Characteristic Analysis on Effects of High-Energy Pipe Wall Friction on Steam Jets

-

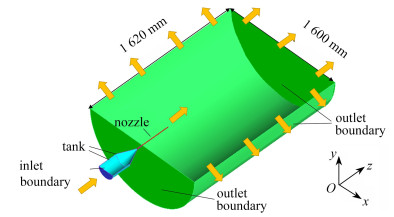

摘要: 以双端断裂后的高能管道为研究对象,对蒸汽射流过程进行了数值模拟. 研究了滞止压力、管道壁面摩擦对喷射锥和射流冲击力的影响,总结了喷射锥内速度、温度、压力的规律. 并将不同入口条件下的射流冲击力与使用设计准则计算结果进行了比较,探究了设计准则在超出适用压力范围时,有关公式和方法的适用性. 模拟结果表明,蒸汽射流在出破口平面后一段距离内,压力和温度迅速下降,速度迅速上升,随后均有波动变化,最终随着逐渐远离喷嘴出口,速度、温度逐渐下降,压力趋近于大气压. 喷射锥初始扩散角度、射流影响范围及射流冲击力与入口压力正相关,与喷管壁面粗糙度负相关. 设计准则对射流初始扩散角度的假设不具有普遍性,当压力较大时,实际射流初始扩散角度大于规范规定的45°. 设计准则评定冲击射流全部喷射到平板的冲击效应时,标准对于理想无摩擦的管道喷射冲击力可以精准预测,但使用标准对实际有壁面摩擦的管道射流冲击力进行评估时,会存在一定偏差,且随着壁面粗糙度和压力的增加,评估偏差程度会增大.Abstract: The steam jetting during the double-end fracture of high-energy pipelines was studied through numerical simulations. The effects of stagnation pressure and pipe wall friction on the jet cone and impingement forces were investigated, and the patterns of velocity, temperature, and pressure in the jet cone were summarized. Additionally, by comparison of the impingement forces under various inlet conditions with the results calculated based on the design criteria, the applicability of the design criteria beyond the applicable pressure range was studied. The results show that, the pressure and temperature of the steam jet decrease rapidly within a certain distance from the nozzle outlet, while the velocity rapidly increases, followed by fluctuations and changes. As the distance from the nozzle outlet increases, the velocity and temperature in the jet cone gradually decrease, and the pressure is close to the atmospheric pressure. The initial spread angle of the jet cone, the influence zone of the jet cone, and the impingement force are positively correlated with the inlet pressure, and negatively correlated with the roughness of the inner wall of the nozzle. The assumption of the initial jet cone angle in the design criteria is not universal, and the actual initial jet cone angle exceeds 45° set by the standard model at higher stagnation pressures. In the case where the whole jet impinges on the flat plate, according to the design criteria, the standard model can precisely predict the impingement force of the steam jet in the ideal pipe without wall friction. However, under the design criteria, there will be some deviation to evaluate the impingement force on a real pipe jet with wall friction, and this deviation will increase with wall friction and pressure.

-

Key words:

- igh-energy pipeline /

- steam jet /

- wall friction /

- impingement force

-

表 1 不同条件下圆盘所受喷射冲击力(单位: N)

Table 1. Jet impingement forces on the disk under different conditions (unit: N)

6.90 MPa 13.80 MPa 20.00 MPa predicted value 430.67 867.68 1 260.36 Δ=0.000 0 mm 419.67 859.16 1 251.19 Δ=0.012 5 mm 368.63 751.59 1 091.79 Δ=0.025 0 mm 358.03 726.69 1 055.70 Δ=0.125 0 mm 323.54 652.03 948.35 -

