| [1] |

SAYAM A, RAHMAN A N M M, RAHMAN M S, et al. A review on carbon fiber-reinforced hierarchical composites: mechanical performance, manufacturing process, structural applications and allied challenges[J]. Carbon Letters, 2022, 32 : 1173-1205. doi: 10.1007/s42823-022-00358-2

|

| [2] |

刘鑫, 吴倩倩, 于国财, 等. 碳纤维/树脂基复合材料曲壁蜂窝夹芯结构的三点弯曲性能[J]. 应用数学和力学, 2022, 43 (5): 490-498.LIU Xin, WU Qianqian, YU Guocai, et al. Three-point bending properties of carbon fiber reinforced polymer composite honeycomb sandwich structures with curved wall[J]. Applied Mathematics and Mechanics, 2022, 43 (5): 490-498. (in Chinese)

|

| [3] |

谢世红, 高洁, 宁来元, 等. 碳纤维/聚合物复合材料热导率近十年研究进展[J]. 复合材料学报, 2024, 41 (2): 561-571.XIE Shihong, GAO Jie, NING Laiyuan, et al. Research progress on thermal conductivity of carbon fiber/polymer composites in recent ten years[J]. Acta Materiae Compositae Sinica, 2024, 41 (2): 561-571. (in Chinese)

|

| [4] |

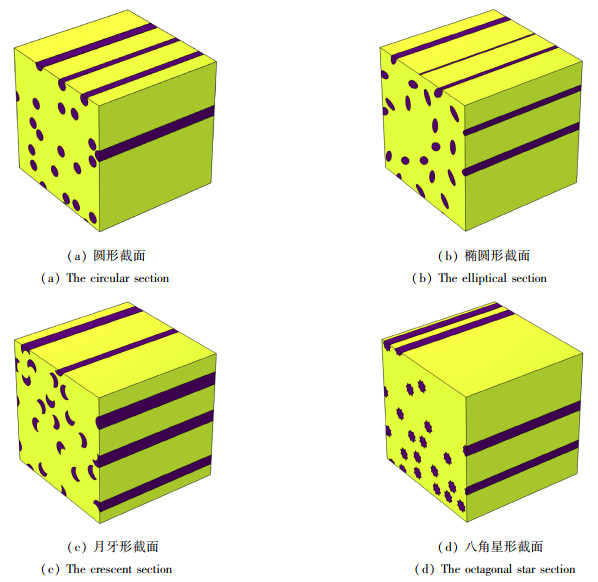

范春峰, 何鉴峰, 王建. 异形纤维及其制造技术进展[J]. 高分子材料科学与工程, 2024, 40 (3): 172-179.FAN Chunfeng, HE Jianfeng, WANG Jian. Progress in shaped fibers and their manufacturing techniques: a review[J]. Polymer Materials Science & Engineering, 2024, 40 (3): 172-179. (in Chinese)

|

| [5] |

王立超, 李响, 伊翠云, 等. 空天领域用3D打印纤维复合材料研究进展[J]. 纤维复合材料, 2023, 40 (4): 86-89.WANG Lichao, LI Xiang, YI Cuiyun, et al. Research progress of 3D printed fiber composites used in aerospace field[J]. Fiber Composites, 2023, 40 (4): 86-89. (in Chinese)

|

| [6] |

于敬晖. 碳纤维复合材料在汽车结构件中的应用研究进展[J]. 纤维复合材料, 2023, 40 (4): 71-75.YU Jinghui. Application research progress of CFRP in automobile structure parts[J]. Fiber Composites, 2023, 40 (4): 71-75. (in Chinese)

|

| [7] |

陈立军, 钟百敏, 胡泽旭, 等. 截面形状对聚酰胺6/石墨烯复合纤维性能的影响[J]. 合成纤维, 2019, 48 (7): 5-8.CHEN Lijun, ZHONG Baimin, HU Zexu, et al. Effect of cross-sectional morphology on properties of polyamide 6/graphene composite fiber[J]. Synthetic Fiber in China, 2019, 48 (7): 5-8. (in Chinese)

|

| [8] |

HE C W, GE J R, CAO X F, et al. The effects of fiber radius and fiber shape deviations and of matrix void content on the strengths and failure mechanisms of UD composites by computational micromechanics[J]. Composites Science and Technology, 2022, 218 : 109139.

|

| [9] |

BOND I, HUCKER M, WEAVER P, et al. Mechanical behaviour of circular and triangular glass fibres and their composites[J]. Composites Science and Technology, 2002, 62 (7/8): 1051-1061.

|

| [10] |

HUANG H W, HADIGHEH S A, BAGHAEI K A. Influences of fibre shape on the transverse modulus of unidirectional fibre reinforced composites using finite element and machine learning methods[J]. Composite Structures, 2023, 312 : 116872.

|

| [11] |

RAO B R, RAJU V R, RAO K M. Effect of fibre shape on transverse thermal conductivity of unidirectional composites[J]. Sadhana, 2015, 40 (2): 503-513.

|

| [12] |

PATHAN M V, TAGARIELLI V L, PATSIAS S. Effect of fibre shape and interphase on the anisotropic viscoelastic response of fibre composites[J]. Composite Structures, 2017, 162 : 156-163.

