Evaluation of BP Neural Network Algorithms for Predicting Elastic Buckling Loads on Cold-Formed Steel Components

-

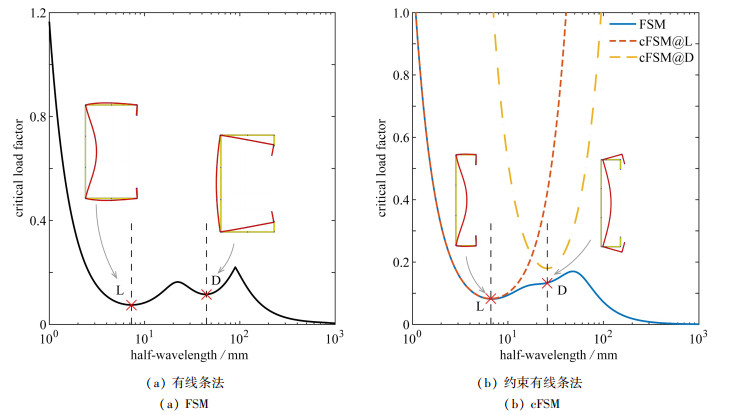

摘要: 弹性屈曲临界荷载是准确评价冷弯型钢构件承载力的重要指标. 利用人工神经网络(artificial neural networks, ANNs)模型对冷弯C型截面轴压构件的屈曲临界载荷进行了预测,将影响屈曲的几何参数和有限条法所得的计算结果作为数据集,对神经网络模型进行了训练、验证和测试. 基于最优化理论,采用6种不同的优化算法进行了模型的训练,并比较了不同算法的网络模型性能. 通过随机网格搜索确定最优超参数,使用3种统计参数来评估训练后的人工神经网络的性能,以得到最适合预测屈曲临界荷载的神经网络模型. 结果表明:Levenberg-Marquardt(L-M)算法在非线性最小二乘问题上相较于其他算法具有更高的准确性,多次训练后,L-M算法使模型预测误差非常小,而其他算法在准确度上不及L-M算法.Abstract: The elastic buckling critical load is a crucial indicator for accurately assessing the load-bearing capacity of cold-formed steel components. The artificial neural networks were used to predict the buckling loads on cold-formed flanged steel columns, with geometric parameters and finite strip method results as the dataset. Six optimization algorithms based on the optimization theory were applied to train the networks, with their performances compared. Optimal hyperparameters were determined through random grid search. Three statistical parameters were used to evaluate the networks' post-training performances. The Levenberg-Marquardt (L-M) algorithm demonstrates higher accuracy in nonlinear least squares problems, significantly reducing prediction errors after multiple trainings, and outperforming other algorithms.

-

表 1 冷弯型C型截面尺寸范围(单位: mm)

Table 1. Ranges of sectional dimensions of cold-formed lipped channel steels (unit: mm)

component min max Hc 41.15 406.40 Bc 31.75 88.90 Dc 4.78 25.40 t 0.48 3.15 表 2 各训练算法运行时长

Table 2. Runtime lengths of various training algorithms

training algorithm average time/s ratio min time/s max time/s GDX 1.29 1.00 1.16 1.41 GDM 3.93 3.05 0.32 4.18 GD 4.13 3.21 4.10 4.19 SCG 9.36 7.27 7.81 37.75 BFG 24.80 19.26 16.93 167.68 L-M 132.10 102.62 110.54 135.84 表 3 各训练算法验证集误差

Table 3. Validation set errors for various training algorithms

training algorithm average MSE ratio min MSE max MSE L-M 2.01E4 1.00 1.67E4 2.56E4 BFG 4.48E4 2.16 3.89E4 5.74E4 SCG 5.69E4 2.74 4.95E4 6.74E4 GDX 8.73E3 42.10 6.20E3 1.30E2 GD 8.67E2 417.85 6.92E2 1.16E1 GDM 8.99E2 433.52 5.09E2 2.02E1 表 4 BFG和SCG训练算法时长对比

Table 4. Comparison of training durations between BFG and SCG algorithms

training algorithm average time/s ratio min time/s max time/s BFG 40.23 1.00 22.46 64.90 SCG 45.27 1.13 19.40 208.06 L-M 363.35 9.03 107.76 1 359.262 表 5 BFG和SCG验证集MSE对比

Table 5. Comparison of validation set MSE between BFG and SCG algorithms

training algorithm average MSE ratio min MSE max MSE BFG 3.40E4 1.00 2.40E4 8.6E4 SCG 3.40E4 1.00 2.70E4 4.5E4 L-M 1.95E4 0.57 1.68E4 2.33E4 表 6 BFG和SCG epoch对比