[1] 郭城. 核电站主给水管道破裂事故的运行研究[J]. 核科学与工程, 2011, 31(3): 274-280.GUO Cheng. The operation study of main water supply pipe rupture accident at nuclear power plant[J]. Chinese Journal of Nuclear Science and Engineering, 2011, 31(3): 274-280. (in Chinese) [2] KONG R, KIM S, ISHⅡ M. Review of jet impingement in high-energy piping systems[J]. Nuclear Engineering and Design, 2020, 357: 110411. doi: 10.1016/j.nucengdes.2019.110411 [3] 冯志鹏, 张毅雄, 臧峰刚. 直管束流固耦合振动的数值模拟[J]. 应用数学和力学, 2013, 34(11): 1165-1172. doi: 10.3879/j.issn.1000-0887.2013.11.006FENG Zhipeng, ZHANG Yixiong, ZANG Fenggang. Numerical simulation of fluid-structure interaction for tube bundles[J]. Applied Mathematics and Mechanics, 2013, 34(11): 1165-1172. (in Chinese) doi: 10.3879/j.issn.1000-0887.2013.11.006 [4] 黄甲, 彭建, 吴高峰, 等. 核电厂高能管道破裂喷射冲击影响区域的分析[J]. 科技创新与应用, 2019, 9(31): 68-72.HUANG Jia, PENG Jian, WU Gaofeng, et al. Calculation and analysis of jet impingement influence zone of high energy pipe break in nuclear power station[J]. Technology Innovation and Application, 2019, 9(31): 68-72. (in Chinese) [5] MIYATAKE O, TOMIMURA T, IDE Y, et al. Effect of liquid temperature on spray flash evaporation[J]. Desalination, 1981, 37(3): 351-366. doi: 10.1016/S0011-9164(00)88658-0 [6] CHEN Q, KUMJA M, LI Y, et al. Experimental and mathematical study of the spray flash evaporation phenomena[J]. Applied Thermal Engineering, 2018, 130: 598-610. doi: 10.1016/j.applthermaleng.2017.11.018 [7] QUDDUS A, SHAH A, QURESHI K R, et al. Study of steam jet characteristics and regime maps for bevelled spray nozzles exhausting into quiescent water[J]. International Journal of Heat and Mass Transfer, 2022, 190: 122780. doi: 10.1016/j.ijheatmasstransfer.2022.122780 [8] FU P F, ZHAO Q B, LIU JP, et al. Experimental and theoretical study on the association between entrainment vortex evolution and pressure oscillation of steam jet condensation[J]. Experimental Thermal and Fluid Science, 2023, 141: 110797. doi: 10.1016/j.expthermflusci.2022.110797 [9] KITADE K, NAKATOGAWA T, NISHIKAWA H, et al. Experimental study of pipe reaction force and jet impingement load at the pipe break[C]// 5 th SMIRT Conference. Berlin, 1979. [10] MASUDA F, NAKATOGAWA T, KAWANISHI K, et al. Experimental study on an impingement high-pressure steam jet[J]. Nuclear Engineering and Design, 1982, 67(2): 273-286. doi: 10.1016/0029-5493(82)90146-7 [11] FORREST C F, SHIN K S, MIDVIDY W I, et al. Measurements of impact loads and expansion of flashing water jets[J]. Nuclear Engineering and Design, 1987, 99: 53-61. doi: 10.1016/0029-5493(87)90107-5 [12] YANO T, ISOZAKI T, UEDA S, et al. An experimental study of blowdown thrust and jet forces for a pipe under boiling water reactor loss-of-coolant accident conditions[J]. Nuclear Science and Engineering, 1984, 88(3): 386-395. doi: 10.13182/NSE84-A18592 [13] 孙得川, 胡春波, 蔡体敏. 带有横向射流的三维超声速湍流流场分析[J]. 应用数学和力学, 2002, 23(1): 99-105. http://www.applmathmech.cn/article/id/1853SUN Dechuan, HU Chunbo, CAI Timin. Computation of supersonic turbulent flowfield with transverse injection[J]. Applied Mathematics and Mechanics, 2002, 23(1): 99-105. (in Chinese) http://www.applmathmech.cn/article/id/1853 [14] 冉令可, 杨海华, 张星辰, 等. 锯齿射流与圆射流流场和远场噪声特性的对比研究[J]. 应用数学和力学, 2016, 37(12): 1255-1271. doi: 10.21656/1000-0887.370507RAN Lingke, YANG Haihua, ZHANG Xingchen, et al. Investigation of flow development and noise generation of free and chevron jets[J]. Applied Mathematics and Mechanics, 2016, 37(12): 1255-1271. (in Chinese) doi: 10.21656/1000-0887.370507 [15] 吕元伟, 赵韫铎, 张靖周, 等. 冠齿脉冲射流冲击平直靶板对流换热实验[J]. 