenges of CAE software used in aeronautical structural analysis[J]. Journal of Aeronautics, 2022, 43(6): 28-51. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-HKXB202206002.htm [18] 周洋靖. 基于双势理论的多重非线性精细算法的研究及金属成形软件开发[D]. 成都: 西南交通大学, 2019.ZHOU Yangjing. Research of multi-nonlinear precise algorithm based on bi-potential theory and metal forming software development[D]. Chengdu: Southwest Jiaotong University, 2019. (in Chinese) [19] PENG L, FENG Z, JOLI P. LiToTac: an interactive-interface software for finite element analysis of multiple contact dynamics[J]. Computer Modeling in Engineering & Sciences, 2019, 118(1): 111-137. [20] 陈焕星, 赵星华, 丘建中. 大型通用有限元结构分析程序系统HAJIF(X)[J]. 航空计算技术, 1998, 28(1): 22-25. https://www.cnki.com.cn/Article/CJFDTOTAL-HKJJ199801007.htmCHEN Huanxing, ZHAO Xinghua, QIU Jianzhong. Large scale general purpose finite element program system for structural analysis for structural analysis[J]. Aeronautical Computing Technology, 1998, 28(1): 22-25. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-HKJJ199801007.htm [21] 唐滨, 李宝君. FastCAE: 国产CAE仿真软件研发支撑平台[C]//第十四届中国CAE工程分析技术年会论文集. 银川, 中国, 2018.TANG Bin, LI Baojun. FastCAE: domestic CAE simulation software R&D support platform[C]//Proceedings of the 14th China CAE Engineering Analysis Technology Annual Conference. Yinchuan, China, 2018. (in Chinese) [22] 彭鸿博, 张宏建. 金属材料本构模型的研究进展[J]. 机械工程材料, 2012, 36(3): 5-10. https://www.cnki.com.cn/Article/CJFDTOTAL-GXGC201307002.htmPENG Hongbo, ZHANG Hongjian. Research development of the constitutive models of metal materials[J]. Materials for Mechanical Engineering, 2012, 36(3): 5-10. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-GXGC201307002.htm [23] 曾祥国, 陈华燕, 胡益平. 工程弹塑性力学[M]. 成都: 四川大学出版社, 2013: 254.ZENG Xiangguo, CHEN Huayan, HU Yiping. Engineering Elastoplastic Mechanics[M]. Chengdu: Sichuan University Press, 2013: 254. (in Chinese) [24] 李正良, 王成, 王涛, 等. 基于主动学习Kriging模型的直立锁缝屋面系统抗风揭可靠度分析[J]. 工程力学, 2022, 39(10): 111-119. https://www.cnki.com.cn/Article/CJFDTOTAL-GCLX202210011.htmLI Zhengliang, WANG Cheng, WANG Tao, et al. Reliability analysis of wind-resistance of standing seam roof system based on active learning Kriging model[J]. Engineering Mechanics, 2022, 39(10): 111-119. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-GCLX202210011.htm [25] 康国政. 非弹性本构理论及其有限元实现[M]. 成都: 西南交通大学, 2010: 20-40.KANG Guozheng. Inelastic Constitutive Theory and Its Finite Element Implementation[M]. Chengdu: Southwest Jiaotong University, 2010: 20-40. (in Chinese) [26] 彭梦瑶, 顾水涛, 周洋靖, 等. 基于LiToSim平台的疲劳寿命评估LtsFatigue软件开发及应用[J]. 应用数学和力学, 2022, 43(9): 976-986. doi: 10.21656/1000-0887.420277PENG Mengyao, GU Shuitao, ZHOU Yangjing, et al. Development and application of fatigue life evaluation software LtsFatigue based on LiToSim[J]. Applied Mathematics and Mechanics, 2022, 43(9): 976-986. (in Chinese) doi: 10.21656/1000-0887.420277 [27] 叶彦鹏, 顾水涛, 刘敏, 等. 基于LiToSim平台的海上风机过渡段优化软件开发[J]. 应用数学和力学, 2021, 42(5): 441-451. doi: 10.21656/1000-0887.410354YE Yanpeng, GU Shuitao, LIU Min, et al. Optimization software development for offshore turbine transition structures based on LiToSim[J]. Applied Mathematics and Mechanics, 2021, 42(5): 441-451. (in Chinese) doi: 10.21656/1000-0887.410354 [28] EL DAMATTY A A, RAHMAN M. Testing and analysis for non-linear behaviour of standing seam roof[C]//Fourth International Conference on Thin-Walled Structures. Loughborough, 2004: 347-354. -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号