Thermal Shock Damage Analysis of Refractory Material Based on the DD-OSBPD Model

-

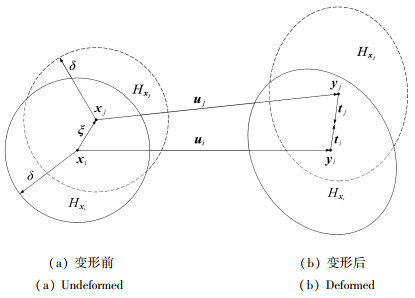

摘要: 提出了一种基于损伤依赖的常规态型近场动力学(damage-dependent ordinary state-based peridynamics, DD-OSBPD)完全热力耦合模型,该模型考虑了因键断裂出现裂纹损伤而产生的新的表面效应,引入键损伤修正因子,对表面修正因子进行二次修正,以提高近场动力学(peridynamics, PD)模型在裂纹损伤处的计算精度,并运用OpenMP并行计算技术实现了对该模型的数值计算. 分别采用DD-OSBPD热力耦合模型,常规态型近场动力学(ordinary state-based peridynamics, OSBPD)热力耦合模型和有限元方法对受均匀拉伸载荷作用的含中心裂纹板的热力耦合问题进行了模拟计算,对DD-OSBPD热力耦合模型的有效性进行了分析验证. 基于DD-OSBPD热力耦合模型,该文对不同淬火温度下陶瓷板的裂纹损伤扩展进行了模拟计算,研究了不同淬火温度对材料抗热冲击性的影响,并与试验结果进行了对比分析,结果表明,数值模拟结果与试验研究结果显示了相同的裂纹扩展规律,且吻合良好,进一步对该模型的正确性进行了验证.Abstract: A fully coupled thermal-mechanical model based on damage dependent ordinary state-based peridynamics (DD-OSBPD) was proposed. In this model, the new surface effects caused by crack damage due to bond breakage were considered, a bond damage correction factor was introduced and a secondary correction was made to the surface correction factor to enhance the computational accuracy of the peridynamics (PD) model at crack damage positions. Additionally, the OpenMP parallel computing technology was employed to implement the numerical calculations for this model. The thermal-mechanical coupling problem of a centrally cracked plate subjected to uniform tensile loading was simulated with the DD-OSBPD thermal-mechanical coupling model, the ordinary state-based peridynamic (OSBPD) thermal-mechanical coupling model and the finite element method, respectively. The results validate the effectiveness of the DD-OSBPD thermal-mechanical coupling model. With the DD-OSBPD thermal-mechanical coupling model, the crack damage propagation in ceramic plates at various quenching temperatures was simulated, and the impact of different quenching temperatures on the material's thermal shock resistance was investigated. Comparison between numerical simulations with experimental studies show the same crack propagation patterns in good agreement, which further confirms the correctness of the model.

-

Key words:

- peridynamics /

- thermal-mechanical coupling /

- crack /

- damage dependent /

- refractory ceramic

-

表 1 含中心裂纹板的材料参数

Table 1. Material properties of a plate with a central crack

material parameter value elastic modulus/GPa 370.0 Poisson’s ratio 0.22 density/(kg/m3) 3 950.0 thermal expansion/K-1 6.8×10-6 heat capacity/(J/(kg·K)) 880.0 thermal conductivity/(W/(m·K)) 20.0 表 2 t=30 μs时,两种PD方法计算结果与有限元法计算结果差异对比

Table 2. At t=30 μs, comparison of the results differences between the 2 PD methods and the finite element method

x/m OSBPD-Ruy/% DD-OSBPD-Ruy/% OSBPD-RΔT/% DD-OSBPD-RΔT/% 0.020 0.64 0.58 3.05 2.89 0.025 0.71 0.64 2.71 2.47 0.030 1.44 1.3 1.84 1.4 0.042 8.69 7.53 22.85 6.96 0.044 5.15 4.24 26.0 10.3 0.046 3.96 3.15 27.31 11.48 0.048 3.49 2.71 27.76 11.84 0.050 3.37 2.60 27.97 12.07 表 3 t=40 μs时,两种PD方法计算结果与有限元法计算结果差异对比