航空动力学报, 2023, 38(4): 787-794.LÜ Yuanwei, ZHAO Yunduo, ZHANG Jingzhou, et al. Experiment on convective heat transfer of pulsed chevron jet impingement on flat plate[J]. Journal of Aerospace Power, 2023, 38(4): 787-794. (in Chinese) [16] YANG G Z, JIANG G C, QIU F C, et al. Numerical simulation of jet impact process with different jet velocities in a negative pressure ambient[J]. Chemical Engineering and Processing-Process Intensification, 2023, 193: 109547. [17] KASTNER W, RIPPEL R. Jet impingement forces on structures: experiments and empirical calculation methods[J]. Nuclear Engineering and Design, 1988, 105(3): 269-284. [18] XU Q, TAKAHASHI S, TAKAMURA N, et al. Evaluation of jet impact region and fluid force generated from ruptured pipes 3: evaluation of established standards[C]//Volume 3 : Thermal-Hydraulics. Charlotte, North Carolina: American Society of Mechanical Engineers, 2016: V003T09A016. [19] MORITA R, UCHIYAMA Y, WATANABE S, et al. Evaluation of jet impact region and fluid force generated from ruptured pipes 1: numerical and experimental evaluation of affected region by steam jet[C]//Volume 3 : Thermal-Hydraulics. Charlotte, North Carolina: American Society of Mechanical Engineers, 2016: V003T09A019. [20] TAKAHASHI S, XU Q, TAKAMURA N, et al. Evaluation of jet impact region and fluid force generated from ruptured pipes 2: evaluation of fluid force using computational fluid dynamics analysis[C]//Volume 3 : Thermal-Hydraulics. Charlotte, North Carolina: American Society of Mechanical Engineers, 2016: V003T09A015. [21] 彭建, 张涛, 毕勤成, 等. 高能管道断裂蒸汽喷射过程数值模拟[J]. 热科学与技术, 2022, 21(4): 383-389.PENG Jian, ZHANG Tao, BI Qincheng, et al. Numerical simulation of steam injection process during high-energy-pipeline fracture[J]. Journal of Thermal Science and Technology, 2022, 21(4): 383-389. (in Chinese) [22] 王迎, 李勇, 贺艳秋, 等. 粗糙度与破口尺寸对管道裂纹摩擦系数影响的计算研究[J]. 装备制造技术, 2016(3): 38-41.WANG Ying, LI Yong, HE Yanqiu, et al. Numerical study of effect with roughness and crack opening displacement on friction coefficient of crack[J]. Equipment Manufacturing Technology, 2016(3): 38-41. (in Chinese) [23] XU P, SASMITO A P, QIU S X, et al. Heat transfer and entropy generation in air jet impingement on a model rough surface[J]. International Communications in Heat and Mass Transfer, 2016, 72: 48-56. [24] 轻水堆核电厂假想管道破损事故防护设计准则: EJ/T 335—1998[S]. 1998.Design basis for protection of light water nuclear power plants against the effects of postulated pipe rupture: EJ/T 335—1998[S]. 1998. (in Chinese) [25] BASKAYA S, GILCHRIST A, FRASER S M. The radial spread and axial decay of temperature in turbulent condensing jets[J]. International Communications in Heat and Mass Transfer, 1997, 24(4): 465-474. [26] HEYERICHS K, POLLARD A. Heat transfer in separated and impinging turbulent flows[J]. International Journal of Heat and Mass Transfer, 1996, 39(12): 2385-2400. [27] 玉城怜士, 山川胜史. 电弧喷涂的喷嘴射流研究[J]. 应用数学和力学, 2016, 37(12): 1394-1402. doi: 10.21656/1000-0887.370554TAMAKI R, YAMAKAWA M. Study on the nozzle jet in arc spraying[J]. Applied Mathematics and Mechanics, 2016, 37(12): 1394-1402. (in Chinese) doi: 10.21656/1000-0887.370554 [28] GUO H, NOCIVELLI L, TORELLI R, et al. Towards understanding the development and characteristics of under-expanded flash boiling jets[J]. International Journal of Multiphase Flow, 2020, 129: 103315. [29] FRANQUET E, PERRIER V, GIBOUT S, et al. Freeunderexpanded jets in a quiescent medium: a review[J]. Progress in Aerospace Sciences, 2015, 77: 25-53. [30] KONG R, KIM S, ISHⅡ M. Jet impingement in high-energy piping systems, part Ⅰ: characteristics and model evaluation[J]. Progress in Nuclear Energy, 2021, 142: 104002. -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号