Table 6. Comparison of epochs between BFG and SCG algorithms

training algorithm average epoch ratio min epoch max epoch BFG 1 191.90 1.00 657 1 957 SCG 2 358.55 1.98 1 247 4 185 L-M 1 344.75 1.13 394 5 000 -

[1] VON KÁRMÁN T, SECHLER E E, DONNELL L H. The strength of thin plates in compression[J]. Journal of Fluids Engineering, 1932, 54(2): 53-56. [2] 杨梦欢. 冷弯薄壁卷边槽钢受压柱畸变屈曲性能的研究[D]. 武汉: 武汉理工大学, 2013.YANG Menghuan. Distortional buckling behavior of cold-formed thin-wall steel lipped channel columns under compression[D]. Wuhan: Wuhan University of Technology, 2013. (in Chinese) [3] 高段. 冷弯薄壁卷边槽钢受弯构件畸变屈曲性能研究[D]. 武汉: 武汉理工大学, 2013.GAO Duan. Study on distortional buckling of cold-formed thin-walled lipped channel steel in bending[D]. Wuhan: Wuhan University of Technology, 2013. (in Chinese) [4] 陈骥. 冷弯薄壁型钢构件的直接强度设计法[J]. 建筑钢结构进展, 2003, 5(4): 5-13.CHEN Ji. Direct strength method for the design of cold-formed lipped channel members[J]. Progress in Steel Building Structures, 2003, 5(4): 5-13. (in Chinese) [5] CHEUNG Y, THAM L. Finite Strip Method[M]. CRC Press, 1997. [6] LI Z, SCHAFER B W. Buckling analysis of cold-formed steel members with general boundary conditions using CUFSM conventional and constrained finite strip methods[C]// 20 th International Specialty Conference on Cold-Formed Steel Structures. St Louis, Missouri, 2010. [7] ÁDÁNY S, SCHAFER B W. Buckling mode decomposition of single-branched open cross-section members via finite strip method: derivation[J]. Thin-Walled Structures, 2006, 44(5): 563-584. doi: 10.1016/j.tws.2006.03.013 [8] UNGUREANU V, DUBINA D. Recent research advances on ECBL approach, part Ⅰ: plastic-elastic interactive buckling of cold-formed steel sections[J]. Thin-Walled Structures, 2004, 42(2): 177-194. doi: 10.1016/S0263-8231(03)00056-9 [9] DAVIES J M. Recent research advances in cold-formed steel structures[J]. Journal of Constructional Steel Research, 2000, 55(1/2/3): 267-288. [10] WANG T, ZHA Z, PAN C. Prediction for elastic local buckling stress and ultimate strength of H-section beam[J]. Heliyon, 2023, 9(4): e14700. doi: 10.1016/j.heliyon.2023.e14700 [11] ZARRINGOL M, THAI H T, THAI S, et al. Application of ANN to the design of CFST columns[J]. Structures, 2020, 28: 2203-2220. doi: 10.1016/j.istruc.2020.10.048 [12] WU T Y, EL-TAWIL S, MCCORMICK J. Effect of cyclic flange local buckling on the capacity of steel members[J]. Engineering Structures, 2019, 200: 109705. doi: 10.1016/j.engstruct.2019.109705 [13] PITTON S F, RICCI S, BISAGNI C. Buckling optimization of variable stiffness cylindrical shells through artificial intelligence techniques[J]. Composite Structures, 2019, 230: 111513. doi: 10.1016/j.compstruct.2019.111513 [14] TOHIDI S, SHARIFI Y. Neural networks for inelastic distortional buckling capacity assessment of steel Ⅰ-beams[J]. Thin-Walled Structures, 2015, 94: 359-371. doi: 10.1016/j.tws.2015.04.023 [15] 张广江, 杨德泽, 楚锡华. 基于人工神经网络的颗粒材料本构关系及边值问题研究[J]. 应用数学和力学, 2024, 45(2): 155-166. doi: 10.21656/1000-0887.440248ZHANG Guangjiang, YANG Deze, CHU Xihua. Study on constitutive relations and boundary value problems of granular materials based on artificial neural networks[J]. Applied Mathematics and Mechanics, 2024, 45(2): 155-166. (in Chinese) doi: 10.21656/1000-0887.440248 [16] KAVEH A, BAKHSHPOORI T, HAMZE-ZIABARI S M. GMDH-based prediction of shear strength of FRP-RC beams with and without stirrups[J]. Computers and Concrete, 2018, 22(2): 197-207. [17] KAVEH A, ELMIEH R, SERVATI H. Prediction of moment-rotation characteristic for semi-rigid connections using BP neural networks[C]//Computational Engineering Using Metaphors From Nature, 2001: 15-24. [18] IRANMANESH A, KAVEH A. Structural optimization by gradient-based neural networks[J]. International Journal for Numerical Methods in Engineering, 1999, 46(2): 297-311. doi: 10.1002/(SICI)1097-0207(19990920)46:2<297::AID-NME679>3.0.CO;2-C [19] KAVEH A, IRANMANESH A. Comparative study of back propagation and improved counter propagation neural nets in structural analysis and optimization[J]. International Journal of Space Structures, 1998, 13(4): 177-185. doi: 10.1177/026635119801300401 [20] MOJTABAEI S M, BECQUE J, HAJIRASOULIHA I, et al. Predicting the buckling behaviour of thin-walled structural elements using machine learning methods[J]. Thin-Walled Structures, 2023, 184: 110518. doi: 10.1016/j.tws.2022.110518 [21] WASZCZYSZYN Z, BARTCZAK M. Neural prediction of buckling loads of cylindrical shells with geometrical imperfections[J]. International Journal of Non-Linear Mechanics, 2002, 37(4/5): 763-775. [22] MARKOPOULOS A P, MANOLAKOS D E, VAXEVANIDIS N M. Prediction of the collapse modes of PVC cylindrical shells under compressive axial loads using artificial neural networks[C]//The International Federation for Information Processing. Boston, MA, 2007: 251-258. [23] PALA M. A new formulation for distortional buckling stress in cold-formed steel members[J]. Journal of Constructional Steel Research, 2006, 62(7): 716-722. [24] PALA M, CAGLAR N. A parametric study for distortional buckling stress on cold-formed steel using a neural network[J]. Journal of Constructional Steel Research, 2007, 63(5): 686-691. [25] GUZELBEY I H, CEVIK A, ERKLIG A. Prediction of web crippling strength of cold-formed steel sheetings using neural networks[J]. Journal of Constructional Steel Research, 2006, 62(10): 962-973. [26] DEGTYAREV V V. Neural networks for predicting shear strength of CFS channels with slotted webs[J]. Journal of Constructional Steel Research, 2021, 177: 106443. [27] DEGTYAREV V V, NASER M Z. Boosting machines for predicting shear strength of CFS channels with staggered web perforations[J]. Structures, 2021, 34: 3391-3403. [28] ÁDÁNY S, SCHAFER B W. A full modal decomposition of thin-walled, single-branched open cross-section membersvia the constrained finite strip method[J]. Journal of Constructional Steel Research, 2008, 64(1): 12-29. [29] NOORZAEI J, HAKIM S, JAAFAR M, et al. An optimal architecture of artificialneural network for predicting compressive strength of concrete[J]. Indian Concrete Journal, 2007, 81(8): 17-24. [30] FARZINPOUR A, DEHCHESHMEH E M, BROUJERDIAN V, et al. Efficient boosting-based algorithms for shear strength prediction of squat RC walls[J]. Case Studies in Construction Materials, 2023, 18: e01928. [31] BAI C, NGUYEN H, ASTERIS P G, et al. A refreshing view of soft computing models for predicting the deflection of reinforced concrete beams[J]. Applied Soft Computing, 2020, 97: 106831. http://www.zhangqiaokeyan.com/journal-foreign-detail/0704028534301.html [32] HAKIM S J S, PAKNAHAD M, KAMARUDIN A F, et al. Buckling prediction in steel columns: unveiling insights with artificial neural networks[J]. International Journal of Engineering Trends and Technology, 2023, 71(9): 322-330. [33] AHMAD A, COTSOVOS D M, LAGAROS N D. Assessing the reliability of RC code predictions through the use of artificial neural networks[C]//School of Energy, Geoscience, Infrastructure and SocietyInstitute for Infrastructure & Environment. 2016. [34] HAGAN M T, DEMUTH H B, BEALE M. Neural Network Design[M]. PWS Publishing Co, 1997. [35] The MathWorks[M]. Natick, MA: MATLAB, 2012. [36] DENNIS JR J E, SCHNABEL R B. Numerical Methods for Unconstrained Optimization and Nonlinear Equations[M]. SIAM, 1996. [37] MARQUARDT D W. An algorithm for least-squares estimation of nonlinear parameters[J]. Journal of the Society for Industrial and Applied Mathematics, 1963, 11(2): 431-441. [38] M∅LLER M F. A scaled conjugate gradient algorithm for fast supervised learning[J]. Neural Networks, 1993, 6(4): 525-533. [39] WORKS M. Statistics and Machine Learning Toolbox User's Guide[M]. Matwork Inc, 2017. -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号