Table 3. At t=40 μs, comparison of the results differences between the 2 PD methods and the finite element method

x/m OSBPD-Ruy/% DD-OSBPD-Ruy/% OSBPD-RΔT/% DD-OSBPD-RΔT/% 0.020 0.04 0.02 2.85 2.66 0.025 0.16 0.04 1.86 1.56 0.030 1.01 0.86 0.95 0.39 0.042 8.29 7.29 24.72 8.81 0.044 4.93 4.19 25.21 8.90 0.046 3.71 3.21 25.24 8.96 0.048 3.41 2.82 25.51 9.25 0.050 3.30 2.71 25.56 9.97 表 4 耐火陶瓷板材料参数

Table 4. Material parameters of the refractory ceramic plate

material parameter value elastic modulus/GPa 370.0 Poisson’s ratio 0.3 density/(kg/m3) 3 980.0 thermal expansion/K-1 7.5×10-6 heat capacity/(J/(kg·K)) 880.0 thermal conductivity/(W/(m·K)) 31.0 critical energy release rate/(J/m2) 24.3 -

[1] 李永全, 彭婷. 中国耐火材料行业发展状况与未来展望[J]. 耐火材料, 2022, 56(5): 435-439.LI Yongquan, PENG Ting. Development status and prospects of China's refractory industry[J]. Refractories, 2022, 56(5): 435-439. (in Chinese) [2] 赵颐, 田晓耕. 基于L-S广义热弹性理论YSZ在超短脉冲下的热力响应[J]. 应用数学和力学, 2023, 44(7): 784-796. doi: 10.21656/1000-0887.430134 ZHAO Yi, TIAN Xiaogeng. Thermomechanical responses of YSZ under ultrashort thermal shock based on the L-S generalized thermoelastic theory[J]. Applied Mathematics and Mechanics, 2023, 44(7): 784-796. (in Chinese) doi: 10.21656/1000-0887.430134 [3] 杨国欣, 郑世风, 李定玉, 等. 考虑损伤判据温度相关性的相场法模拟氧化铝热冲击裂纹扩展[J]. 应用数学和力学, 2022, 43(11): 1259-1267. doi: 10.21656/1000-0887.430133YANG Guoxin, ZHENG Shifeng, LI Dingyu, et al. Thermal shock crack propagation of alumina simulated with the phase-field method under temperature-dependent damage criteria[J]. Applied Mathematics and Mechanics, 2022, 43(11): 1259-1267. (in Chinese) doi: 10.21656/1000-0887.430133 [4] NAWAZ M, NAZIR U, OBAID ALHARBI S, et al. Thermal and solutal analysis in power law fluid under non-Fourier's diffusion conditions[J]. International Communications in Heat and Mass Transfer, 2021, 126: 105331. doi: 10.1016/j.icheatmasstransfer.2021.105331 [5] LIU H, ZHANG K, SHAO S, et al. Numerical investigation on the mechanical properties of Australian strathbogie granite under different temperatures using discrete element method[J]. Rock Mechanics and Rock Engineering, 2019, 52(10): 3719-3735. doi: 10.1007/s00603-019-01814-8 [6] WANG F, KONIETZKY H. Thermal cracking in granite during a heating-cooling cycle up to 1 000℃: laboratory testing and real-time simulation[J]. Rock Mechanics and Rock Engineering, 2022, 55(3): 1411-1428. doi: 10.1007/s00603-021-02740-4 [7] SILLING S A. Reformulation of elasticity theory for discontinuities and long-range forces[J]. Journal of the Mechanics and Physics of Solids, 2000, 48(1): 175-209. doi: 10.1016/S0022-5096(99)00029-0 [8] MADENCI E, OTERKUS E. Peridynamic Theory and Its Applications[M]. New York: Springer, 2014. [9] WANG H, GUO C, WANG F, et al. Peridynamics simulation of structural damage characteristics in rock sheds under rockfall impact[J]. Computers and Geotechnics, 2022, 143: 104625. doi: 10.1016/j.compgeo.2021.104625 [10] ZHOU Z, LI Z, GAO C, et al. Peridynamic micro-elastoplastic constitutive model and its application in the failure analysis of rock masses[J]. Computers and Geotechnics, 2021, 132: 104037. doi: 10.1016/j.compgeo.2021.104037 [11] 周保良, 李志远, 黄丹. 