|

| [13] |

SADOWSKI P, KOWALCZYK-GAJEWSKA K, STUPKIEWICZ S. Classical estimates of the effective thermoelastic properties of copper-graphene composites[J]. Composites Part B: Engineering, 2015, 80 : 278-290.

|

| [14] |

HERRÁEZ M, GONZÁLEZ C, LOPES C S, et al. Computational micromechanics evaluation of the effect of fibre shape on the transverse strength of unidirectional composites: an approach to virtual materials design[J]. Composites Part A: Applied Science and Manufacturing, 2016, 91 : 484-492.

|

| [15] |

周磊, 刘玉库, 陈英函, 等. 碳纤维增强聚合物界面相的研究进展[J]. 纤维复合材料, 2023, 40 (4): 81-85.ZHOU Lei, LIU Yuku, CHEN Yinghan, et al. Research progress of interfacial phases of carbon fiber reinforced polymer[J]. Fiber Composites, 2023, 40 (4): 81-85. (in Chinese)

|

| [16] |

JIANG X F, WANG C, LI G, et al. Enhanced interfacial property and thermal conductivity of pitch-based carbon fiber/epoxy compositesvia three-layer assembly of PDI/GN/PDI interphase[J]. Composites Part B: Engineering, 2024, 273 : 111238.

|

| [17] |

TAN Y K, LIU J H, LI Y J, et al. Constructing a new multiscale "soft-rigid-soft" interfacial structure at the interphase to improve the interfacial performance of carbon fiber reinforced polymer composites[J]. Composites Science and Technology, 2024, 248 : 110458.

|

| [18] |

ZHANG Y Y, YANG P W, SUN Y H, et al. Optimization of interfacial properties of different high modulus carbon fiber composites by tailored interphase stiffness with MWNT-EP/epoxy sizing[J]. Surfaces and Interfaces, 2023, 39 : 102977.

|

| [19] |

崔春丽, 徐耀玲. 预测纳米纤维复合材料有效弹性性能的界面模型和界面相模型[J]. 应用数学和力学, 2022, 43 (8): 877-887.CUI Chunli, XU Yaoling. The interface model and the interphase model for predicting the effective elastic properties of nano-fiber composites[J]. Applied Mathematics and Mechanics, 2022, 43 (8): 877-887. (in Chinese)

|

| [20] |

QIU B W, QIU B L, SUN T, et al. Constructing a multiscale rigid-flexible interfacial structure at the interphase by hydrogen bonding to improve the interfacial performance of high modulus carbon fiber reinforced polymer composites[J]. Composites Science and Technology, 2022, 229 : 109672.

|

| [21] |

李美琪, 李晓飞, 王瑞涛, 等. 碳纤维增强聚合物基复合材料界面特性研究进展[J]. 材料导报, 2023, 37 (20): 229-240.LI Meiqi, LI Xiaofei, WANG Ruitao, et al. Research progress on the interface properties of carbon fiber reinforced polymer matrix composites[J]. Materials Reports, 2023, 37 (20): 229-240. (in Chinese)

|

| [22] |

XU W X, WU F, JIAO Y, et al. A general micromechanical framework of effective moduli for the design of nonspherical nano- and micro-particle reinforced composites with interface properties[J]. Materials & Design, 2017, 127 : 162-172.

|

| [23] |

许培俊, 李兆, 郭新良, 等. 热固性树脂过渡层对聚醚砜树脂基碳纤维复合材料界面性能的增强改性[J]. 复合材料学报, 2024, 41 (7): 3568-3576.XU Peijun, LI Zhao, GUO Xinliang, et al. Enhanced modification of interface performance of polyethersulfone resin matrix carbon fiber composite by thermosetting resin transition layer[J]. Acta Materiae Compositae Sinica, 2024, 41 (7): 3568-3576. (in Chinese)

|

| [24] |

MAMOLO S U, SODANO H A. Interfacial reinforcement of carbon fiber composites through a chlorinated aramid nanofiber interphase[J]. Composites Science and Technology, 2024, 245 : 110351.

|

| [25] |

KUNDALWAL S I, MEGUID S A. Micromechanics modelling of the effective thermoelastic response of nano-tailored composites[J]. European Journal of Mechanics A: Solids, 2015, 53 : 241-253.

|

| [26] |

HASSANZADEH-AGHDAM M K, ANSARI R, MAHMOODI M J. Thermo-mechanical properties of shape memory polymer nanocomposites reinforced by carbon nanotubes[J]. Mechanics of Materials, 2019, 129 : 80-98.

|

| [27] |

周金秋, 王振军, 杨思远, 等. 连续石墨纤维增强铝基复合材料准静态拉伸损伤演化与断裂力学行为[J]. 复合材料学报, 2020, 37 (4): 907-918.ZHOU Jinqiu, WANG Zhenjun, YANG Siyuan, et al. Damage evolution and fracture behaviors of continuous graphite fiber reinforced aluminium matrix composites subjected to quasi-static tensile loading[J]. Acta Materiae Compositae Sinica, 2020, 37 (4): 907-918. (in Chinese)

|

| [28] |

SRISUK N. A micromechanics model of thermal expansion coefficient in fiber reinforced composites[D]. Texas: The University of Texas at Arlington, 2010.

|

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号