二维瞬态热传导的PDDO分析[J]. 应用数学和力学, 2022, 43(6): 660-668. doi: 10.21656/1000-0887.420150 ZHOU Baoliang, LI Zhiyuan, HUANG Dan. PDDO analysis of 2D transient heat conduction problems[J]. Applied Mathematics and Mechanics, 2022, 43(6): 660-668. (in Chinese) doi: 10.21656/1000-0887.420150 [12] OTERKUS S, MADENCI E, AGWAI A. Peridynamic thermal diffusion[J]. Journal of Computational Physics, 2014, 265: 71-96. doi: 10.1016/j.jcp.2014.01.027 [13] OTERKUS S, MADENCI E, AGWAI A. Fully coupled peridynamic thermomechanics[J]. Journal of the Mechanics and Physics of Solids, 2014, 64: 1-23. [14] D'ANTUONO P, MORANDINI M. Thermal shock response via weakly coupled peridynamic thermo-mechanics[J]. International Journal of Solids and Structures, 2017, 129: 74-89. doi: 10.1016/j.ijsolstr.2017.09.010 [15] CHEN W, GU X, ZHANG Q, et al. A refined thermo-mechanical fully coupled peridynamics with application to concrete cracking[J]. Engineering Fracture Mechanics, 2021, 242: 107463. doi: 10.1016/j.engfracmech.2020.107463 [16] GAO Y, OTERKUS S. Ordinary state-based peridynamic modelling for fully coupled thermoelastic problems[J]. Continuum Mechanics and Thermodynamics, 2019, 31(4): 907-937. doi: 10.1007/s00161-018-0691-1 [17] HE D, HUANG D, WU L, et al. Investigation on thermal failure of functionally graded materials using fully coupled thermo-mechanical peridynamics[J]. Composite Structures, 2023, 305: 116454. doi: 10.1016/j.compstruct.2022.116454 [18] SILLING S A. Fragmentation modeling with EMU[R]. Albuquerque, New Mexico, USA: Computational Phyics Department, Sandia National Laboratories, 2005. [19] SILLING S A, ASKARI E. A meshfree method based on the peridynamic model of solid mechanics[J]. Computers & Structures, 2005, 83(17/18): 1526-1535. [20] BOBARU F, FOSTER J T, GEUBELLE P H, et al. Handbook of Peridynamic Modeling[M]. New York: Chapman and Hall/CRC, 2016. [21] HA Y D, BOBARU F. Characteristics of dynamic brittle fracture captured with peridynamics[J]. Engineering Fracture Mechanics, 2011, 78(6): 1156-1168. doi: 10.1016/j.engfracmech.2010.11.020 [22] 谭洋. 热冲击载荷下功能梯度材料的近场动力学模拟[D]. 武汉: 武汉理工大学, 2021.TAN Yang. Peridynamic simulation of functionally graded materials under thermal shock load[D]. Wuhan: Wuhan University of Technology, 2021. (in Chinese) [23] SILLING S A, EPTON M, WECKNER O, et al. Peridynamic states and constitutive modeling[J]. Journal of Elasticity, 2007, 88(2): 151-184. doi: 10.1007/s10659-007-9125-1 [24] LI J, SONG F, JIANG C. A non-local approach to crack process modeling in ceramic materials subjected to thermal shock[J]. Engineering Fracture Mechanics, 2015, 133: 85-98. -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号